A low-nickel nitrogen-containing austenitic stainless steel flux-cored wire and preparation method thereof

A technology of austenitic stainless steel and flux-cored wire, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as hot cracks in the weld zone, nitride pitting in the zone, loss of nitrogen elements, etc., and achieve excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

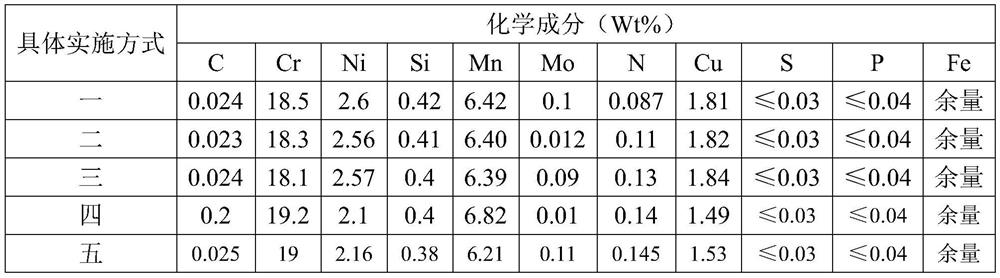

[0026] Embodiment 1: A low-nickel nitrogen-containing austenitic stainless steel flux-cored wire in this embodiment is prepared from a flux core and a stainless steel sheath (a SUS430 stainless steel strip with a width of 9.8 mm and a thickness of 0.4 mm). No gas protection is required;

[0027] The drug core is formed by mixing alloy components and slag, and the sum of the mass fractions of each component in the drug core is 100%;

[0028] The alloy components are composed of electrolytic manganese: 28%, ferrosilicon: 2.5%, metal chromium: 16%, metal nickel: 12.5%, molybdenum ferro: 0.8%, copper powder: 8.5% and ferrochromium nitride powder according to the mass fraction : 6% mixed;

[0029] The slag is composed of composite fluoride: 5%, carbonate mixture: 3%, potassium feldspar: 2%, rutile: 10.7%, zircon sand: 2% and Al-Mg alloy: 3% by mass fraction made.

[0030] The composite fluoride is formed by mixing barium fluoride: sodium fluoride: magnesium fluoride: calcium flu...

specific Embodiment approach 2

[0039] Embodiment 2: A low-nickel nitrogen-containing austenitic stainless steel flux-cored wire in this embodiment is prepared from a flux core and a stainless steel sheath (a SUS430 stainless steel strip with a width of 9.8mm and a thickness of 0.4mm). No gas protection is required;

[0040] The drug core is formed by mixing alloy components and slag, and the sum of the mass fractions of each component in the drug core is 100%;

[0041] The alloy components are composed of electrolytic manganese: 28%, ferrosilicon: 2.5%, metal chromium: 15%, metal nickel: 12.2%, molybdenum ferro: 0.8%, copper powder: 8.5% and ferrochromium nitride powder according to the mass fraction : 7% mixed;

[0042] The slag is composed of composite fluoride: 6%, carbonate mixture: 2%, potassium feldspar: 2%, rutile: 11%, zircon sand: 2% and Al-Mg alloy: 3% by mass fraction made.

[0043] The composite fluoride is formed by mixing barium fluoride: sodium fluoride: magnesium fluoride: calcium fluorid...

specific Embodiment approach 3

[0052] Specific embodiment three: a low-nickel nitrogen-containing austenitic stainless steel flux-cored wire in this embodiment is prepared from a flux core and a stainless steel sheath (a SUS430 stainless steel strip with a width of 9.8 mm and a thickness of 0.4 mm). No gas protection is required;

[0053]The drug core is formed by mixing alloy components and slag, and the sum of the mass fractions of each component in the drug core is 100%;

[0054] The alloy components are composed of electrolytic manganese: 28%, ferrosilicon: 2.5%, metal chromium: 14%, metal nickel: 12.2%, molybdenum ferro: 0.8%, copper powder: 8.5% and ferrochromium nitride powder according to the mass fraction : 8% mixed;

[0055] The slag is composed of composite fluoride: 7%, carbonate mixture: 1%, potassium feldspar: 2%, rutile: 12%, zircon sand: 2% and Al-Mg alloy: 2% by mass fraction made.

[0056] The composite fluoride is formed by mixing barium fluoride: sodium fluoride: magnesium fluoride: c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com