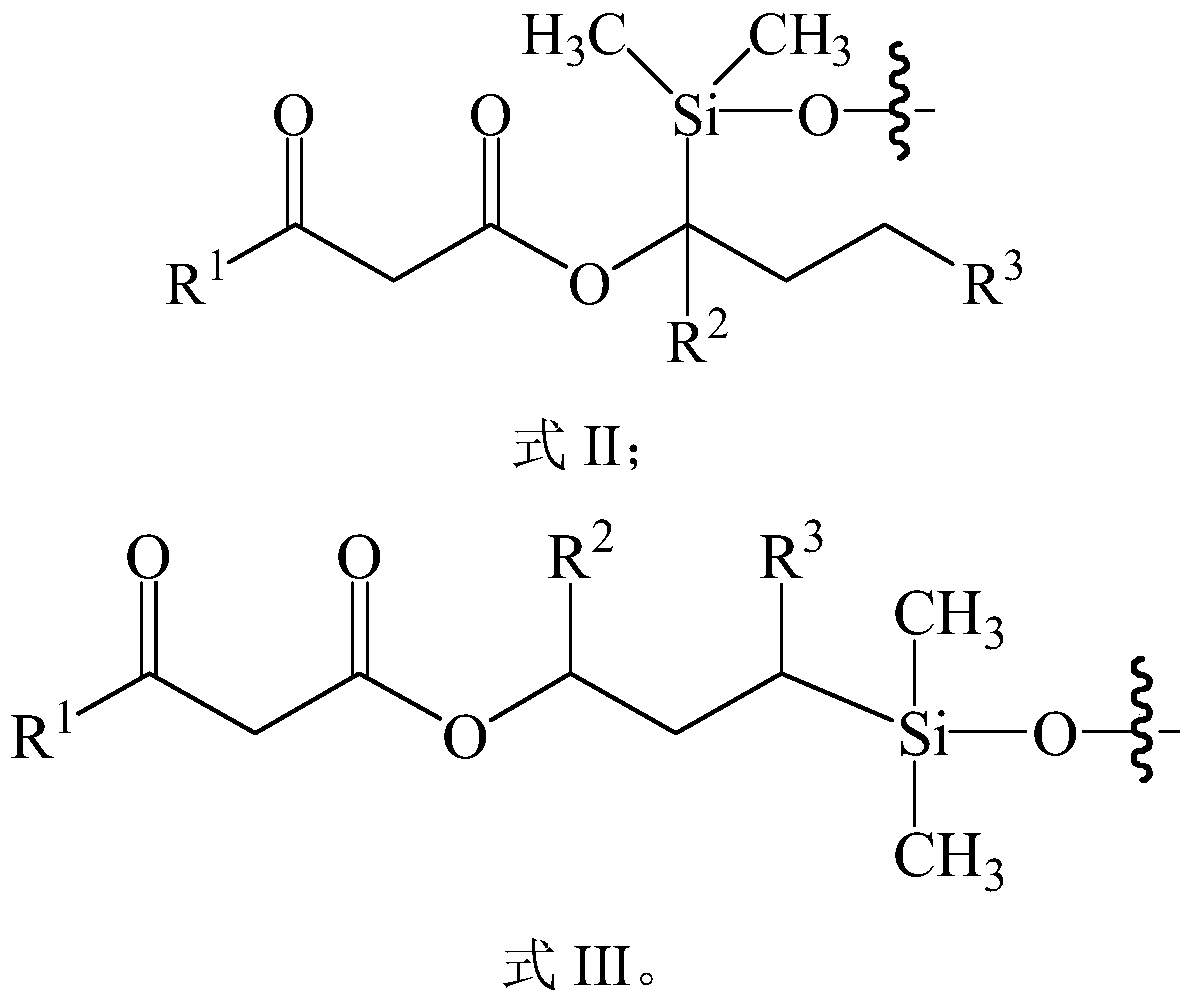

Modified MQ resin, and preparation method and application thereof

A MQ silicone resin, modified technology, applied in the direction of adhesives, etc., can solve the problem of adding more components, to achieve the effect of improving strength, good bonding effect, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A modified MQ resin, the preparation method is as follows:

[0060] (1) Synthesis of hydrogen-containing MQ silicone resin

[0061] Add 240g of methyl MQ silicone resin (M / Q=0.9, Si-OH=1.8wt%), 1,1,3,3-tetramethyldi 11.3g of siloxane and 160g of n-hexane were stirred and heated to 45°C under nitrogen protection in a flask, 1.2g of trifluoromethanesulfonic acid and 0.15g of distilled water were added thereto, and the reaction was stirred at about 70°C for 6h. Then, cool to 50° C., add dimethylformamide to precipitate the catalyst, and then stir the reaction mixture at 50° C. for 1 h. Cool to room temperature, add 10 g of sodium bicarbonate for neutralization, filter, and concentrate under reduced pressure to a solid content of 70% (309 g, the mass fraction of Si-H groups in chemical analysis is 0.10%).

[0062] (2) Preparation of modified MQ resin

[0063] Add 12.8 g of allyl acetoacetate and 0.27 g of platinum catalyst into a four-necked flask equipped with a stirrer...

Embodiment 2

[0065] A modified MQ resin, the preparation method is as follows:

[0066] (1) Synthesis of hydrogen-containing MQ silicone resin

[0067] Add 240 g of methyl MQ silicone resin (M / Q=1.0, Si-OH=2wt%), 1,1,3,3-tetramethyldisilazol into a four-necked flask equipped with a stirrer, condenser and thermometer 20.9g of oxane and 160g of n-hexane were stirred and heated to 46°C under nitrogen protection in a flask, 1.2g of trifluoromethanesulfonic acid and 0.20g of distilled water were added thereto, and the reaction was stirred at about 70°C for 6h. Then, cool to 50° C., add dimethylformamide to precipitate the catalyst, and then stir the reaction mixture at 50° C. for 1 h. Cool to room temperature, add 10 g of sodium bicarbonate for neutralization, filter, and concentrate under reduced pressure to a solid content of 70% (341 g, the mass fraction of Si-H groups by chemical analysis is 0.11%).

[0068] (2) Preparation of modified MQ resin

[0069] Add 14.2 g of allyl acetoacetate a...

Embodiment 3

[0071] A modified MQ resin, the preparation method is as follows:

[0072] (1) Synthesis of hydrogen-containing MQ silicone resin

[0073] Add 240 g of methyl MQ silicone resin (M / Q=0.6, Si-OH=3wt%), 1,1,3,3-tetramethyldisilazol into a four-necked flask equipped with a stirrer, condenser, and thermometer 31.2g of oxane and 160g of n-hexane were stirred and heated to 46°C under nitrogen protection in a flask, 1.5g of trifluoromethanesulfonic acid and 0.30g of distilled water were added thereto, and the reaction was stirred at about 70°C for 6h. Then, cool to 50° C., add dimethylformamide to precipitate the catalyst, and then stir the reaction mixture at 50° C. for 1 h. Cool to room temperature, add 10 g of sodium bicarbonate to neutralize, filter, and concentrate under reduced pressure to a solid content of 70% (348 g, the mass fraction of Si-H groups in chemical analysis is 0.15%).

[0074] (2) Preparation of modified MQ resin

[0075] Add 9.4 g of allyl acetoacetate and 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com