A kind of low-nickel nitrogen-containing austenitic stainless steel electrode and preparation method thereof

A technology of austenitic stainless steel and stainless steel, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of low low-temperature impact toughness and poor pitting resistance, so as to promote grain refinement and reduce ferrite Opportunities for the formation of body and deformed martensite, and the effect of improving pitting corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

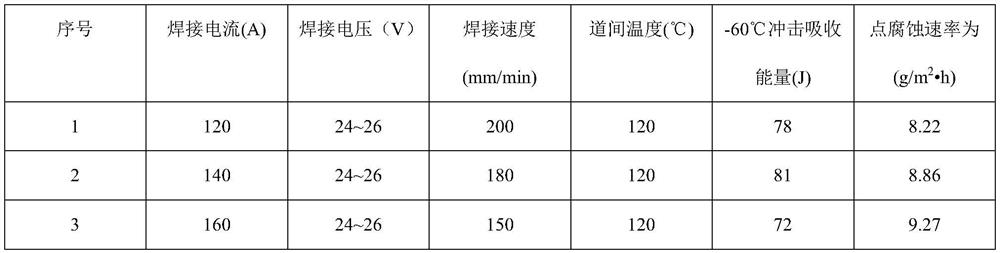

Examples

specific Embodiment approach 1

[0021] Embodiment 1: The chemical composition and mass percentage of a low-nickel nitrogen-containing austenitic stainless steel electrode in this embodiment are C: 0.024%, Si: 0.42%, Mn: 6.01%, P: 0.022%, S: 0.008%, Cr: 17.87%, Ni: 2.55%, Mo: 0.02%, Cu: ≤0.01%, N: 0.26%, and the balance is Fe.

[0022] The method for preparing the above-mentioned low-nickel nitrogen-containing austenitic stainless steel welding rod is carried out according to the following steps:

[0023] 1. Weigh marble, fluorite, cryolite, rutile, rare earth fluoride, alkali, atomized ferrosilicon, electrolytic manganese metal, nickel powder, and ferrotitanium according to the composition ratio of the low-nickel nitrogen-containing austenitic stainless steel electrode , metal chromium and iron powder, mixed to obtain a coating; of which marble 22wt.%, fluorite 6wt.%, cryolite 20wt.%, rutile 20wt.%, fluoride rare earth 2wt.%, alkali 1wt.%, atomization Ferrosilicon 1wt.%, electrolytic manganese metal 10wt.%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com