Method for epitaxial growth of high-quality and large-size monocrystalline diamond

A single crystal diamond, epitaxial growth technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of diamond layer adhesion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

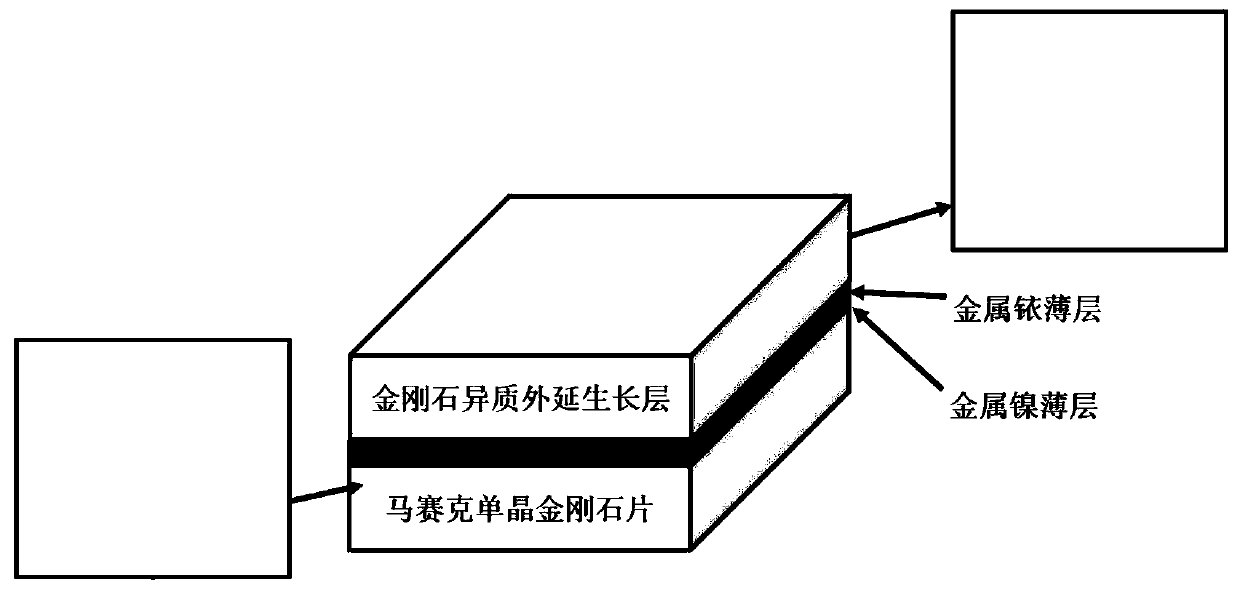

Embodiment 1

[0054] (1) Deposit a thin layer of metallic nickel by electron beam evaporation at a speed of 0.01nm / s under the condition of heating at 100°C on the ultra-flat mosaic single crystal diamond sheet after precision polishing and acid boiling cleaning pretreatment; (2) After the thickness of nickel thin layer deposition reaches 100nm, metal iridium is deposited at the same temperature, and metal iridium is deposited at a speed of 0.01nm / s to a thickness of 15nm at the initial stage of deposition; (3) after the initial stage of metal iridium deposition, increase the substrate heating Temperature to 700°C, continue to deposit metal iridium at a rate of 0.5nm / s to a thickness of 150nm; (4) Use a microwave plasma chemical vapor deposition system to control the input power to 1.5kW and the chamber pressure to 10kPa under the condition of pure hydrogen gas , the temperature is 700 ℃ to clean the surface of iridium for 10min, and then the methane with the flow rate of hydrogen is 10:100 ...

Embodiment 2

[0056] (1) Deposit a thin layer of metallic nickel by electron beam evaporation at a speed of 0.02nm / s under the condition of heating at 200°C on the ultra-flat mosaic single crystal diamond sheet after precision polishing and acid boiling cleaning pretreatment; (2) After the thickness of nickel thin layer deposition reaches 150nm, metal iridium is deposited at the same temperature, and metal iridium is deposited at a speed of 0.01nm / s to a thickness of 20nm in the initial stage of deposition; (3) after the initial stage of metal iridium deposition, increase the substrate heating Temperature to 800°C, continue to deposit metal iridium at a rate of 0.5nm / s to a thickness of 150nm; (4) Use a microwave plasma chemical vapor deposition system to control the input power to 1.5kW and the cavity pressure to 10kPa under the condition of pure hydrogen gas , the temperature is 700 ℃ to clean the surface of iridium for 20min, and then the methane with the hydrogen flow ratio of 12:100 is ...

Embodiment 3

[0058] (1) Deposit a thin layer of metallic nickel by electron beam evaporation at a speed of 0.03nm / s under the condition of heating at 300°C on the ultra-flat mosaic single crystal diamond sheet after precision polishing and acid boiling cleaning pretreatment; (2) After the thickness of nickel thin layer deposition reaches 150nm, metal iridium is deposited at the same temperature, and metal iridium is deposited at a speed of 0.01nm / s in the initial stage of deposition until the thickness reaches 30nm; (3) after the initial stage of metal iridium deposition, increase the substrate heating Temperature to 900°C, continue to deposit metal iridium at a rate of 0.5nm / s to a thickness of 200nm; (4) Use a microwave plasma chemical vapor deposition system to control the input power to 1.5kW and the cavity pressure to 10kPa under the condition of pure hydrogen gas , the temperature is 700 DEG C to clean the surface of iridium for 30min, and then feed methane with a flow ratio of 15:100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com