Preparation method of antirust powder metallurgy material

A powder metallurgy and iron powder technology, applied in the field of preparation of anti-rust powder metallurgy materials, can solve the problems of energy waste, production efficiency, low tensile strength and hardness, and many process steps, and achieve enhanced anti-corrosion, excellent mechanical properties, The effect of enhancing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

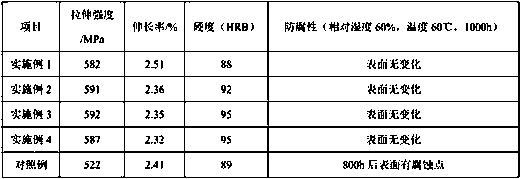

Examples

Embodiment 1

[0019] A method for preparing an antirust powder metallurgy material, comprising the following steps:

[0020] Step 1, stirring and mixing 10 parts of copper powder, 10 parts of iron powder, 2 parts of zinc powder, 3 parts of glass fiber and 2 parts of carbon powder in a mixing device to obtain a mixture 1;

[0021] Step 2, add 1 part of aluminum oxide, 2 parts of epoxy resin, 1 part of calcium oxide, 2 parts of lecithin and 1 part of 3-acrylamidopropyl dimethyl ammonium chloride in the mixture one, and the vacuum degree is Heating to 80°C under a vacuum condition of 0.02MPa and keeping it for 20 minutes to obtain the mixture 2;

[0022] Step 3, mixing the mixture 1 and the mixture 2, and grinding and mixing by a ball mill, the grinding and mixing time is 20-30 minutes, and the particle size of the mixture 3 after grinding is below 200 μm, and the mixture 3 is obtained;

[0023] Step 4, pressing the mixture three in a mold to obtain a blank;

[0024] Step 5: Send the billet ...

Embodiment 2

[0027] A method for preparing an antirust powder metallurgy material, comprising the following steps:

[0028] Step 1, stirring and mixing 13 parts of copper powder, 14 parts of iron powder, 3 parts of zinc powder, 5 parts of glass fiber and 4 parts of carbon powder in a mixing device to obtain a mixture 1;

[0029] Step 2, add 2 parts of aluminum oxide, 5 parts of epoxy resin, 2 parts of calcium oxide, 3 parts of lecithin and 2 parts of 3-acrylamidopropyl dimethyl ammonium chloride in the mixture one, in vacuum degree is Heating to 86°C under a vacuum condition of 0.03MPa, and keeping it for 30 minutes, to obtain the mixture 2;

[0030] Step 3, mixing the mixture 1 and the mixture 2, and grinding and mixing by a ball mill, the grinding and mixing time is 25 minutes, and the particle size of the mixture 3 after grinding is 200 μm or less, and the mixture 3 is obtained;

[0031] Step 4, pressing the mixture three in a mold to obtain a blank;

[0032] Step 5: Send the billet i...

Embodiment 3

[0035] A method for preparing an antirust powder metallurgy material, comprising the following steps:

[0036] Step 1, stirring and mixing 17 parts of copper powder, 14 parts of iron powder, 4 parts of zinc powder, 6 parts of glass fiber and 4 parts of carbon powder in a mixing device to obtain a mixture 1;

[0037] Step 2, add 2 parts of aluminum oxide, 6 parts of epoxy resin, 2 parts of calcium oxide, 4 parts of lecithin and 3 parts of 3-acrylamidopropyl dimethyl ammonium chloride in the mixture one, in vacuum degree is Heating to 95°C under a vacuum condition of 0.04MPa and keeping it for 36 minutes to obtain the mixture 2;

[0038] Step 3, mixing the mixture 1 and the mixture 2, and grinding and mixing by a ball mill, the grinding and mixing time is 28 minutes, and the particle size of the mixture 3 after grinding is 200 μm or less, and the mixture 3 is obtained;

[0039] Step 4, pressing the mixture three in a mold to obtain a blank;

[0040] Step 5: Send the billet int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com