Up-to-standard discharge for low-concentration copper-containing wastewater in semiconductor industry and efficient sedimentation process thereof

A low-concentration, semi-conductor technology, applied in the direction of water pollutants, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of substandard effluent, large dosage of ozone, and increased cost of chemicals, etc. The effect of increasing the ground area, accelerating the settlement speed, and increasing the surface load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

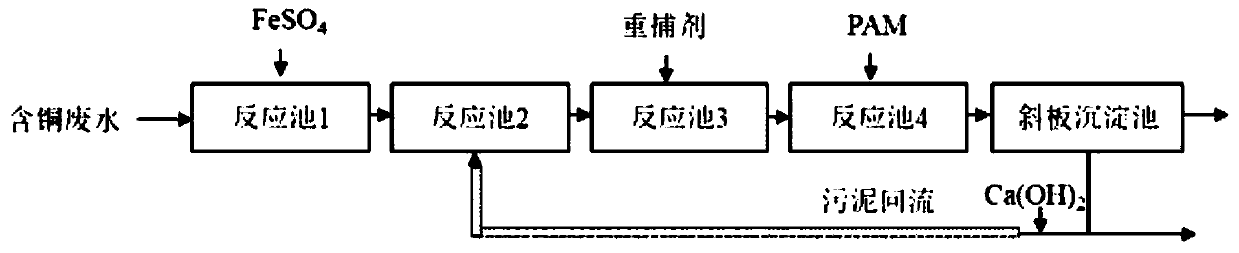

[0041] The water quality of copper-containing wastewater in a semiconductor factory: the content of suspended solids (SS) is 50-100 mg / L, the concentration of copper ions is 7-10 mg / L, and the concentration of complexed copper is 4-5 mg / L. 2 o 2 The concentration is 1000~1100mg / L, and the pH is 3~4. The waste water flow rate is 20t / h, and it operates 24 hours a day. The implementation steps of this case are as follows:

[0042] The first step: directly add 10% FeSO to the low-concentration copper-containing wastewater 4 solution; reaction time 25-30min, 10% FeSO 4 The solution dosage is 16L / h (FeSO 4 : total copper=8 (mass ratio)).

[0043] The second step: the return copper-containing sludge and the copper-containing wastewater react in the second reaction tank 2. By adding calcium hydroxide solution at the inlet of the pipeline mixer, the pH of the second reaction tank 2 is maintained at 10-12, and the reaction 10~15min, the flow rate of copper-containing sludge is 5~1...

Embodiment 2

[0049] The water quality of copper-containing wastewater in a semiconductor factory: the content of suspended solids is 50-150 mg / L, the concentration of copper ions is 10-15 mg / L, the concentration of complexed copper is 5-8 mg / L, H 2 o 2 The concentration is 400-500 mg / L, and the pH is 2-3. The waste water flow rate is 30t / h, and it operates 24 hours a day. The implementation steps of this case are as follows:

[0050] The first step: directly add 10% FeSO to the low-concentration copper-containing wastewater 4 solution; reaction time 25-30min, 10% FeSO 4 The solution dosage is 21L / h (FeSO 4 : total copper=9 (mass ratio)).

[0051] The second step: the return copper-containing sludge and the copper-containing wastewater react in the second reaction tank 2. By adding calcium hydroxide solution at the inlet of the pipeline mixer, the pH of the second reaction tank 2 is maintained at 10-12, and the reaction 15-20min, the copper-containing sludge flow rate is 8-16m 3 / h; ...

Embodiment 3

[0057] The water quality of copper-containing wastewater in a semiconductor factory: the content of suspended solids is 20-50 mg / L, the concentration of copper ions is 3-5 mg / L, the concentration of complexed copper is 2-3 mg / L, H 2 o 2 The concentration is 300-500 mg / L, and the pH is 2-4. The waste water flow rate is 40t / h, and it operates 24 hours a day. The implementation steps of this case are as follows:

[0058] The first step: directly add 10% FeSO to the low-concentration copper-containing wastewater 4 solution; reaction time 25-30min, 10% FeSO 4 The solution dosage is 20L / h (FeSO 4 : total copper=10 (mass ratio)).

[0059] The second step: the return copper-containing sludge and the copper-containing wastewater react in the second reaction tank 2. By adding calcium hydroxide solution at the inlet of the pipeline mixer, the pH of the second reaction tank 2 is maintained at 10-12, and the reaction 10~15min, the flow rate of copper-containing sludge is 10~15m 3 / h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com