High-plasticity degradable LiZn4-X intermetallic compound and preparing method thereof

An intermetallic compound, lizn4-x technology, applied in the field of design and preparation of biodegradable medical materials, can solve the problems of prolonging the recovery period, aggravating the economic and psychological burden of patients, and achieving the promotion of precipitation and recrystallization, and enhanced plasticity , good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: LiZn 4 - Preparation and performance testing of intermetallic compounds.

[0036] The biodegradable LiZn 4 The mass percentage of each chemical element in the -X intermetallic compound is shown in Table 1-1, and the balance is β-LiZn 4 . The preparation process of the intermetallic compound is high temperature homogenization treatment→rolling or extrusion→low temperature aging.

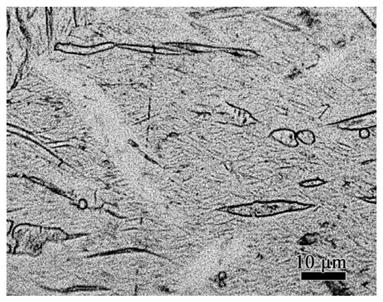

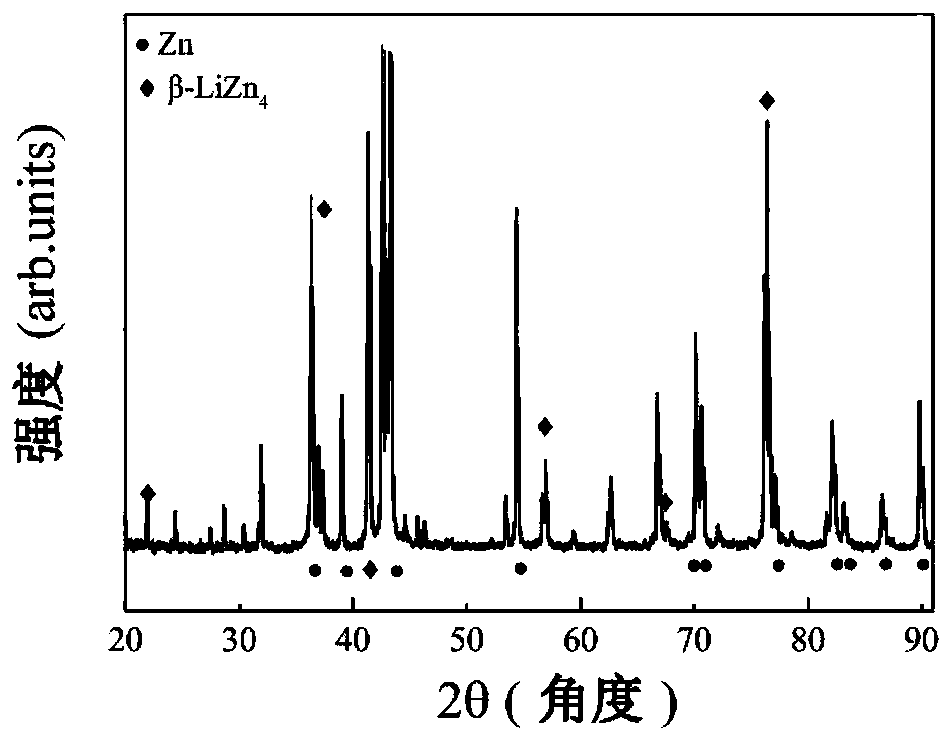

[0037] Homogenization treatment: place the intermetallic compound ingot in a box-type heating and sintering furnace KSL-1400X, raise the temperature to 250°C at a rate of 10°C / min, and keep it for 2 hours; then raise the temperature to 350°C at a rate of 1°C / min ℃, keep warm for 2 hours and then quench in water at room temperature. Obtain the microstructure multi-level structure metallographic photograph of invention example intermetallic compound 1 as figure 1 As shown, the intermetallic compound is composed of coarse grains, and the intragranular is Zn+β-LiZn 4 Lamellar struc...

Embodiment 2

[0051] Example 2: LiZn 4 -X 1 -X 2 Preparation and property testing of intermetallic compounds.

[0052] The biodegradable LiZn 4 -X 1 -X 2 The mass percentage of each chemical element in the intermetallic compound is shown in Table 2-1, and the balance is β-LiZn 4 . The preparation process of the intermetallic compound is high temperature homogenization treatment→extrusion or rolling→low temperature aging treatment. Melting, homogenization heat treatment, extrusion, rolling and aging treatment are carried out according to the method provided in Example 1. Modified LiZn 4 -X 1 -X 2 The microstructure of intermetallic compounds after low-temperature aging is composed of grains with a size of 5-30 μm, and the grains are composed of Zn+β-LiZn 4 It is composed of lamellar structure, and the distance between the lamellar layers is 0.3-0.7 μm. In addition, nano-scale / micro-scale precipitated phases formed by added elements are also precipitated at the intragranular and gra...

Embodiment 3

[0059] Example 3: LiZn 4 -X 1 -X 2 -X 3 Preparation and property testing of intermetallic compounds.

[0060] The biodegradable LiZn 4 -X 1 -X 2 -X 3 The mass percentage of each chemical element in the intermetallic compound is shown in Table 3-1, and the balance is β-LiZn 4 . The preparation process of the intermetallic compound is high temperature homogenization treatment→extrusion or rolling→low temperature aging treatment. Melting, homogenization heat treatment, extrusion, rolling and aging treatment are carried out according to the method provided in Example 1. Modified LiZn 4 -X 1 -X 2 -X 3 The microstructure of the intermetallic compound after homogenization heat treatment is composed of grains with a size of 5-30 μm, and the grain is composed of Zn+β-LiZn 4 It is composed of lamellar structure, and the spacing of the lamellar layers is 0.2-0.4 μm. In addition, nano-scale / micro-scale precipitated phases formed by added elements are also precipitated at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com