Polyurethane elastic cross-linking agent, high-strength and high-toughness vegetable protein adhesive and application

A technology of polyurethane elasticity and vegetable protein, which is applied in the field of polyurethane elastic cross-linking agent and high-strength vegetable protein adhesive, which can solve the obstacles to the development and promotion of vegetable protein-based adhesives, the lack of energy dissipation ability and the impact resistance of the adhesive layer , unfavorable improvement of adhesive properties and other issues, to achieve the effect of eliminating the release of harmful substances, excellent compatibility, and solving the dependence on fossil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

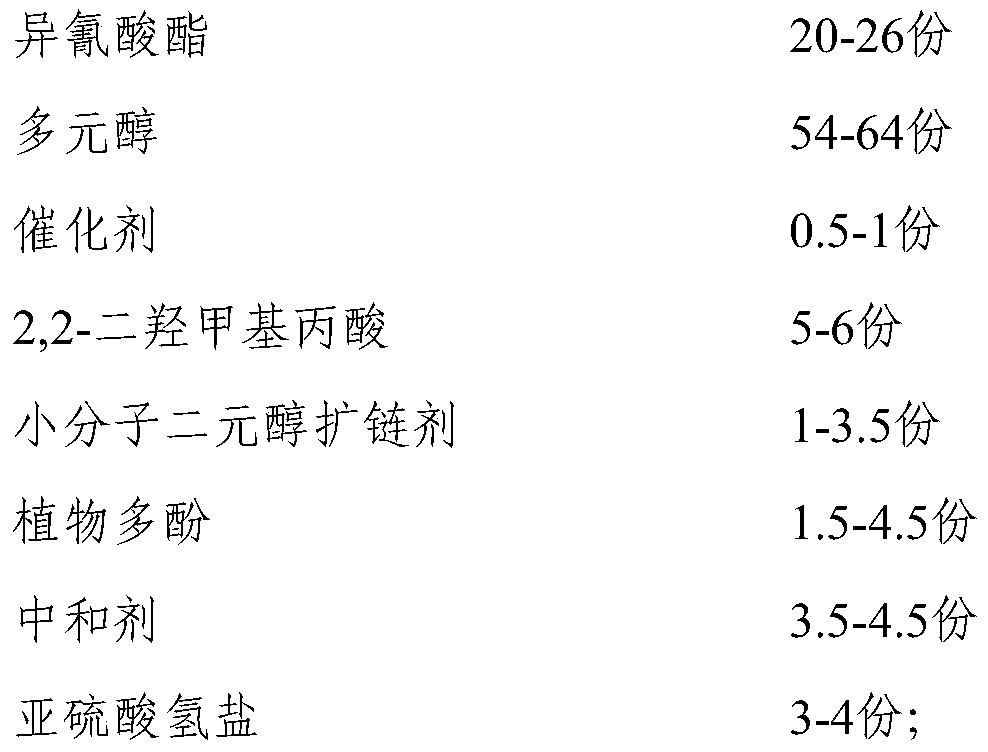

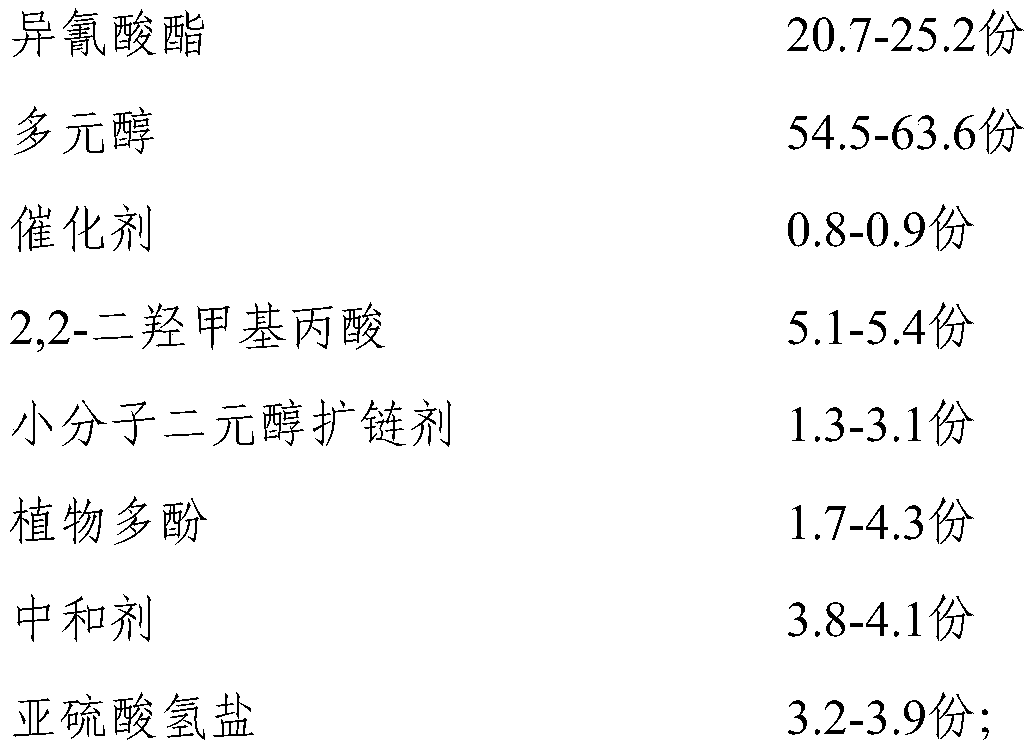

Method used

Image

Examples

Embodiment 1

[0079] A high-strength vegetable protein adhesive, which is made of the following components: 75kg of softened water, 25kg of vegetable protein meal, 6kg of polyurethane elastic crosslinking agent, and 2.5kg of curing agent.

[0080] The high-strength vegetable protein adhesive of this embodiment can be used to prepare wood-based panels.

[0081] This embodiment also provides a preparation method of the high-strength vegetable protein adhesive, which includes the following steps:

[0082] S1 In a reactor equipped with a stirrer, add demineralized water and vegetable protein meal according to the ratio and stir evenly;

[0083] S2 is added with polyurethane elastic cross-linking agent according to the ratio and stirred evenly to prepare vegetable protein mucus;

[0084] S3 is prepared by adding curing agent according to the proportion and performing homogenizer treatment, and the pressure of homogenization treatment is 25MPa.

[0085] Three batches of parallel samples were prepared with t...

Embodiment 2

[0087] A high-strength vegetable protein adhesive, which is made of the following ingredients: 70kg of softened water, 30kg of vegetable protein meal, 7kg of polyurethane elastic crosslinking agent, and 3kg of curing agent.

[0088] The high-strength vegetable protein adhesive of this embodiment can be used to prepare wood-based panels.

[0089] The preparation method of the high-strength vegetable protein adhesive in this example is basically the same as that of Example 1.

[0090] Three batches of parallel samples were prepared in the same way, and the performance and quality indexes of the prepared adhesives are shown in Table 1.

Embodiment 3

[0092] A high-strength vegetable protein adhesive, which is made of the following components: 65 kg of softened water, 35 kg of vegetable protein meal, 6 kg of polyurethane elastic crosslinking agent, and 3.5 kg of curing agent.

[0093] The high-strength vegetable protein adhesive of this embodiment can be used to prepare wood-based panels.

[0094] The preparation method of the high-strength vegetable protein adhesive in this example is basically the same as that of Example 1.

[0095] Three batches of parallel samples were prepared in the same way, and the performance and quality indexes of the prepared adhesives are shown in Table 1.

[0096] Table 1 Performance Index of Adhesive

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com