A kind of seawater desalination micro-nano membrane material, its preparation method and application

A membrane material, micro-nano technology, applied in the field of membrane material technology and seawater desalination, can solve problems such as restricting the development of seawater desalination membrane materials, secondary water pollution, and complicated preparation process, and achieve good large-scale preparation application prospects and low prices. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

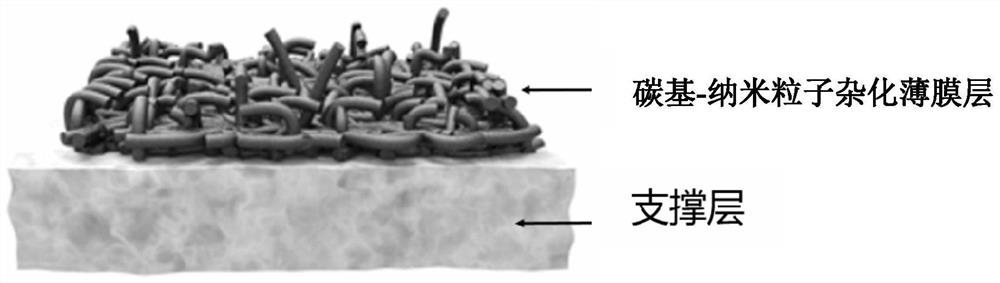

[0058] As another aspect of the technical solution of the present invention, it also relates to a preparation method of seawater desalination micro-nano membrane material, which includes:

[0059] Dispersing the carbon-based material in the first liquid phase system to form a carbon-based material dispersion;

[0060] Transferring the carbon-based material dispersion to the liquid surface of the second liquid phase system, followed by capillary extrusion to form a carbon-based material film layer;

[0061] Transferring the carbon-based material thin film layer to a nanoparticle solution system, and performing evaporation deposition, so that a plurality of nanoparticles are deposited on the carbon-based material thin film layer to form a carbon-nanoparticle hybrid thin film layer;

[0062] And, using a top-down capillary force assisted interface transfer method to transfer the carbon-nanoparticle hybrid film layer to the surface of the support layer, so as to obtain the seawate...

Embodiment 1

[0079] 1. Aminated carbon nanotubes with a volume of 10ml and a mass ratio of 0.5:2 (amino ratio 1%, carbon nanotube length 100nm) and hydroxylated graphene oxide (hydroxyl ratio 1.5%, the size of graphene is 300nm ) into 100ml of ethanol solution, and ultrasonically disperse for 2h to obtain a uniformly dispersed carbon-based material dispersion of 0.1mg / ml;

[0080] 2. Transfer the carbon-based material dispersion obtained in step 1 to the water surface by spraying and subsequent peristaltic injection. In order to ensure the uniformity of the film material, the spraying rate is 25mL / min, and peristaltic injection is performed after 1min. The injection rate is 1mL / min, and finally pump out the excess ethanol as soon as possible, the pumping rate is 1mL / min;

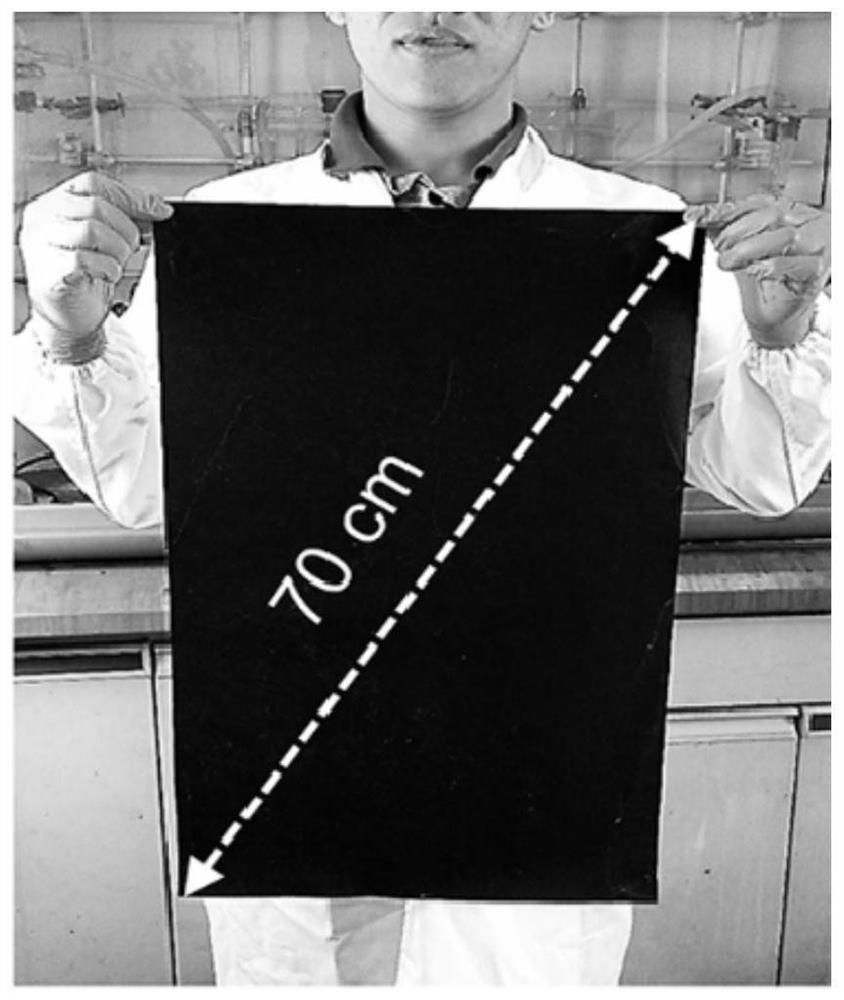

[0081] 3. Extrude the loose film obtained in the solution step 2 by capillary extrusion to form a layer of uniform, dense, stable and orderly carbon-based material film. The size of the capillary force affects the compac...

Embodiment 2

[0087] 1. Carboxylated carbon nanotubes with a volume of 20ml and a mass ratio of 1:2 (carboxyl ratio 1.5%, carbon nanotube length 500nm) and carboxylated graphene oxide (hydroxyl ratio 1%, graphene size 1μm ) into 200ml of ethanol solution, and ultrasonically disperse for 2h to obtain a uniformly dispersed carbon-based material dispersion with a concentration of 0.5mg / ml;

[0088] 2. Transfer the carbon-based material dispersion obtained in step 1 to the water surface by spraying and subsequent peristaltic injection. In order to ensure the uniformity of the film material, the spraying rate is 35mL / min, and peristaltic injection is performed after 1min. The injection rate is 4mL / min, and finally pumped to get rid of excess ethanol as soon as possible, the pumping rate is 3mL / min;

[0089] 3. Extrude the loose film obtained in the solution step 2 by capillary extrusion to form a layer of uniform, dense, stable and orderly carbon-based material film. The size of the capillary fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com