Method for recycling anaerobic fermentation liquor

An anaerobic fermentation liquid and recycling technology, which is applied in the field of anaerobic fermentation liquid recycling, can solve the problems of high cost of chemicals, and achieve the effects of increasing processing costs, improving resource utilization, and improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Taking the biogas slurry produced by anaerobic fermentation of livestock and poultry wastewater as an example, the NH in the biogas slurry 4 + Concentration 1000mg / L, PO 4 3- The concentration is 100mg / L, Mg 2+ The concentration is 171mg / L, Ca 2+ The concentration is 189mg / L.

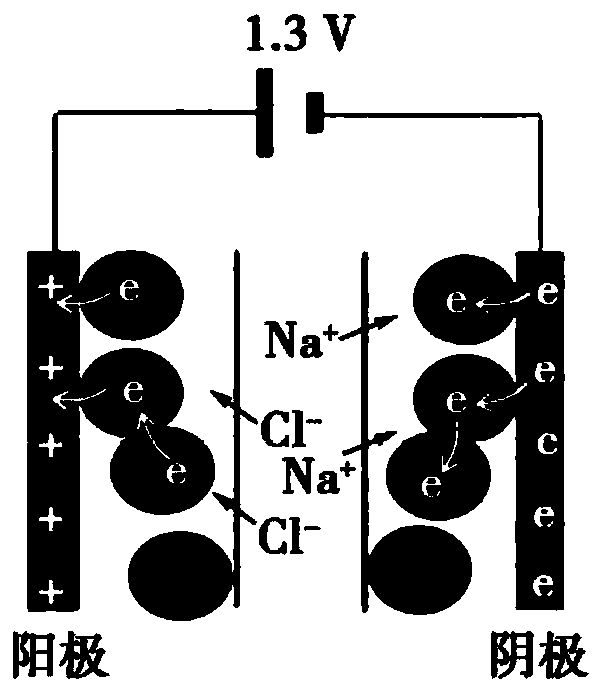

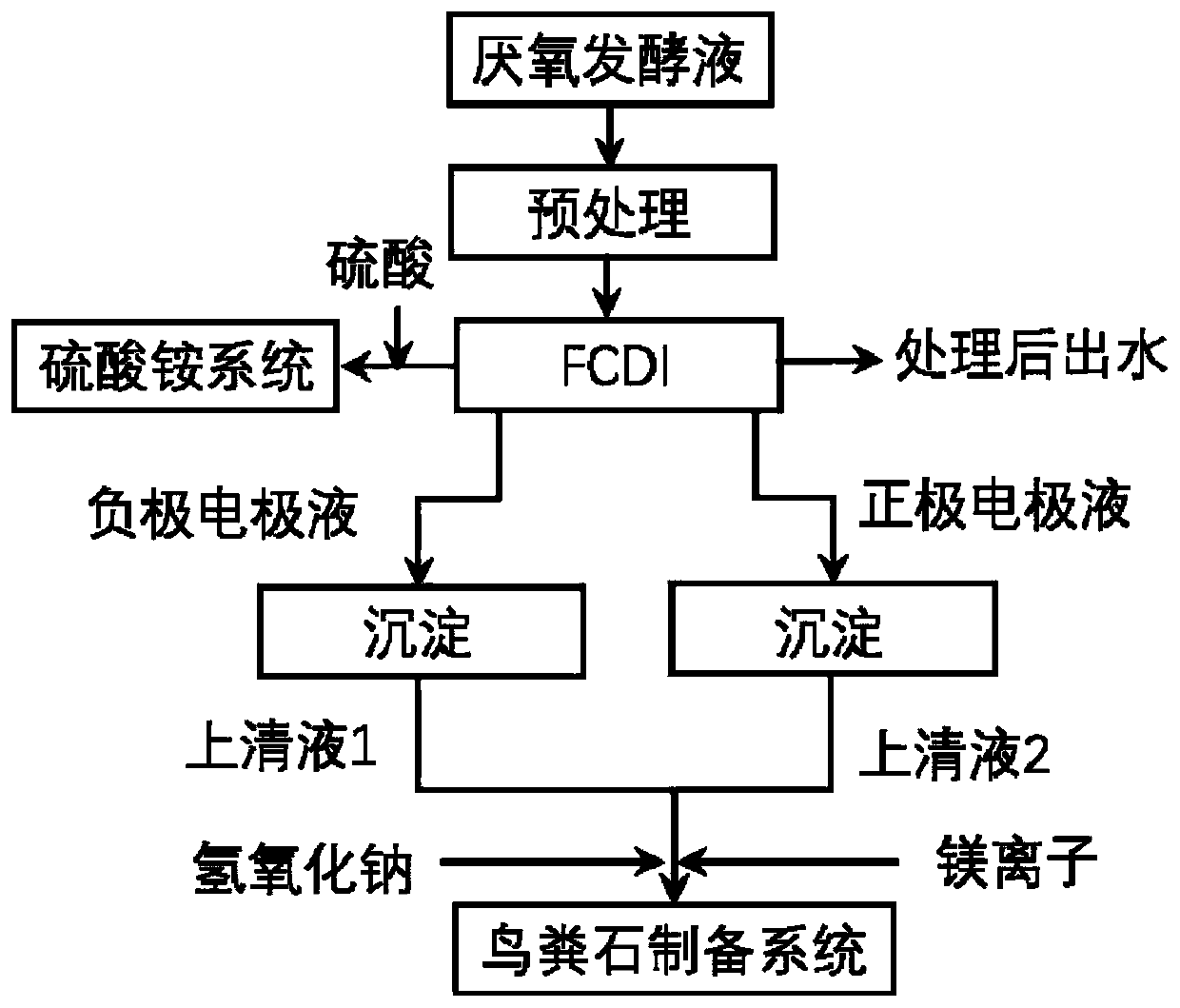

[0067] Add 1wt% activated sludge to the fermented liquid, first anaerobic treatment for 1h, then aeration treatment for 0.5h, the dissolved oxygen concentration is 0.5mg / L, and then pass through a multi-media filter (filter medium adopts quartz sand and anthracite) to remove particulate matter, Pump into FCDI module for desalination, select monovalent cation permselective membrane, and the current density of FCDI is 25A / m 2 , the hydraulic retention time is 8min, the mass fraction of activated carbon in the mobile electrode is 5%, the mass fraction of carbon black is 0.8%, the concentration of NaCl is 1mol / L, the contact angle of PTFE gaseous membrane is 120°, and the membrane pore size is 0...

Embodiment 2

[0070] Taking the biogas slurry produced by anaerobic fermentation of landfill leachate as an example, the NH in the biogas slurry 4 + Concentration 700mg / L, PO 4 3- The concentration is 40mg / L, Mg 2+ The concentration is 152mg / L, Ca 2+ The concentration is 167mg / L.

[0071] Add 3wt% activated sludge to the fermented liquid, first anaerobic treatment for 2h, then aeration treatment for 1h, the dissolved oxygen concentration is 3mg / L, and then remove particulate matter through a multi-media filter (filter medium adopts quartz sand and manganese sand), pump Into FCDI module for desalination, select monovalent cation permselective membrane, and the current density of FCDI is 13A / m 2 , the hydraulic retention time is 5min, the mass fraction of activated carbon in the flow electrode is 15%, the mass fraction of carbon black is 1.2%, the concentration of NaCl is 3mol / L, the contact angle of PTFE gaseous membrane is 130°, and the membrane pore size is 0.47μm , the porosity is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com