Static and dynamic performance design method of closed high-speed water lubrication dynamic pressure spiral groove thrust bearing

A technology of thrust bearing and design method, which is applied to bearings, liquid cushion bearings, shafts and bearings, etc., can solve the problems of inaccurate description of dynamic behavior of high-speed water-lubricated dynamic pressure spiral groove thrust bearings, low calculation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0070] Such as Figure 7 As shown, the content of the static and dynamic performance design method of the high-speed water-lubricated dynamic pressure spiral groove thrust bearing of this embodiment is given, which mainly includes the following steps:

[0071] s1: Considering the coupling effects of multiple factors such as cavitation effect, centrifugal effect, turbulent flow effect and thermal effect, a closed high-speed water-lubricated dynamic pressure spiral groove thrust bearing lubrication model is established:

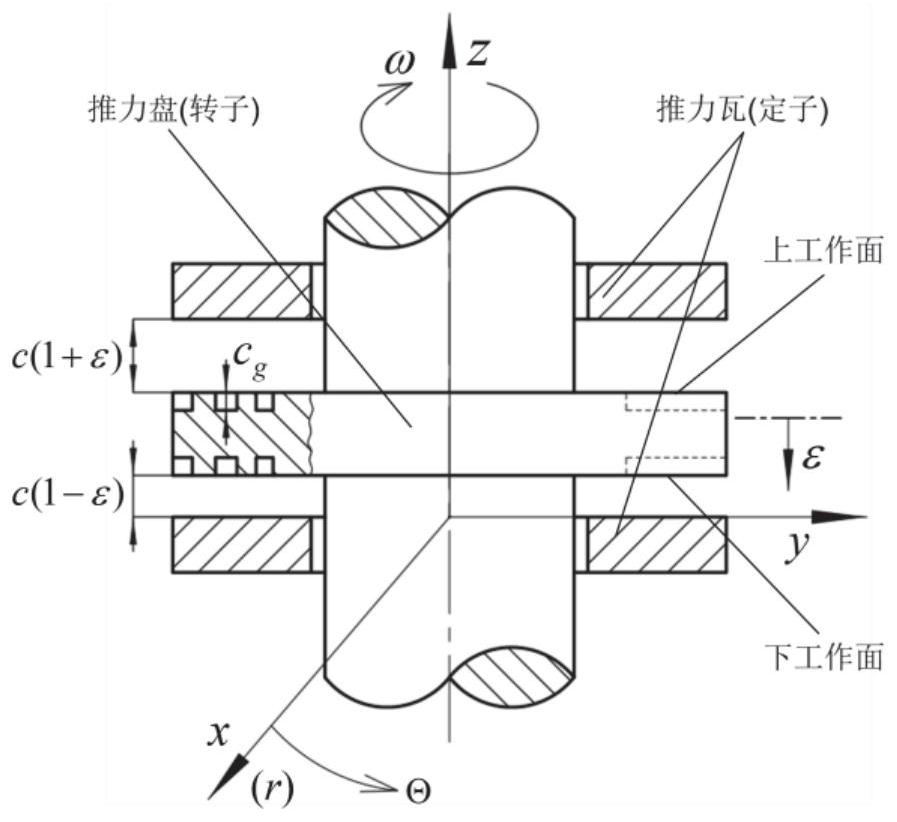

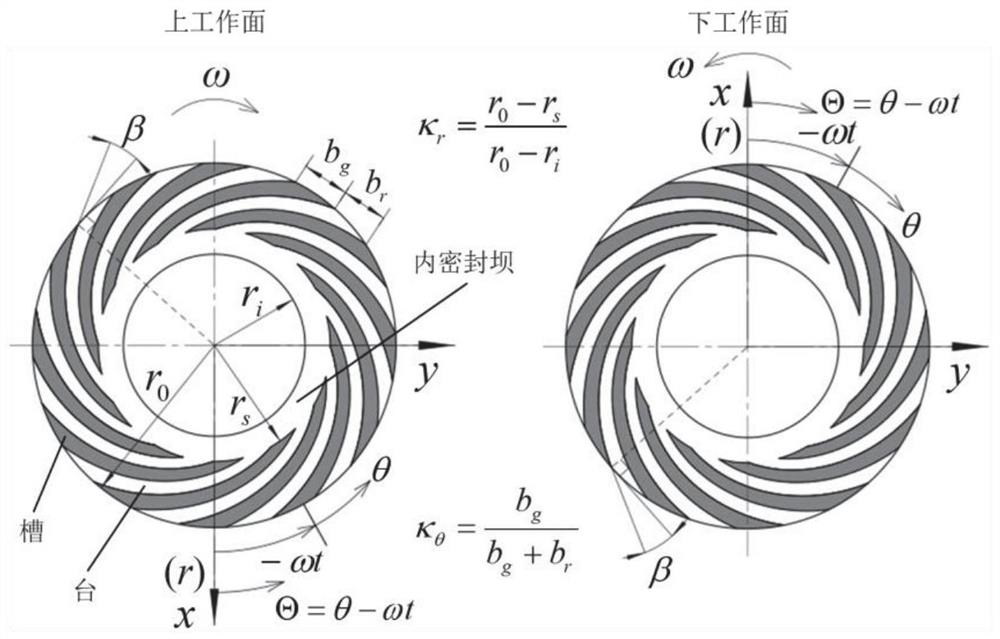

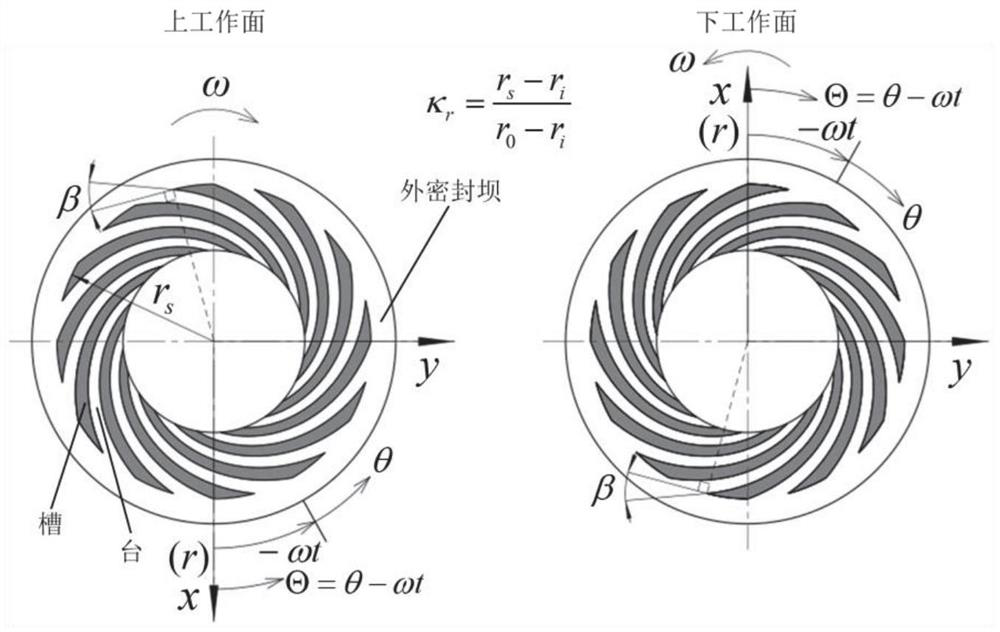

[0072] The geometric structure of the closed high-speed water-lubricated dynamic pressure spiral groove thrust bearing is as follows: figure 1 As shown, the thrust bearing is composed of two opposite fixed thrust pads and a clockwise rotating thrust disk; the upper and lower working surfaces of the thrust disk are engraved with peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com