Nano aluminum oxide modified ultra-light cement-based composite material as well as preparation method and application thereof

A technology of nano-alumina and composite materials, which is applied in the field of nano-alumina modified ultra-light cement-based composite materials and its preparation, and can solve problems such as poor contact between raw materials and cement slurry matrix, affecting the mechanical properties of materials, and affecting compactness, etc. , to achieve the effects of dense hydration products, improving mechanical properties, and accelerating the hydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

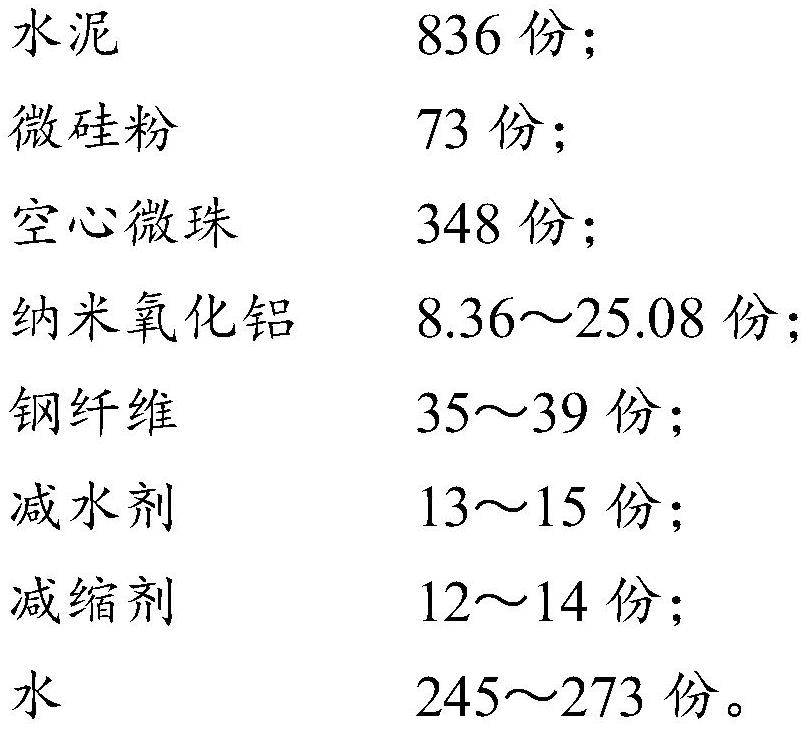

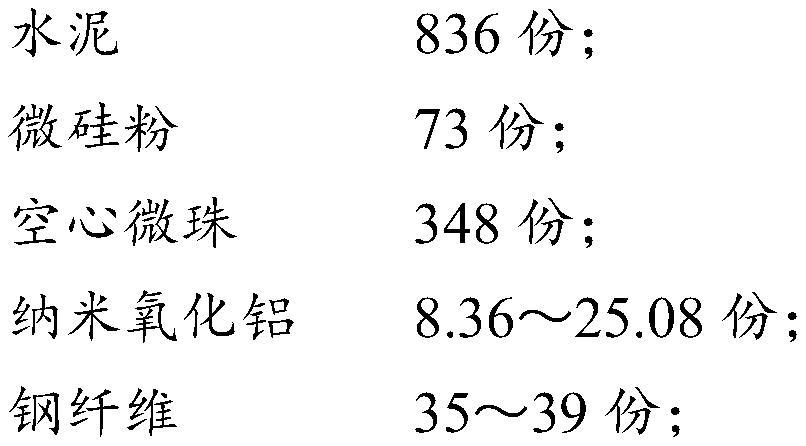

[0047] A nano-alumina modified ultra-light cement-based composite material, comprising the following components in parts by weight: 836 parts of cement, 73 parts of micro-silica fume, 348 parts of hollow microspheres, 8.36 parts of nano-alumina, and 39 parts of steel fiber Parts, 13 parts of water reducing agent, 14 parts of shrinkage reducing agent, 245 parts of water.

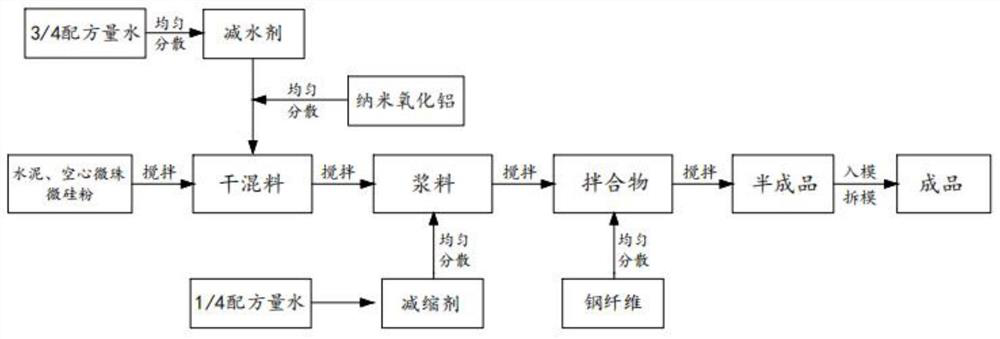

[0048] Such as figure 1 As shown, the preparation method of the nano-alumina modified ultra-light cement-based composite material comprises the following steps:

[0049] S1. Weigh 836kg of cement, 73kg of microsilica fume and 348kg of hollow microspheres, pour them into a forced mixer, stir for 3 minutes at a speed of 48rpm / min and mix evenly to obtain a dry mix;

[0050] S2. Weigh 13kg of water reducer and 8.36kg of nano-alumina, add 183.75kg of water to the water-reducer, and after uniform dispersion, add nano-alumina to the diluted water-reducer, and after uniform dispersion, Then add the mixture of nano...

Embodiment 2

[0055] A nano-alumina modified ultra-light cement-based composite material, comprising the following components in parts by weight: 836 parts of cement, 73 parts of micro-silica fume, 348 parts of hollow microspheres, 25.08 parts of nano-alumina, and 39 parts of steel fiber Parts, 13 parts of water reducing agent, 14 parts of shrinkage reducing agent, 245 parts of water.

[0056] Such as figure 1 As shown, the preparation method of the nano-alumina modified ultra-light cement-based composite material comprises the following steps:

[0057] S1. Weigh 836kg of cement, 73kg of microsilica fume and 348kg of hollow microspheres, pour them into a forced mixer, stir for 3 minutes at a speed of 48rpm / min and mix evenly to obtain a dry mix;

[0058] S2. Weigh 13kg of water reducer and 25.08kg of nano-alumina, add 183.75kg of water to the water reducer, and after uniform dispersion, add nano-alumina to the diluted water reducer, and after uniform dispersion, Then add the mixture of na...

Embodiment 3

[0063] A nano-alumina modified ultra-light cement-based composite material, comprising the following components in parts by weight: 836 parts of cement, 73 parts of micro-silica fume, 348 parts of hollow microspheres, 8.36 parts of nano-alumina, and 35 parts of steel fiber Parts, 15 parts of water reducing agent, 12 parts of shrinkage reducing agent, 273 parts of water.

[0064] Such as figure 1 As shown, the preparation method of the nano-alumina modified ultra-light cement-based composite material comprises the following steps:

[0065] S1. Weigh 836kg of cement, 73kg of microsilica fume and 348kg of hollow microspheres, pour them into a forced mixer, stir for 5 minutes at a speed of 48rpm / min and mix evenly to obtain a dry mix;

[0066] S2. Weigh 15kg of water reducer and 8.36kg of nano-alumina, add 204.75kg of water to the water reducer, and after uniform dispersion, add nano-alumina to the diluted water reducer, and after uniform dispersion, Then add the mixture of nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com