Polypropylene glass fiber material with good appearance and low warpage, and preparation method thereof

A technology of polypropylene and low warpage, applied in the field of polymers, which can solve the problems of high molding shrinkage rate, reduced shrinkage rate, difficulty in consistent distribution of glass fibers, etc., to achieve enhanced interface interaction, good surface and low warpage , Improve the effect of shrinkage uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

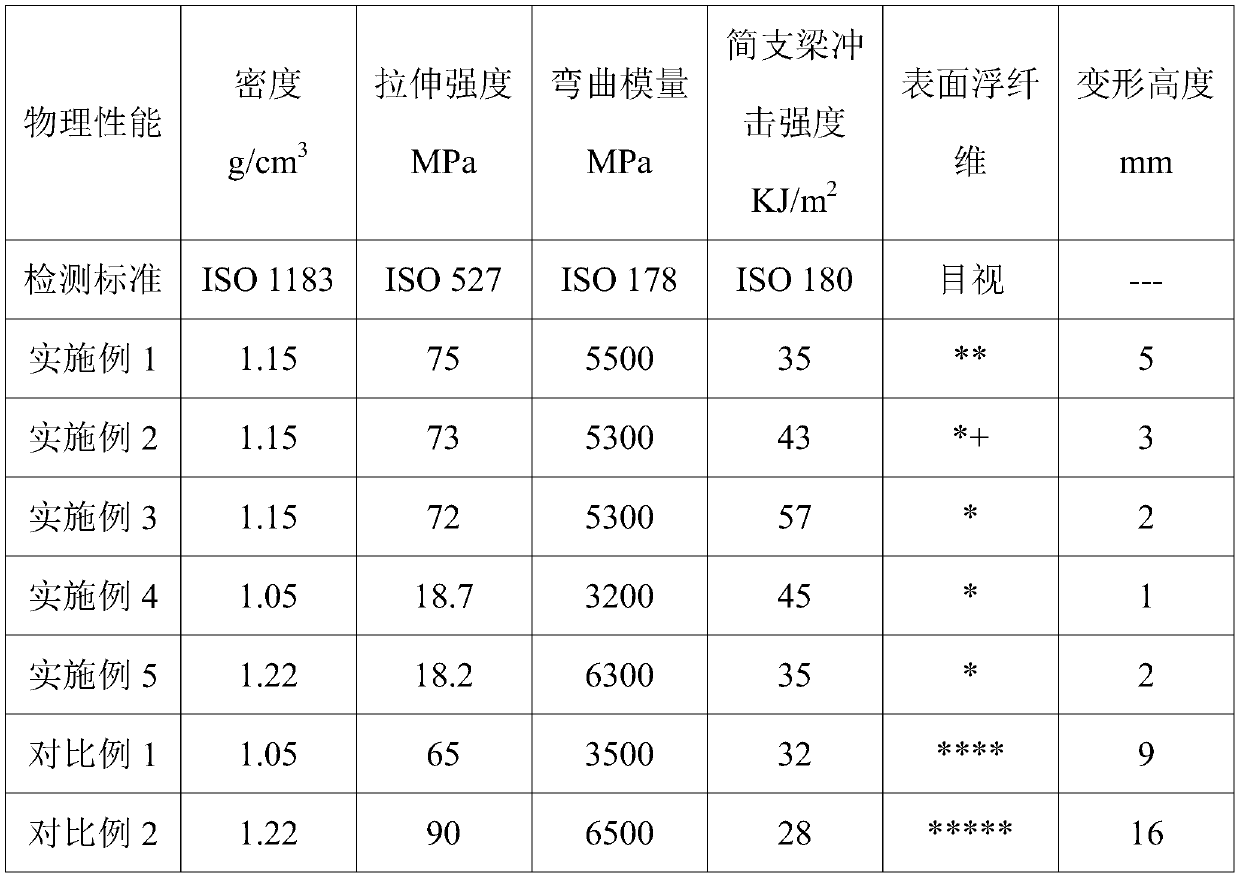

Examples

Embodiment 1

[0032] A kind of good appearance and low warpage polypropylene glass fiber material, its raw materials include by weight: 57 parts of polypropylene, 30 parts of glass fiber, 10 parts of compatibilizer, 3 parts of organopolysiloxane surface modifier, antioxidant 0.1 part of dose;

[0033] Wherein, in the preparation process of the organopolysiloxane surface modifier, the pH=7.5-8 of the polysiloxane emulsion with a solid content of 10% is adjusted with a mass fraction of 5% sodium carbonate aqueous solution, and in a nitrogen atmosphere , stirred and heated up to 85°C, added dropwise styrene, swelled for 30 minutes, then added potassium persulfate aqueous solution, kept the reaction for 4 hours, then added dropwise methyl methacrylate, swelled for 30 minutes, then added potassium persulfate aqueous solution, kept the temperature for 4 hours, cooled to room temperature, break the emulsion, take the solid, wash it, and dry it in vacuum for 24 hours to obtain an organopolysiloxane...

Embodiment 2

[0039] A kind of good appearance and low warpage polypropylene glass fiber material, its raw materials include by weight: 50 parts of polypropylene, 30 parts of glass fiber, 15 parts of compatibilizer, 5 parts of organopolysiloxane surface modifier, antioxidant 1 dose;

[0040] Among them, the preparation methods of organopolysiloxane surface modifier, compatibilizer, polypropylene, glass fiber, and the above-mentioned polypropylene glass fiber material with good appearance and low warpage are the same as in Example 1.

Embodiment 3

[0042] A kind of good appearance and low warpage polypropylene glass fiber material, its raw materials include by weight: 44 parts of polypropylene, 30 parts of glass fiber, 20 parts of compatibilizer, 6 parts of organopolysiloxane surface modifier, antioxidant 1.5 parts of agent;

[0043] Among them, the preparation methods of organopolysiloxane surface modifier, compatibilizer, polypropylene, glass fiber, and the above-mentioned polypropylene glass fiber material with good appearance and low warpage are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com