Anticorrosive terminal material, anticorrosive terminal, and electric wire end structure

An anti-corrosion and terminal technology, which is applied in the direction of circuits, contact parts, electrical components, etc., can solve the problems of poor productivity of Sn-Zn alloy plating and disappearance of anti-corrosion effect of aluminum wires, etc., and achieve excellent long-term corrosion resistance and suppression of foreign species Metal contact corrosion and the effect of suppressing the increase of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

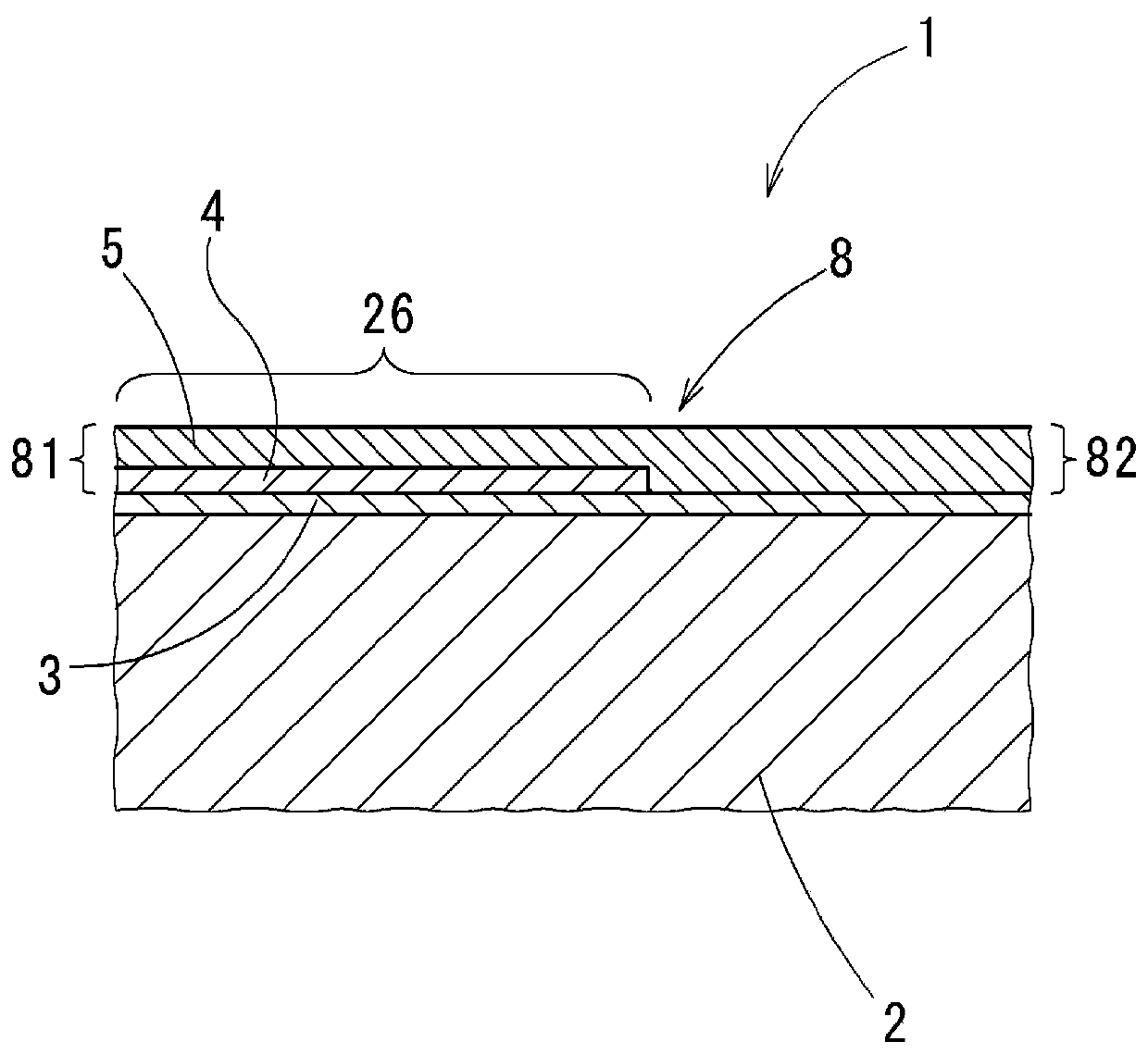

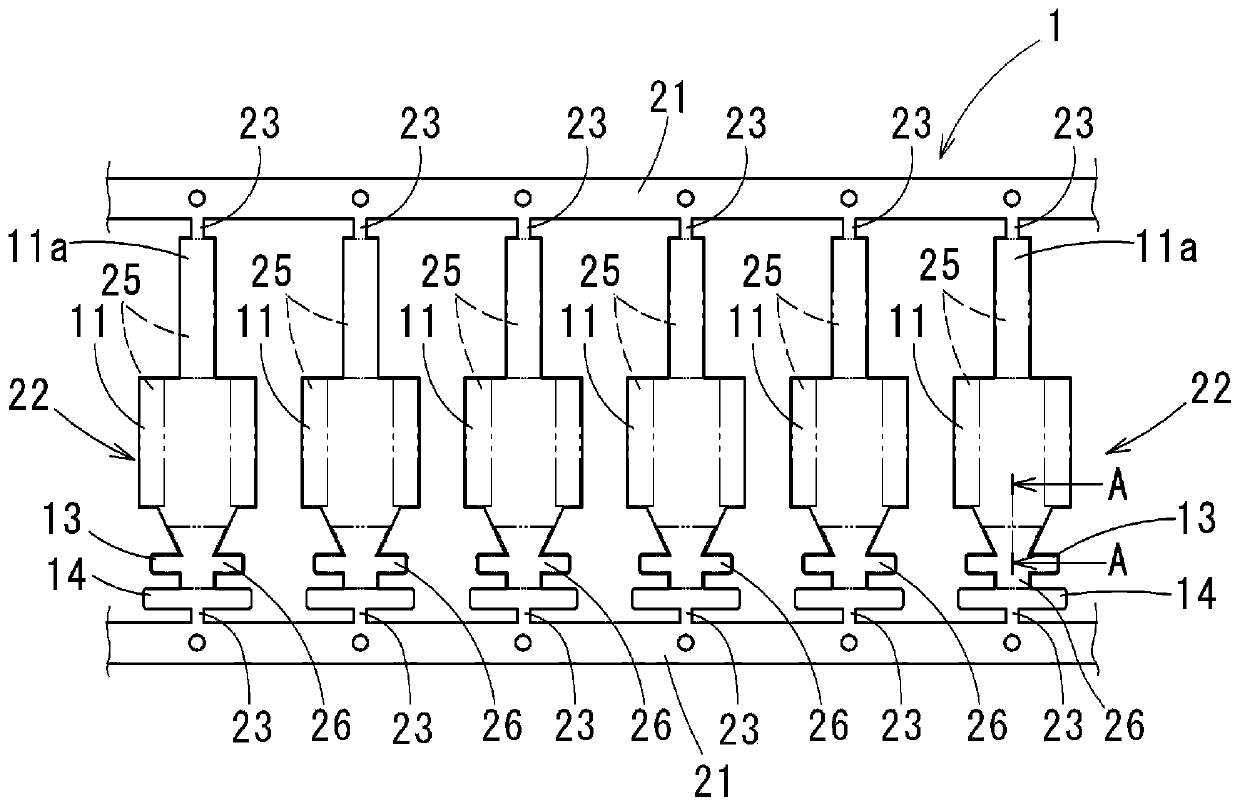

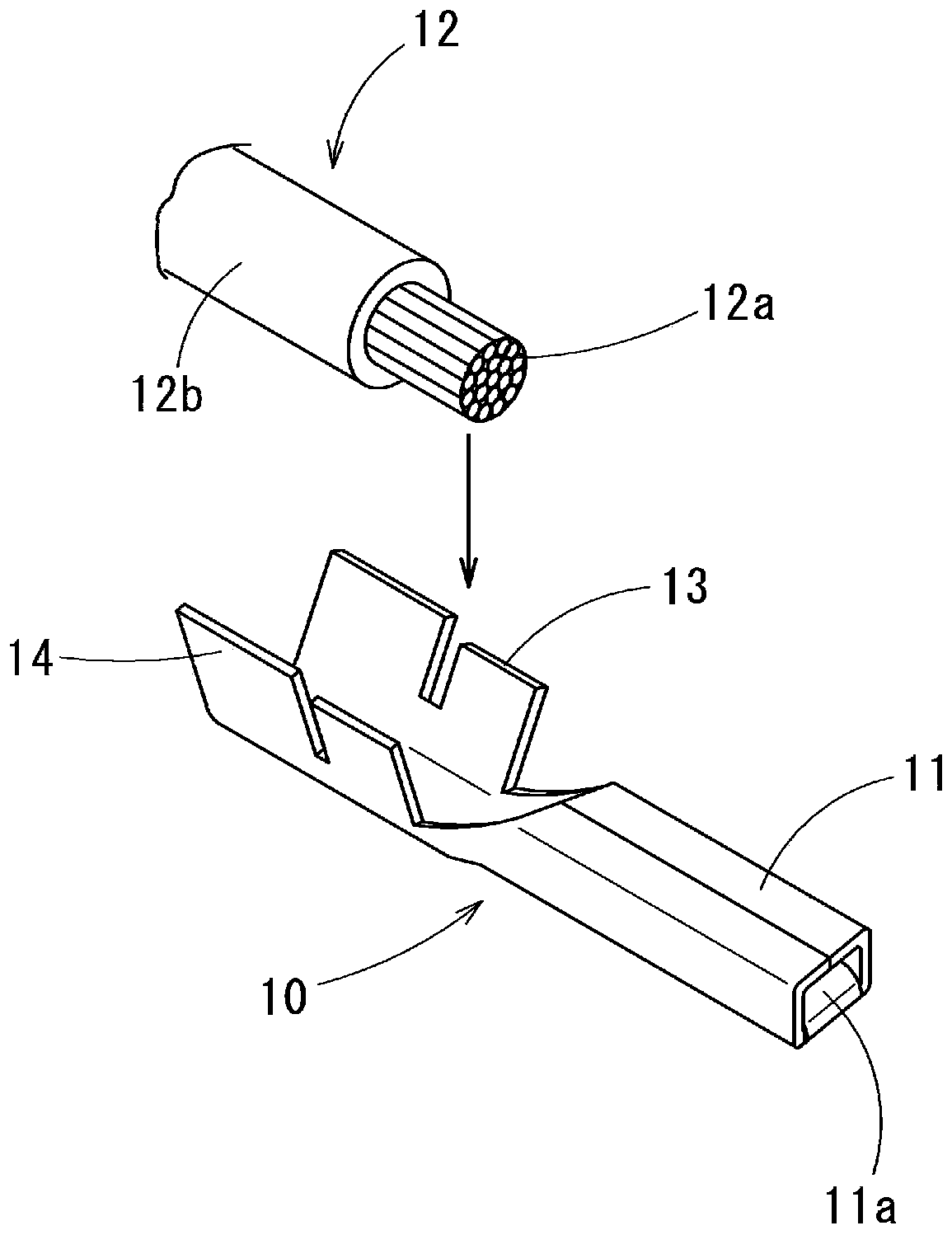

[0088] A copper plate of C1020 is used as the base material, and the copper plate is stamped into figure 2 The strip material shown, and after degreasing, pickling, and nickel plating in the case of forming the bottom layer, after that, removing figure 2 Except for the predetermined contact part 25, zinc alloy plating is implemented. Then, tin plating was performed on the entire surface. Then, this plated copper plate was heat-treated at a temperature of 30° C. to 190° C. within a range of 1 hour to 36 hours to obtain samples 1 to 16 of anticorrosion terminal materials shown in Table 1.

[0089] As a comparative example, the following samples were also produced: Sample 18 in which a zinc layer was formed in a short time and at a low current density when galvanizing was performed on the part where the core wire is to be contacted; Sample 19 was galvanized on the entire surface, and the zinc layer was also formed on the planned contact part; and the part other than the plann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com