Polymorphic high-stability resistive random access memory of all-inorganic perovskite thin film and preparation method of polymorphic high-stability resistive random access memory

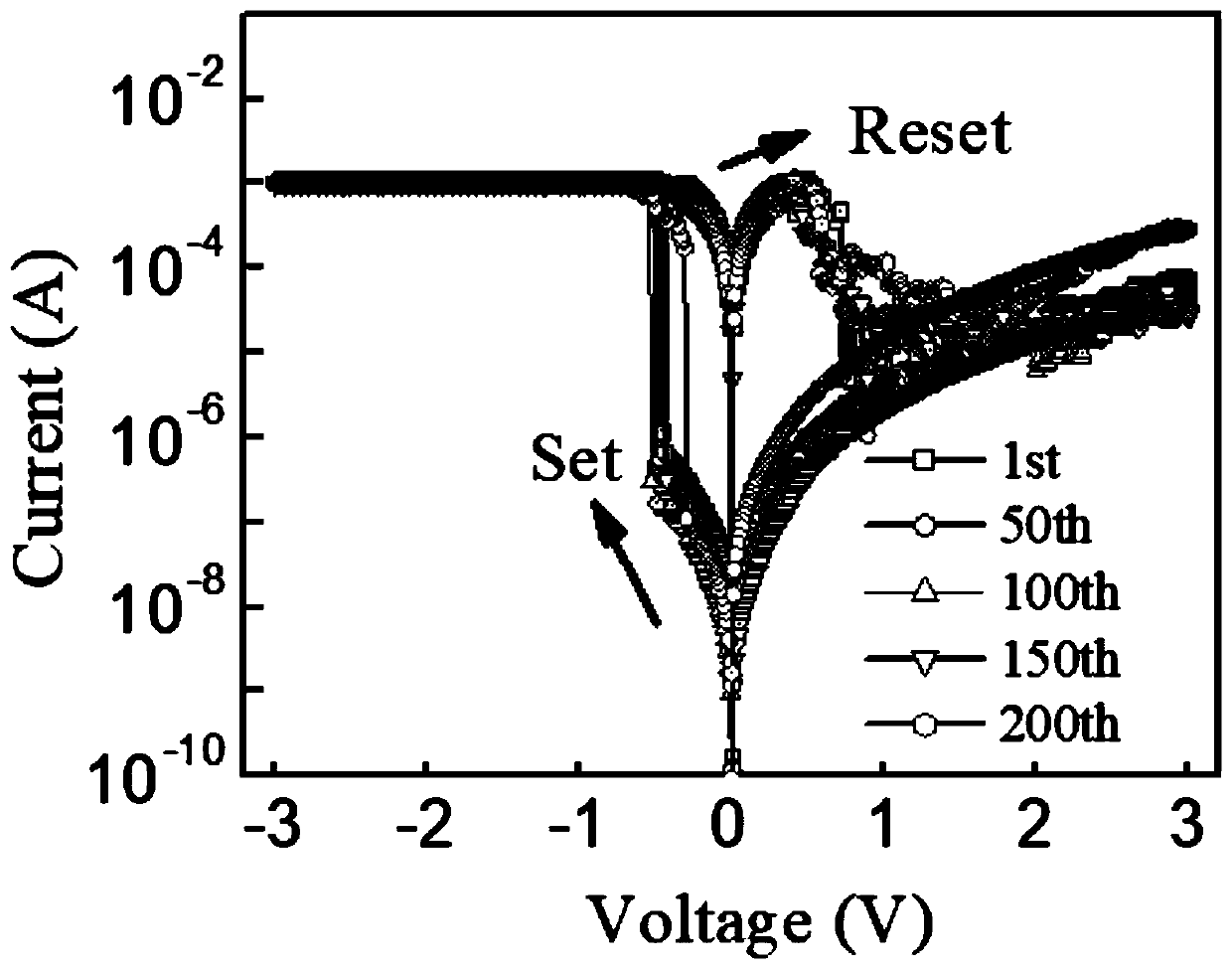

A resistive memory, high-stability technology, applied in electrical components and other directions, can solve problems such as instability of resistive devices, and achieve the effects of good stability, stable performance and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

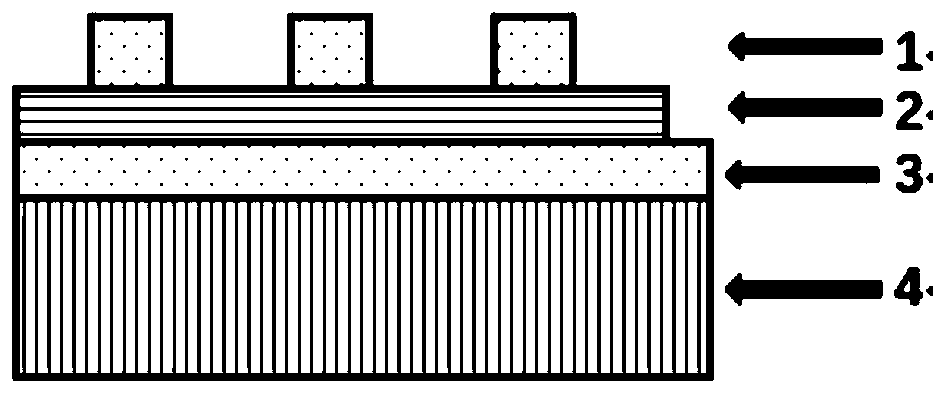

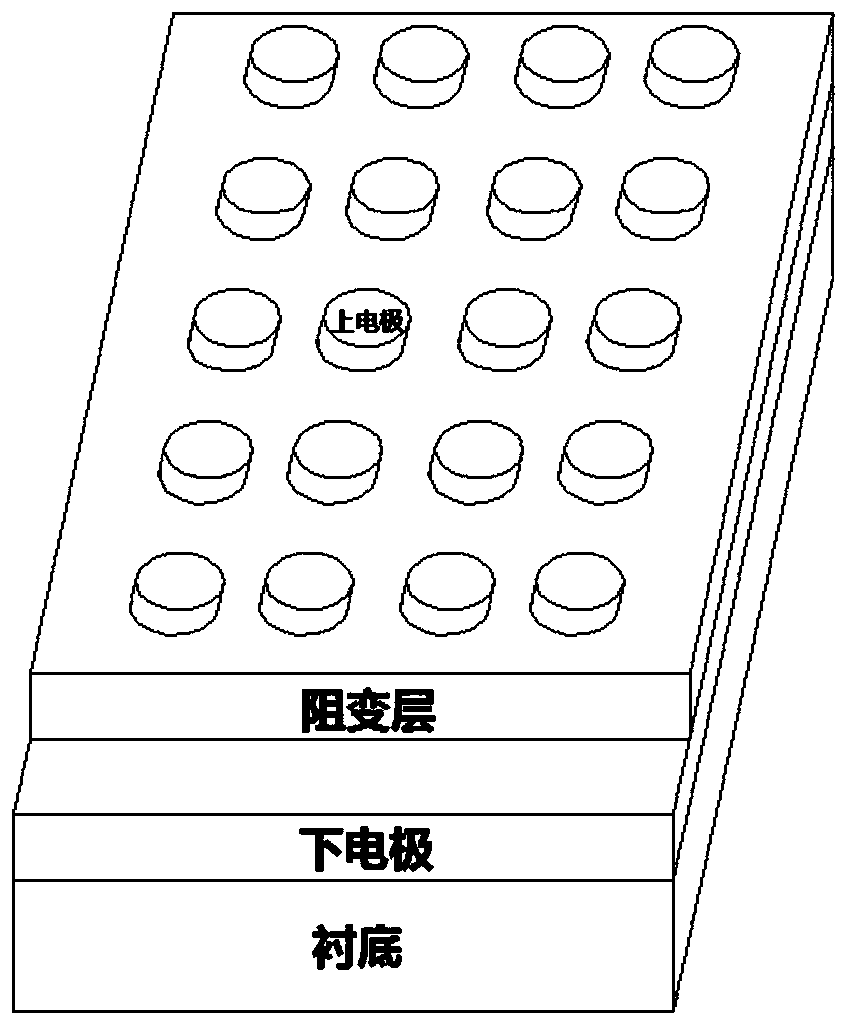

Method used

Image

Examples

Embodiment 1

[0034]1) Mix lead bromide and cesium bromide powders with a mass of 3.6701g and 2.1281g (molar ratio of 1:1), and grind for 1 hour to make the powders fully mixed; put the mixed powder mixture into a nitrogen atmosphere In the environment, the temperature was raised to 600°C at a heating rate of 6°C / min, and then the powder sample was heat-preserved and calcined for 24 hours, and light yellow CsPbBr was obtained after natural cooling. 3 powder;

[0035] 2) Add 0.3ml of dimethyl sulfoxide solution at 65°C to 0.05g of CsPbBr 3 In the powder, and stir slowly and evenly for 15 minutes to dissolve it completely;

[0036] 3) Spin-coat the configured solution at a speed of 3000 rpm on a substrate deposited with a metal platinum film with a thickness of 100 nanometers. The total time of spin coating is 60 seconds. After 10 seconds after the start of high-speed spin coating, add two Chlorobenzene solution was dropped; the prepared film was annealed at 120°C for 40 minutes in a nitrog...

Embodiment 2

[0043] 1) Mix lead bromide and cesium bromide powders with a quality of 3.6701g and 2.1281g, and grind for 1 hour to make the powders fully mixed; Heating rate, the temperature was raised to 600 ° C, and then the powder sample was calcined for 24 hours, and light yellow CsPbBr was obtained after natural cooling 3 powder;

[0044] 2) Add 0.3ml of dimethyl sulfoxide solution at 65°C to 0.05g of CsPbBr 3 In the powder, and stir slowly and evenly for 15 minutes to dissolve it completely;

[0045] 3) The configured solution is spin-coated on a substrate with a metal platinum thin film with a thickness of 100 nanometers at a speed of 4000 rpm. The total time of spin coating is 60 seconds. In the last 20 seconds of spin coating, add two drops of chlorobenzene solution; the prepared film was maintained at a temperature of 120 ° C for 40 minutes in a nitrogen environment, and CsPbBr was obtained after natural cooling 3 thin film, as the resistive layer of the resistive memory;

[0...

Embodiment 3

[0048] 1) Mix lead bromide and cesium bromide powders with a mass of 3.6701g and 2.1281g, and grind for 1 hour to make the powders fully mixed; put the well-mixed powder mixture into a nitrogen environment, and heat at 6°C / min The heating rate was increased to 400 ° C, and then the powder sample was calcined for 24 hours, and light yellow CsPbBr was obtained after natural cooling. 3 powder;

[0049] 2) Add 0.3ml of dimethyl sulfoxide solution at 65°C to 0.05g of CsPbBr 3 In the powder, and stir slowly and evenly for 15 minutes to dissolve it completely;

[0050] 3) The configured solution is spin-coated at a speed of 3000rpm on the substrate deposited with a metal platinum film with a thickness of 100 nm. The total time of spin coating is 60 seconds. In the last 10 seconds of spin coating, add two drops of chlorobenzene solution; the prepared film was maintained at a temperature of 120 ° C for 40 minutes in a nitrogen environment, and CsPbBr was obtained after natural coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com