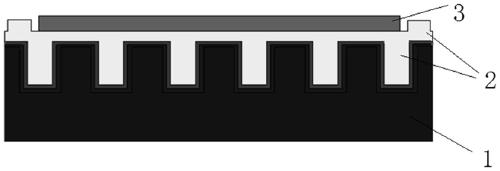

Pretreatment method of TSV blind hole electro-coppering hard warped wafer before chemical mechanical polishing

A chemical mechanical and electroplating copper technology, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of automatic feeding of equipment, poor polishing uniformity, uncontrollable direction, etc., so as to avoid automatic feeding of equipment and realize The effect of global flattening and reducing the thickness of the glue layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0031] The pretreatment method before chemical mechanical polishing of TSV blind hole electroplating copper hard warping wafer of the present invention comprises the following steps,

[0032] Step 1. Spray a layer of positive photoresist or negative photoresist on the graphics surface of the TSV copper-plated hard-warped wafer to completely cover the electroplated surface copper, copper bumps or copper bumps ;

[0033] Step 2: Cover the central position of the wafer with a matching mask to leak out the edge area; perform directional exposure on the leaked area at the edge of the wafer through an exposure machine; use a developing solution to expose the hard warped edge area of the TSV blind hole electroplating copper Perform development to remove the photoresist in this area, exposing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com