Phosphorus removal material based on collophanite tailings as well as preparation and application methods thereof

An application method and technology of collophosphate rock, applied in the field of phosphorus pollution control, can solve the problems of low phosphorus fixation efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

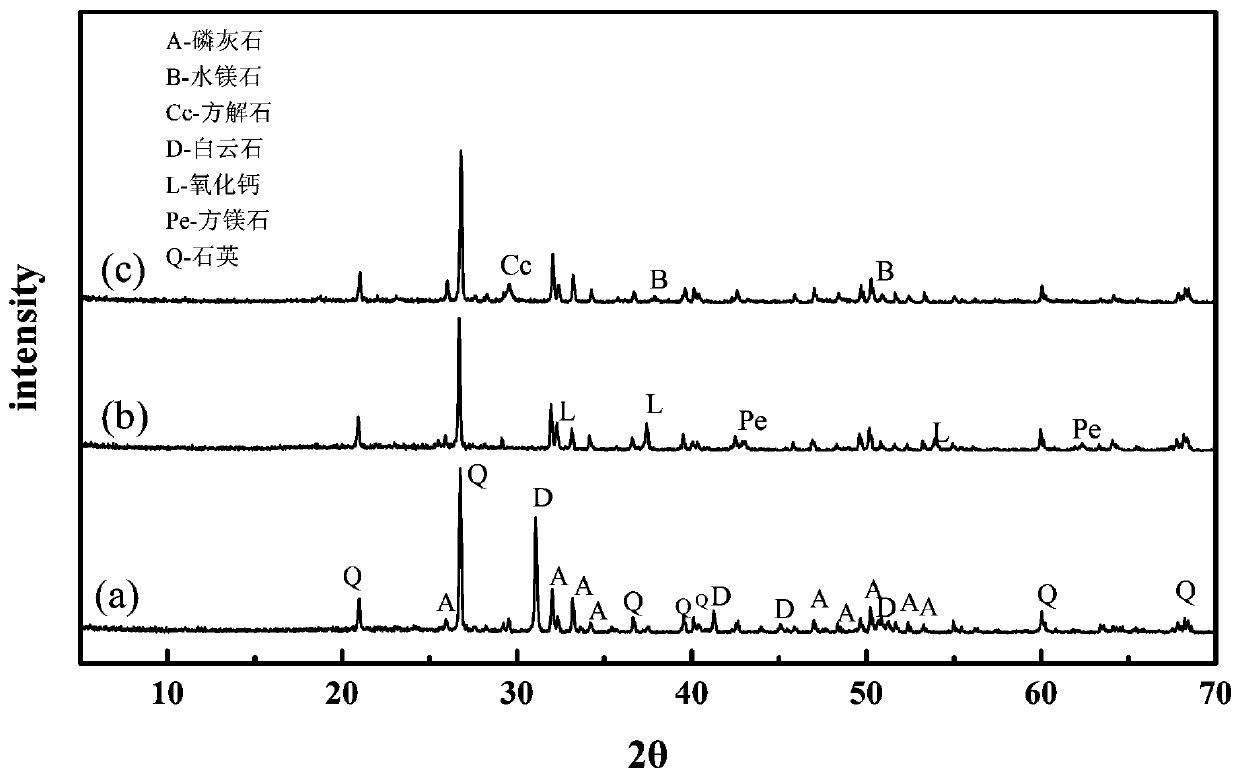

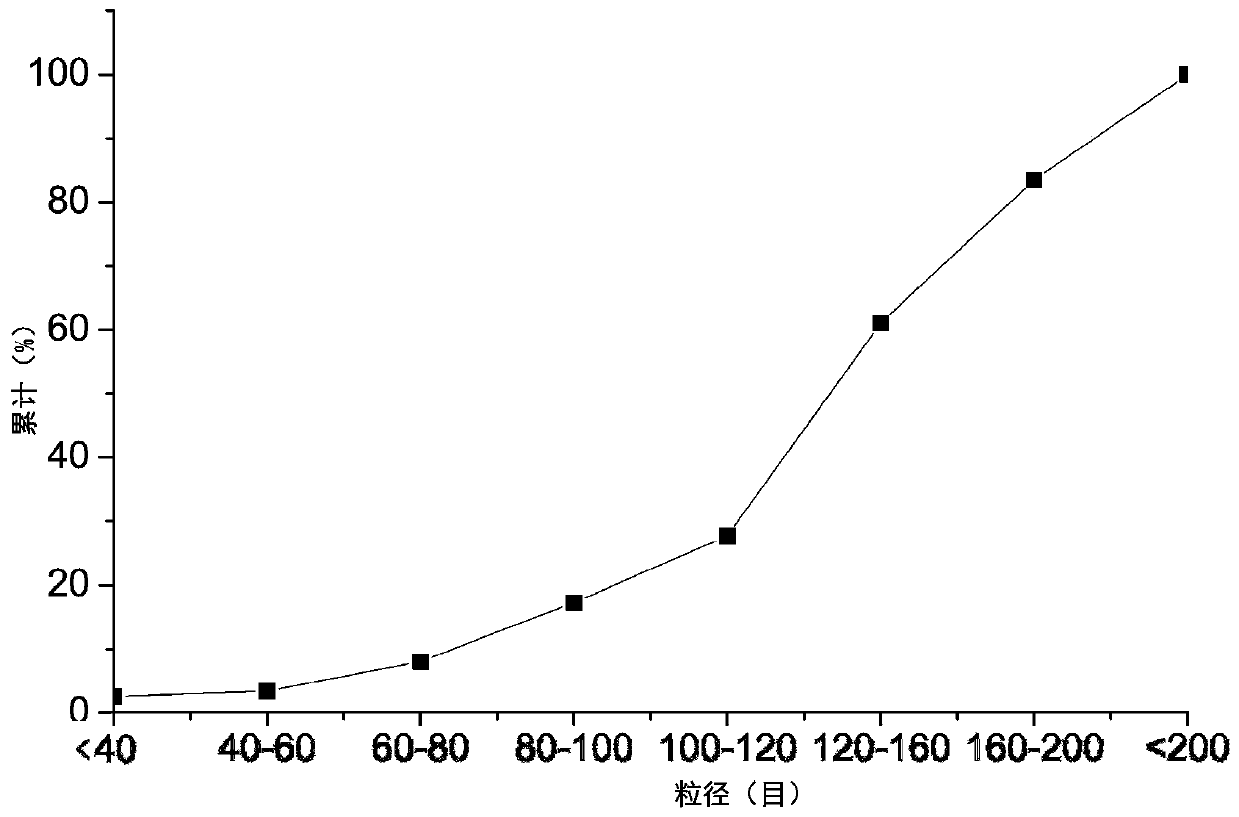

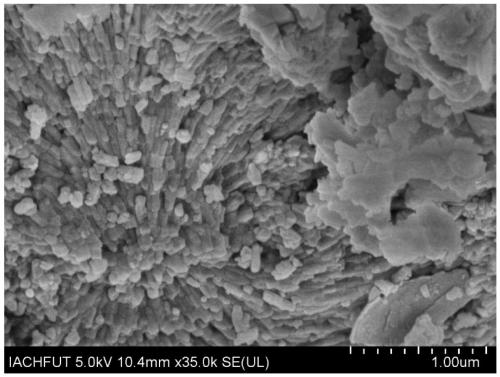

[0042] 200kg of representative collophanite tailings were collected from the tailings pond of the collophosite mine, and its XRD pattern is shown in figure 1 According to chemical phase analysis, its mineral composition is: apatite 31.2%, dolomite 26.3%, quartz 39.5%. figure 2 , where the morphology of apatite is shown in image 3 .

[0043] Put the collophanite tailings into a muffle furnace for calcination at 800°C for 1 hour, and the dolomite in it is completely decomposed into pericalcite (CaO) and periclase (MgO).

[0044] Add water accounting for 40% of the mass of the powder to the calcined powder, mix evenly, and shape it into rod-shaped particles of 3-5mm through an extrusion molding machine, store it for 20 days under saturated humidity and normal temperature conditions, and use 2 Carry out carbonation to convert calcium hydroxide into calcite, and partially hydrate magnesium oxide into magnesium hydroxide and achieve consolidation; the strength of the obtained pa...

Embodiment 2

[0047] This embodiment adopts the same collophantite tailings sand as in embodiment 1.

[0048] Put the collophanite tailings into a muffle furnace for calcination at 800°C for 1 hour, and the dolomite in it is completely decomposed into pericalcite (CaO) and periclase (MgO).

[0049] Add water accounting for 50% of the mass of the powder to the calcined powder, mix evenly, and then extrude it into a 5-10mm sheet, store it for 20 days under saturated humidity and normal temperature conditions, and use the CO in the air 2 Carry out carbonation to convert calcium hydroxide into calcite, and partially hydrate magnesium oxide into magnesium hydroxide and achieve consolidation; the resulting consolidated material is broken and sieved to particles with a particle size of 1-2mm, that is, the target product is obtained based on Phosphorus removal material for collophanite tailings.

[0050] Fill the prepared phosphorus removal material into a glass tube with a diameter of 10cm and a ...

Embodiment 3

[0052] This embodiment adopts the same collophantite tailings sand as in embodiment 1.

[0053] Pass the collophanite tailings sand and calcined dolomite powder (calcined at 800°C for 1 h in a muffle furnace) through a 60-mesh sieve, and mix them evenly according to the mass ratio of 1:1 to obtain a mixed material; add water to the mixed material and stir evenly to make the material Become moist, and shape into particles with a diameter of 5-10mm with a ball forming disc. The molded materials were stored for 20 days under the condition of saturated humidity and normal temperature, and the CO in the air was used to 2 Carry out carbonation to convert calcium hydroxide into calcite, and partially hydrate magnesium oxide into magnesium hydroxide and achieve consolidation; after stockpiling, the particle strength is 60N, that is, the target product is a phosphorus removal material based on collophosite tailings .

[0054] Fill the prepared phosphorus removal material into a glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com