Preparation method of ethyl glucuronide and ethyl sulfate of ethyl alcohol non-oxidative metabolite

A technology of glucuronide and ethyl sulfate, which is applied in the field of compound preparation, can solve the problems of lack of purification methods, low yield and purity, etc., and achieve the effects of easy implementation, simple operation, and low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

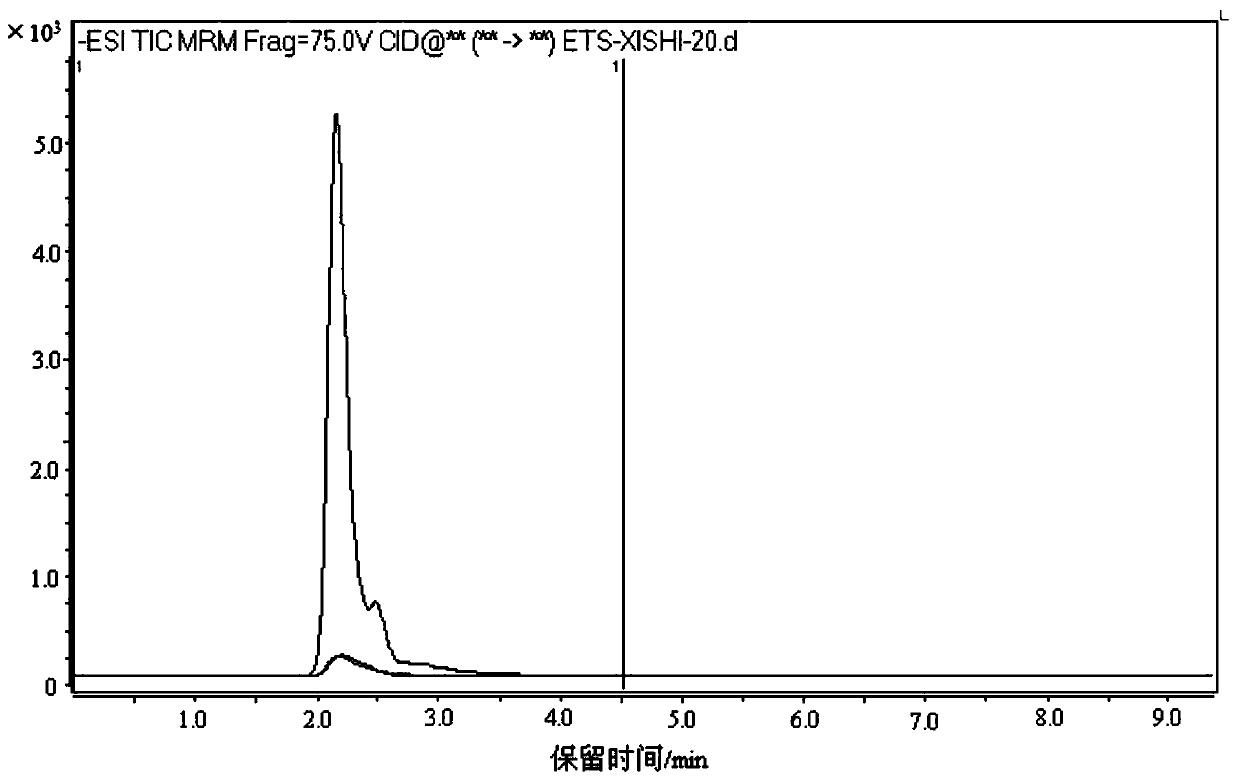

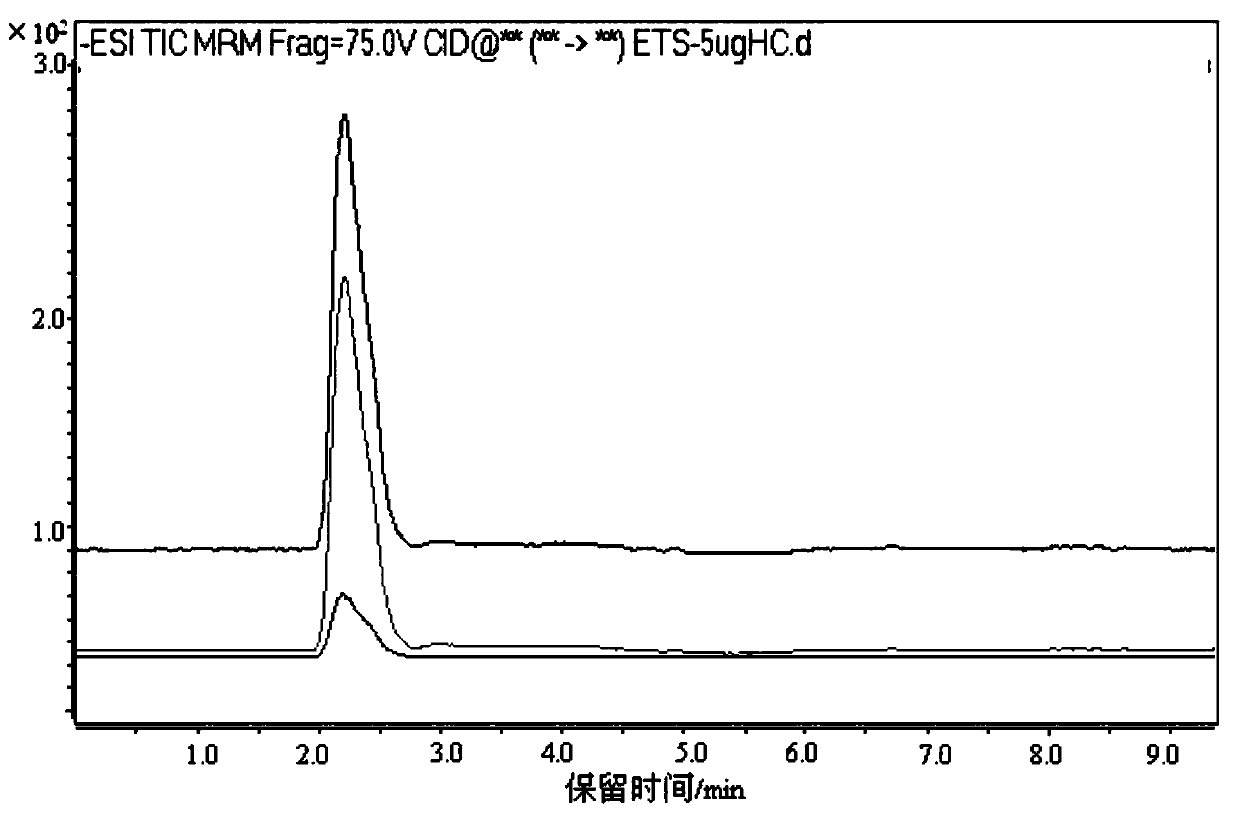

Image

Examples

Embodiment 1

[0038] Synthetic ethanol non-oxidative metabolite ethyl glucuronide, its preparation method is as follows:

[0039](1) Raw materials for the synthesis of triacetylbromoglucuronide methyl ester (BGAME): mix 16.7g glucuronolactone with 200ml methanol (containing 0.3g sodium methoxide), sonicate until completely dissolved, let stand for 30min, 40 ℃ water bath to dry; then add 68ml of acetic anhydride to completely dissolve, then add 10ml of acetic anhydride (containing 0.3ml of perchloric acid) drop by drop, control the temperature during the dropwise addition not to exceed 40°C, overnight at room temperature; add 0.1ml of perchloric acid After mixing evenly, precipitate crystals overnight in a refrigerator at -20°C. After filtration, take the solid part, rinse it with ether until it is milky white, dry it, and put it in a beaker. Use hot ethanol to recrystallize to obtain triacetylbromoglucose Raw material of methyl alkydate (BGAME).

[0040] (2) Synthesis of methyl triacetylbr...

Embodiment 2

[0045] Synthetic ethanol non-oxidative metabolite ethyl glucuronide, its preparation method is as follows:

[0046] (1) Raw materials for the synthesis of triacetylbromoglucuronide methyl ester (BGAME): mix 15.0g glucuronolactone with 250ml methanol (containing 0.2g sodium methoxide), sonicate until completely dissolved, let stand, 40°C Evaporate to dryness in a water bath; add acetic anhydride to dissolve it, add 12ml of acetic anhydride solution dropwise (wherein the acetic anhydride solution contains 3% perchloric acid by volume), overnight at room temperature; then add 0.1ml of perchloric acid After mixing evenly, put it in the refrigerator at -20°C overnight until the crystals are precipitated; after filtering, take the solid part, rinse it with ether to milky white, and dry it to obtain the raw material of triacetyl bromoglucuronide methyl ester (BGAME).

[0047] (2) Synthesis of methyl triacetylbromoglucuronate (BGAME): After mixing 5 g of the BGAME raw material prepare...

Embodiment 3

[0050] Synthetic ethanol non-oxidative metabolite ethyl glucuronide, its preparation method is as follows:

[0051] (1) Raw materials for the synthesis of triacetylbromoglucuronide methyl ester (BGAME): mix 18.0g glucuronolactone with 150ml methanol (containing 0.5g sodium methoxide), sonicate until completely dissolved, let it stand at 40°C Add acetic anhydride to make it dissolve again, dropwise add 12ml of acetic anhydride solution containing perchloric acid (wherein the volume percentage of perchloric acid is 3%), ensure that the temperature of the reaction system in the dropping process is not higher than 40°C overnight at room temperature; then add 0.1ml of perchloric acid, mix well and place in a refrigerator at -20°C overnight until crystals are precipitated; after filtering, take the solid part, wash it with ether until milky white, and dry it to get Raw material of triacetylbromoglucuronide methyl ester (BGAME).

[0052] (2) Synthesis of methyl triacetylbromoglucuro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com