Nickel-saving austenitic stainless steel containing manganese, nitrogen and boron and fabrication method

A technology of austenitic stainless steel and manganese nitrogen boron, applied in the field of metal materials, can solve problems such as high cost, blisters, and easy to appear peeling, and achieve the effect of improving purity, good corrosion resistance, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

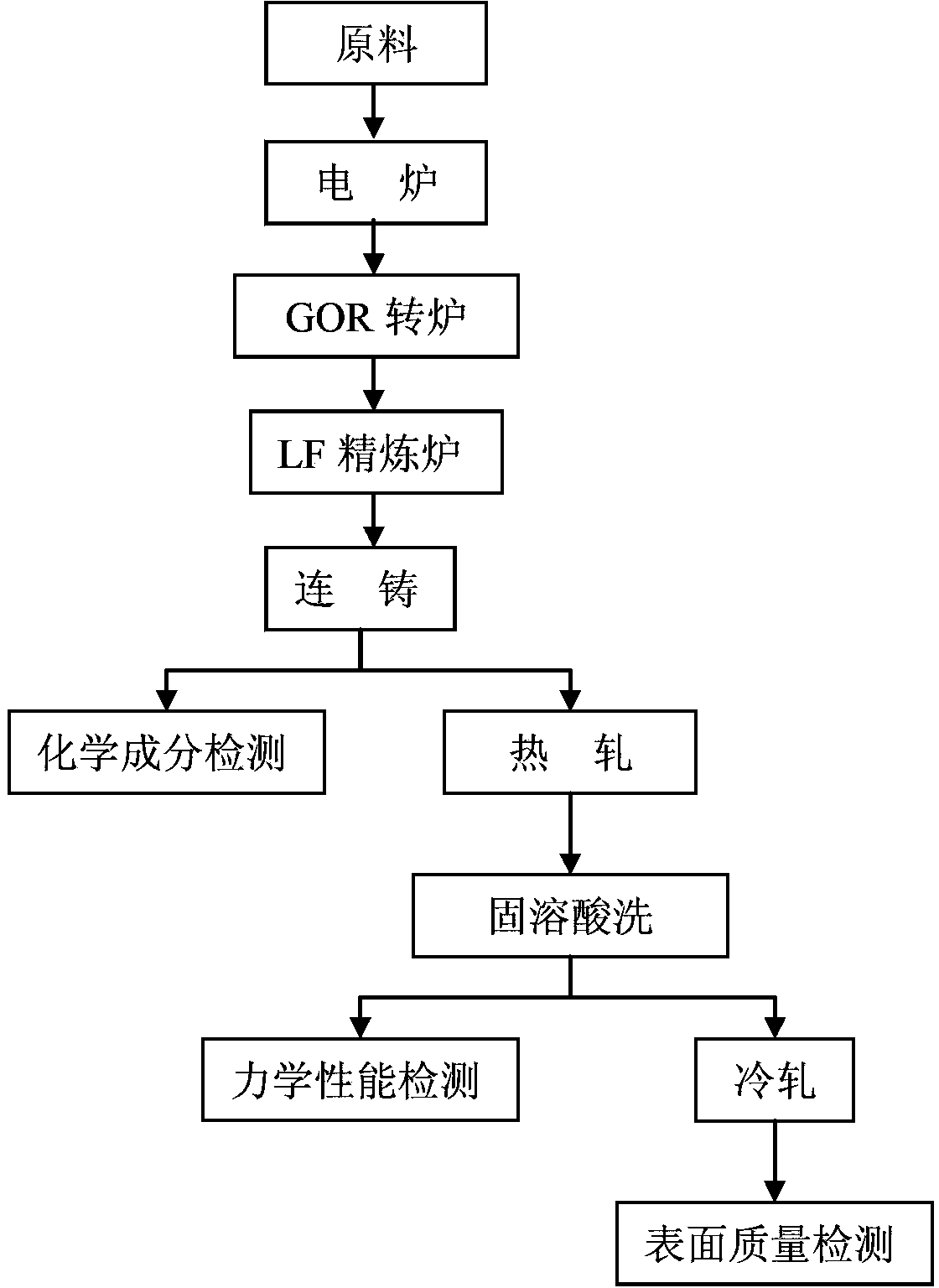

Method used

Image

Examples

Embodiment 1

[0035] 45t of nickel-containing pig iron (its main chemical composition by mass percentage is: C 4.4%, S 0.15%, P 0.052%, Si 0.80%, Ni1.72%, the balance is Fe) and high-carbon ferrochrome 20.3t (its The main chemical composition by mass percentage is: Cr60.5%, C4.5%, Si0.03%, P0.04%, S0.06%, and the balance is Fe) as the base material, which is added to the 70t electric arc furnace to melt the stainless steel mother liquor, The smelting time in the electric furnace was 122 minutes, and the tapping temperature was 1605°C. After all melting, it is transferred to GOR converter for decarburization, using ferrosilicon for reduction, using manganese alloy and electrolytic copper alloying, the quality of manganese alloy added is 86.5kg / t steel, electrolytic copper is 12.5kg / t steel, and the smelting time is 99min . The molten steel obtained at a temperature of 1552° C. has the following chemical composition by mass percentage: C0.085%, Si0.38%, Ni2.04%, Mn8.55%, N0.14%, and the bala...

Embodiment 2

[0050] 44t of nickel-containing pig iron (the main chemical composition by mass percentage is: C 4.38%, S 0.14%, P 0.048%, Si 0.76%, Ni1.71%, the balance is Fe) and high-carbon ferrochromium 20.8.t ( Its main components are: Cr61.8%, C4.7%, Si0.04%, P0.04%, S0.05%, and the balance is Fe) as the base material, which is added to the 70t electric arc furnace for smelting stainless steel mother liquor. The smelting time is 114min, and the tapping temperature is 1608°C. After all melting, it is transferred to GOR converter for decarburization, using ferrosilicon for reduction, using manganese alloy and electrolytic copper alloying, the quality of manganese alloy added is 95.1kg / t steel, electrolytic copper is 12.7kg / t steel, and the smelting time is 102min . A molten steel with a temperature of 1545°C is obtained. Its chemical composition by mass percentage is: C 0.075%, Si 0.41%, Ni 2.80%, Mn 9.4%, N 0.19%, and the balance is Fe.

[0051] The molten steel is then sent to LF for...

Embodiment 3

[0064] 43.5t of nickel-containing pig iron (the main chemical composition by mass percentage is: C 4.40%, S 0.13%, P 0.042%, Si0.79%, Ni1.69%, the balance is Fe) and high-carbon ferrochrome 21.8t (The main components are: Cr59.1%, C4.3%, Si 0.04%, P0.04%, S0.05%, and the balance is Fe) as the base material, which is added to the 70t electric arc furnace for smelting stainless steel mother liquor, and the electric furnace The smelting time is 98min, and the tapping temperature is 1611℃. After all melting, transfer to GOR converter for decarburization, use ferrosilicon to reduce, use manganese alloy and electrolytic copper alloying, the quality of manganese alloy added is 97.5kg / t steel, electrolytic copper is 17kg / t steel, and the smelting time is 100min. A molten steel with a temperature of 1642°C is obtained. Its chemical composition by mass percentage is: C 0.090%, Si 0.37%, Ni 2.50%, Mn 9.6%, N 0.16%, and the balance is Fe.

[0065] The molten steel is then sent to LF for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com