Acrylic acid modified waterborne polyurethane self-repairing pressure-sensitive adhesive as well as preparation method and application thereof

A water-based polyurethane and acrylic technology, used in polyurea/polyurethane adhesives, adhesives, ester copolymer adhesives, etc., can solve the problems of easy residual glue, poor high temperature resistance, poor water resistance, etc., and achieve adhesion improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A preparation method of acrylic modified water-based polyurethane self-repairing pressure-sensitive adhesive, comprising the following steps:

[0077] (1) Under the conditions of 120°C and -0.1MPa, vacuum dewater polytetrahydrofuran ether glycol 2000 and dimethylol propionic acid;

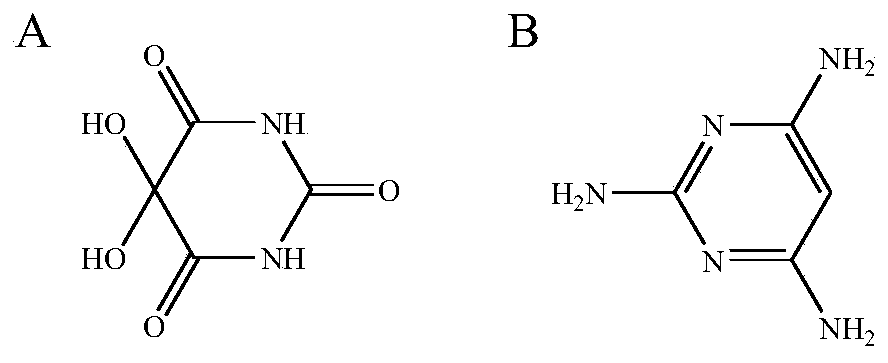

[0078] (2) Take dry polytetrahydrofuran ether diol 2000 (20g, 10mmol), dimethylolpropionic acid (2.00g, 14.91mmol), hexamethylene diisocyanate (10.00g, 59.46mmol), alloxan- Hydrate (2.00g, 12.49mmol), dibutyltin dilaurate (0.09g, 0.14mmol), antioxidant 1135 (0.10g, 0.26mmol) and acetone 30mL were added to a four-necked flask, heated to 86°C, and stirred for 3.5 h; wherein, the structural formula of alloxan monohydrate is as figure 1 Shown in Figure A.

[0079] (3) Cool down to below 55°C, add 2,4,6-triaminopyrimidine (1.56g, 12.48mmol) and trimethylolpropane (0.8g, 5.96mmol) to the reaction system in step (2), and heat up to 70°C, stirring reaction for 2h; wherein, the structural formula ...

Embodiment 2

[0085] A preparation method of acrylic modified water-based polyurethane self-repairing pressure-sensitive adhesive, comprising the following steps:

[0086] (1) Under the conditions of 120°C and -0.1MPa, vacuum dewater polytetrahydrofuran ether glycol 2000 and dimethylol propionic acid;

[0087] (2) Take dry polytetrahydrofuran ether diol 2000 (20g, 10mmol), dimethylolpropionic acid (2.00g, 14.91mmol), hexamethylene diisocyanate (10.00g, 59.46mmol), alloxan- Hydrate (2.00g, 12.49mmol), dibutyltin dilaurate (0.09g, 0.14mmol), antioxidant 1135 (0.10g, 0.26mmol) and acetone 30mL were added to a four-necked flask, heated to 86°C, and stirred for 3.5 h; wherein, the structural formula of alloxan monohydrate is as figure 1 Shown in Figure A.

[0088] (3) Cool down to below 55°C, add 2,4,6-triaminopyrimidine (1.56g, 12.48mmol) and trimethylolpropane (0.8g, 5.96mmol) to the reaction system in step (2), and heat up to 70°C, stirring reaction for 2h; wherein, the structural formula ...

Embodiment 3

[0094] A preparation method of acrylic modified water-based polyurethane self-repairing pressure-sensitive adhesive, comprising the following steps:

[0095] (1) Under the conditions of 120°C and -0.1MPa, remove water from polyethylene glycol 1000 and dimethylol propionic acid in vacuum;

[0096](2) Take dry polyethylene glycol 1000 (10g, 10mmol), dimethylolpropionic acid (2.00g, 14.91mmol), hexamethylene diisocyanate (10.00g, 59.46mmol), alloxan monohydrate (2.00g, 12.49mmol), dibutyltin dilaurate (0.09g, 0.14mmol), antioxidant 1135 (0.10g, 0.26mmol) and acetone 30mL were added to a four-necked flask, heated to 86°C, and stirred for 3.5h; Wherein, the structural formula of alloxan monohydrate is as follows figure 1 Shown in Figure A.

[0097] (3) Cool down to below 55°C, add 2,4,6-triaminopyrimidine (1.56g, 12.48mmol) and trimethylolpropane (0.8g, 5.96mmol) to the reaction system in step (2), and heat up to 70°C, stirring reaction for 2h; wherein, the structural formula of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com