Medium-speed coal mill and medium-speed coal milling method suitable for high-moisture lignite

A high-moisture, coal mill technology, applied in the direction of grain processing, etc., can solve the problems of coal mill wear, air volume and coal volume mismatch, coal mill outlet temperature low, etc., to achieve high reliability and grinding device selection Reasonable and avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

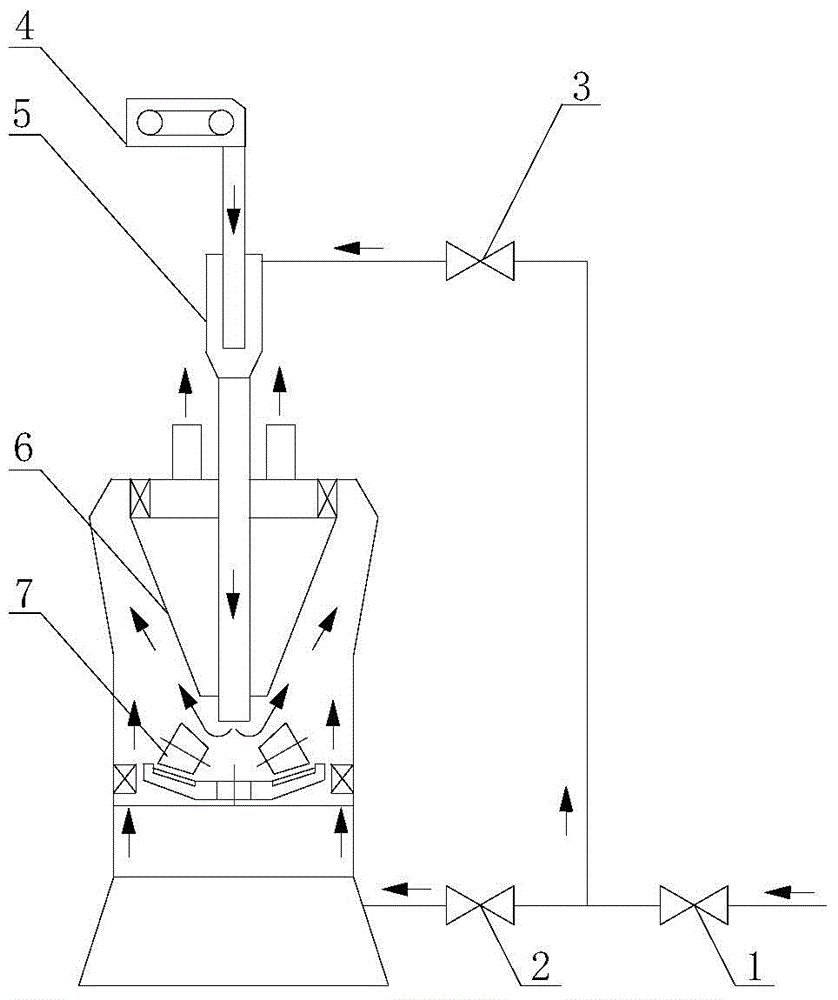

[0020] refer to figure 1 , the medium-speed pulverizer suitable for high-moisture lignite of the present invention includes a hot air door 1, a grinding device 7, a coarse powder separator 6, a pre-drying device 5 and a coal feeder 4, and the outlet of the hot air door 1 is divided into Two roads, wherein, one road is connected with the air inlet of the pre-drying device 5, the other road is connected with the air inlet of the grinding device 7, the outlet of the coal feeder 4 is connected with the lignite inlet of the pre-drying device 5, and the pre-drying device 5 The outlet of the coarse powder separator 6 and the opening at the bottom of the coarse powder separator 6 are all located directly above the grinding device 7, the outlet of the hot air door 1 is connected with the air inlet of the pre-drying device 5 through the bypass damper 3, and the outlet of the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com