Protection method of alkali metal negative electrode, negative electrode prepared thereby and application

An alkali metal and alkali metal battery technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of uneven metal deposition, dendrite growth, etc., achieve excellent structural integrity, reduce structural collapse and powder the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

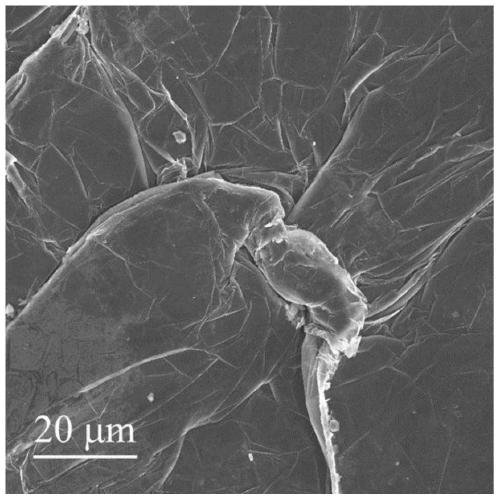

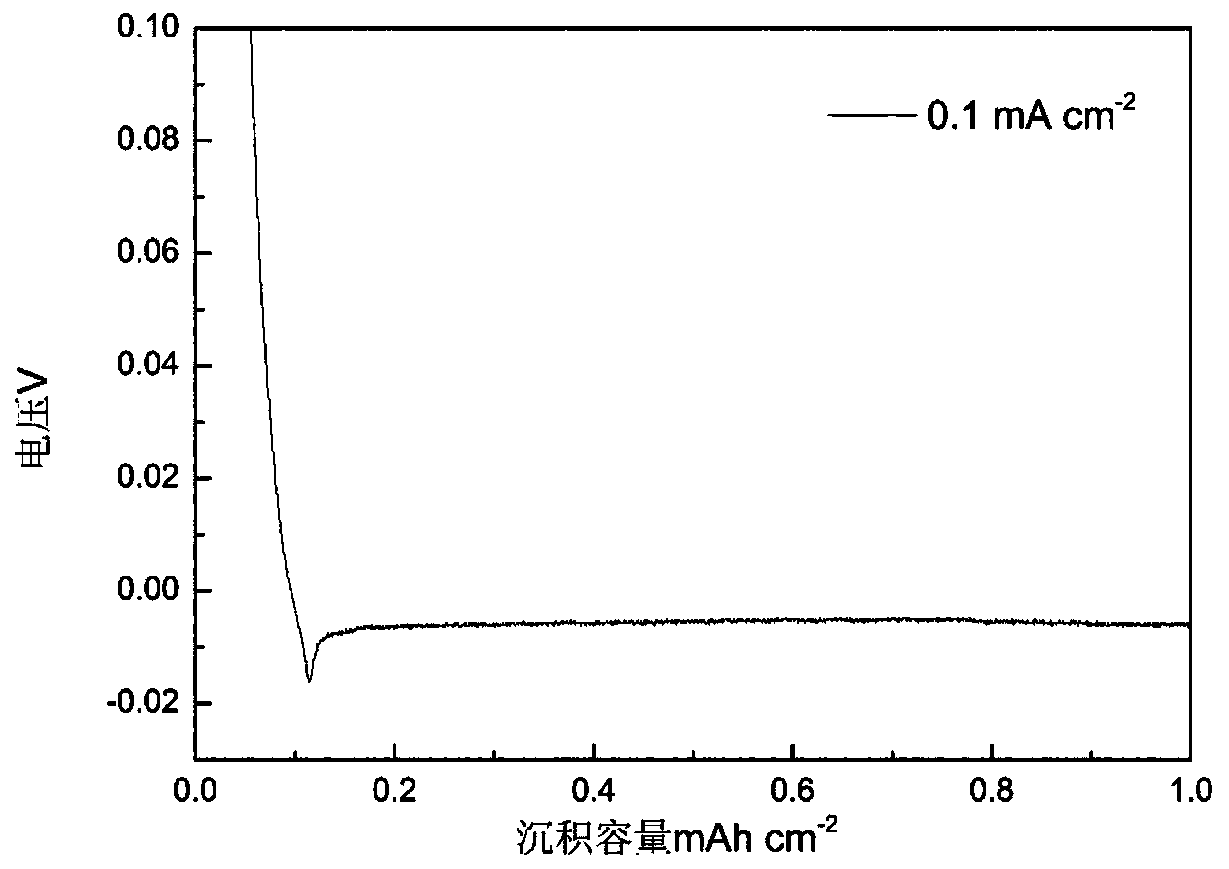

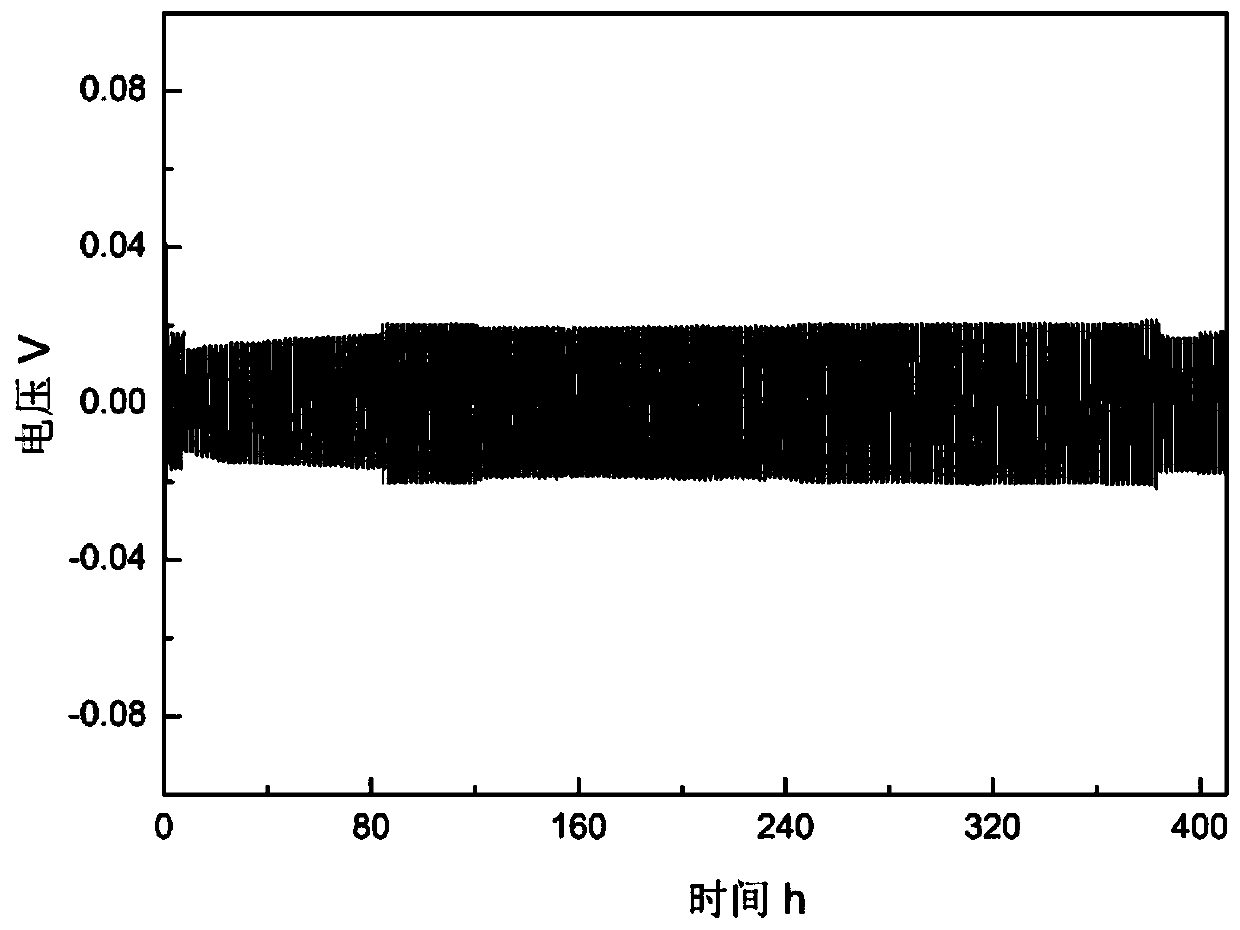

Embodiment 1

[0058] A mixture obtained by mixing polymer polyimide with graphene after carbonization at 800°C for 2 hours was selected, and then pressed into a film in a hot roller press to obtain a thermally conductive carbon film. The film-forming pressure was 8MPa, and the roller The pressing speed is 0.5 m / min, and the temperature is 400°C. The obtained thermally conductive carbon film was cut into discs with a diameter of 15 mm. The graphene content in the thermally conductive carbon film is 20%, the porosity is 5%, and the thickness is 50 μm. Using metal lithium as the working electrode and copper foil as the counter electrode, add and stack on the surface of metal lithium and cover the surface of metal lithium sheet. (The following cases, unless otherwise stated, the setting of the protective layer is the same as this case) The thermal conductive carbon film is used as the protective layer, with 1M LiTFSI+DOL-DME+2%LiNO 3 The electrolyte is assembled into a button half cell and a ...

Embodiment 2

[0060] Compared with Example 1, the difference is that the content of graphene is changed, specifically:

[0061] A mixture obtained by mixing polymer polyimide with graphene after carbonization at 800°C for 2 hours was selected, and then pressed into a film in a hot roller press to obtain a thermally conductive carbon film. The film-forming pressure was 8MPa, and the roller The pressing speed is 0.5 m / min, and the temperature is 400°C. The obtained thermally conductive carbon film was cut into discs with a diameter of 15 mm. The graphene content in the thermally conductive carbon film is 25%, the porosity is 7%, and the thickness is 50 μm. Use metal lithium as the working electrode, copper foil as the counter electrode, add the thermally conductive carbon film on the surface of metal lithium as a protective layer, and use 1M LiTFSI+DOL-DME+2%LiNO 3 The electrolyte is assembled into a button half cell and a button symmetrical cell. at 0.1mA / cm 2 current density and 1mAh / cm...

Embodiment 3

[0063] Compared with Example 1, the difference is that the film-forming pressure is changed, specifically:

[0064] A mixture obtained by mixing polymer polyimide with graphene after carbonization at 800°C for 2 hours was selected, and then pressed into a film in a hot roller press to obtain a thermally conductive carbon film. The film-forming pressure was 6MPa, and the roller The pressing speed is 0.5 m / min, and the temperature is 400°C. The obtained thermally conductive carbon film was cut into discs with a diameter of 15 mm. The graphene content in the thermally conductive carbon film is 20%, the porosity is 9%, and the thickness is 70 μm. Use metal lithium as the working electrode, copper foil as the counter electrode, add the thermally conductive carbon film on the surface of metal lithium as a protective layer, and use 1M LiTFSI+DOL-DME+2%LiNO 3 The electrolyte is assembled into a button half cell and a button symmetrical cell. at 0.1mA / cm 2 current density and 1mAh / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com