Device based on elemental sulfur autotrophic denitrification process and wastewater treatment method

A technology of autotrophic denitrification and sulfur element, which is applied in special compound water treatment, polluted groundwater/leachate treatment, anaerobic digestion treatment, etc. Low abundance of oxidizing bacteria and other problems, to achieve the effects of stable properties, low power consumption, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

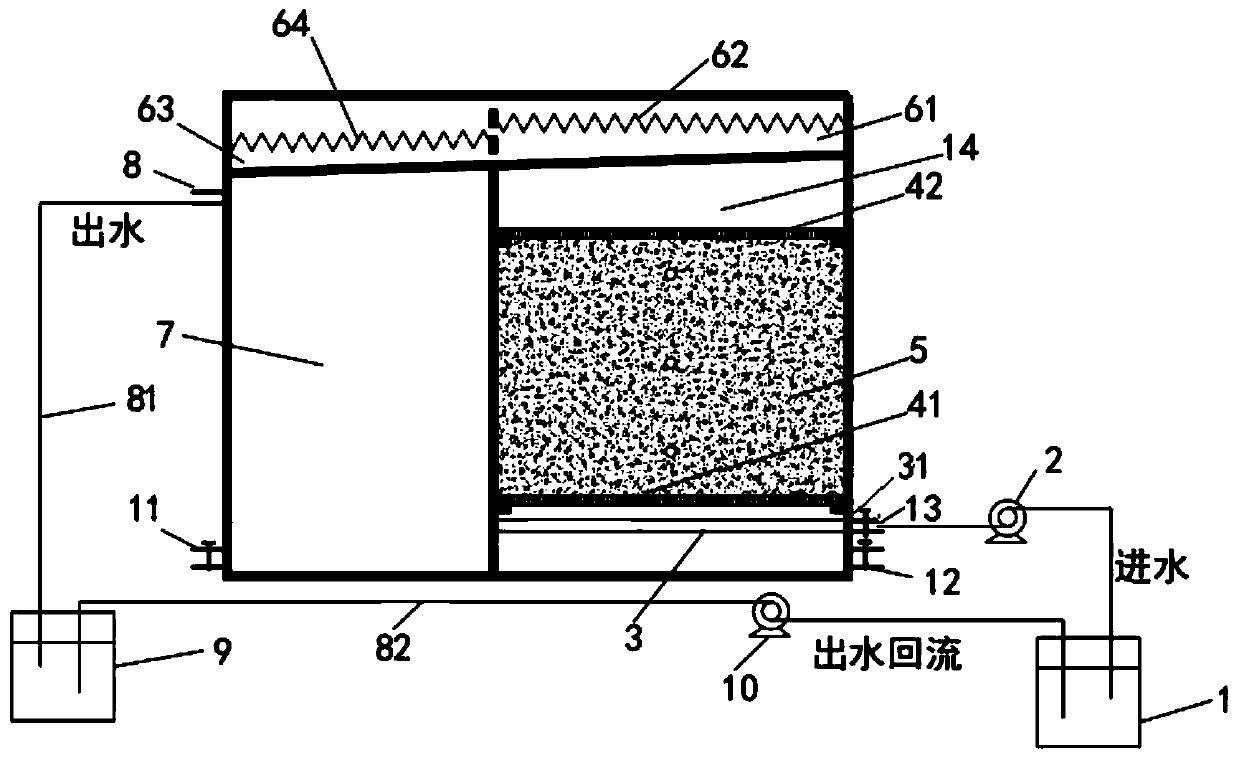

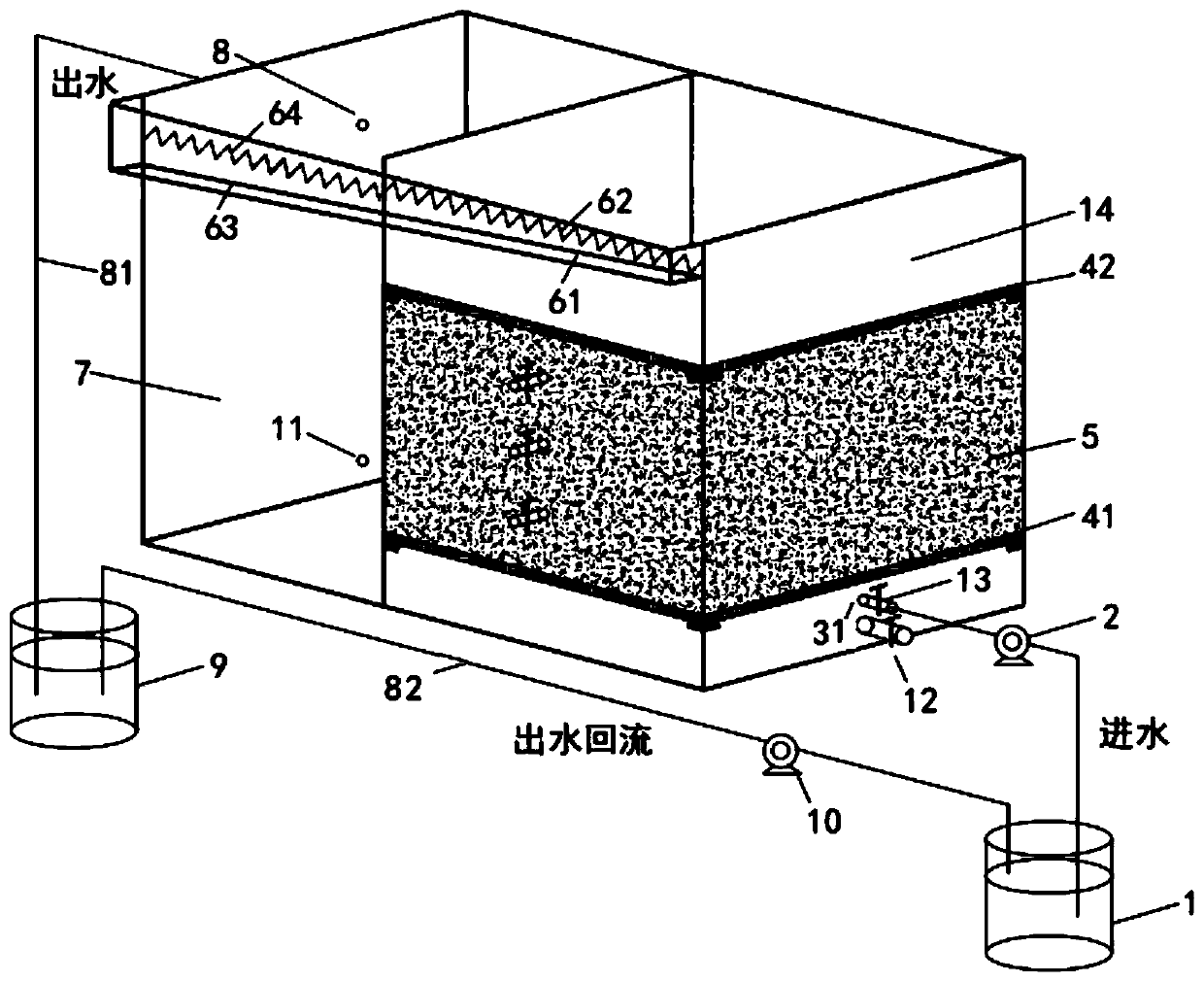

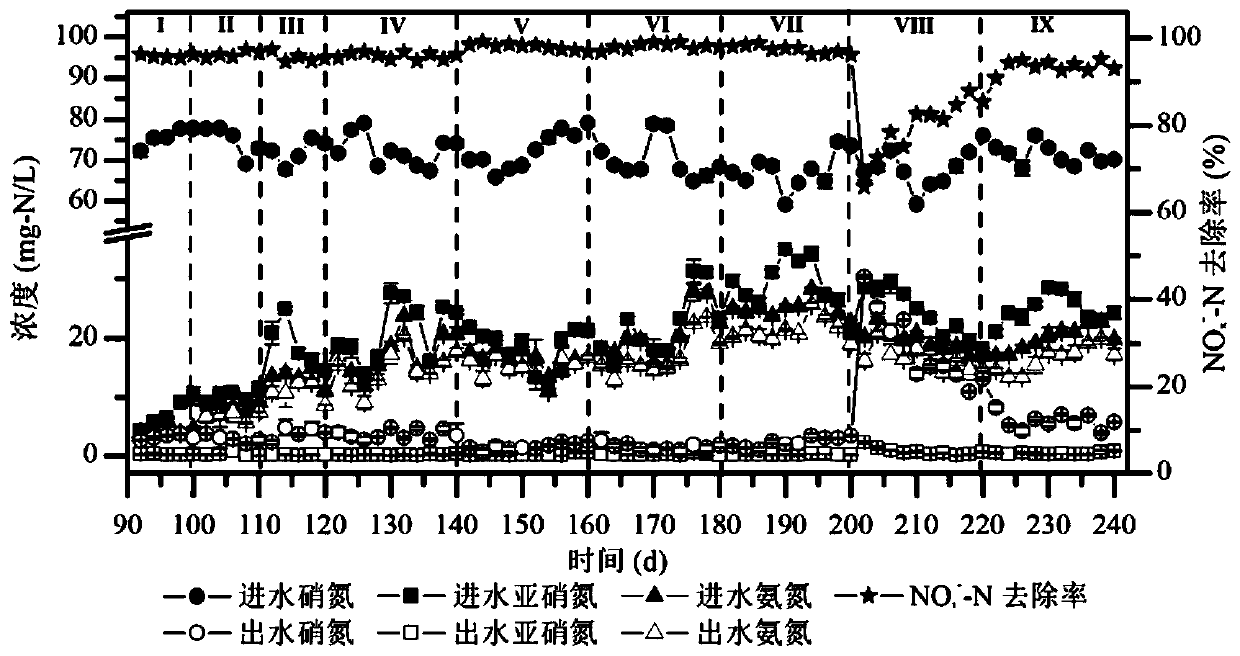

[0050] like figure 1 and figure 2 As shown, a device based on the sulfur elemental autotrophic denitrification process includes a sequentially connected water inlet system, a sulfur packed bed 5, a side overflow tank 6 and a sludge settling area 7; the water inlet system includes a water inlet valve 13. Water inlet barrel 1, water inlet pump 2, water inlet pipe 3 and water inlet 31, the first screen 41 is set on the sulfur packed bed 5 to support the sulfur sheets, and the second screen 42 is set on the sulfur packed bed 5 for By intercepting the sulfur flakes, the effluent from the sulfur packed bed 5 overflows to the first side overflow tank 61 and the second side overflow tank 63 and then overflows to the sludge settling area 7 behind the reactor, the first sawtooth weir 62 and The second sawtooth weir 64 is used to filter part of the suspended sludge. The sludge settling area 7 is provided with a second sludge discharge port 11 and an overflow water outlet 8. The water o...

Embodiment 2

[0066] In the embodiment of the present invention, before step S1, sludge domestication is carried out by continuously feeding artificially synthesized wastewater.

[0067] The sulfur flakes were washed, dried and weighed, and their density was calculated by the drainage method. The porosity of the sulfur packed bed is set to 50%, the sulfur flakes are put into the sulfur packed bed to make the occupied volume 3L, and the mass of the put sulfur flakes is 3L×sulfur density. The 3L sludge concentration is 5g / L (in terms of mixed liquid suspended solids) laboratory domesticated sulfur autotrophic denitrification sludge sludge water mixture with sulfide as the electron donor is evenly dosed into the reactor from the upper part of the reactor, The inoculation was repeated for 2 days, and the water was not used at this stage. The purpose was to increase the contact between the sludge and the sulfur sheet, and facilitate the microorganisms to form a film on the sulfur sheet.

[0068...

Embodiment 3

[0074] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 5 As shown, the reaction zone is divided into a first reaction zone and a second reaction zone, and the left and right zones have the same length, width and height, and are placed in parallel. The length, width and height of the first reaction zone and the second reaction zone are respectively set to 20cm, 20cm and 25cm, so the length, width and height of the reaction zone are 20cm, 40cm and 25cm. The left and right areas treat wastewater independently, increasing the amount of water treated per unit time and saving time for wastewater treatment. The length, width, and height of the sludge sedimentation area 7 are 15cm, 40cm, and 25cm respectively. Among them, the middle part of the rear facade of the sludge sedimentation area 7 has a mud discharge port at a height of 1 cm and an overflow outlet at 21 cm. The effective volume is 12.6L.

[0075] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com