Biodegradable environment-friendly fabric and preparation method and product thereof

A biodegradable and environmentally friendly technology, applied in the field of textile fabrics, can solve the problems of non-biodegradable, difficult to degrade, and easy to puncture, and achieve the effects of saving manpower and equipment costs, good biodegradability, and optimizing raw material content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

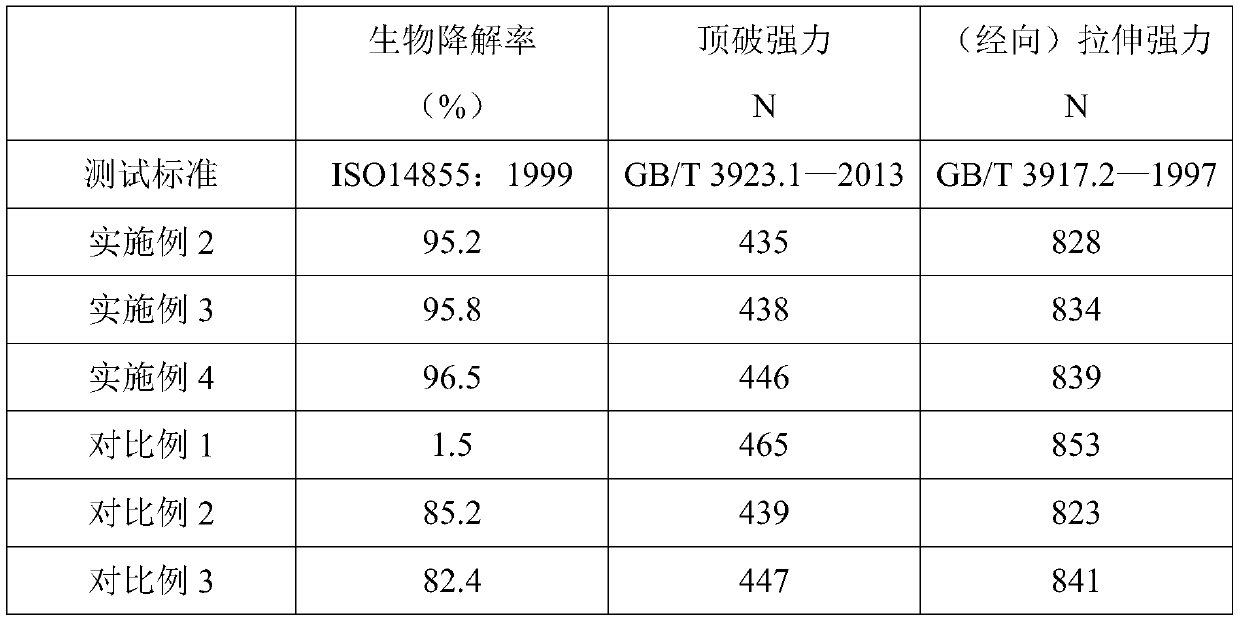

Examples

Embodiment 1

[0042] A biodegradable environmentally friendly fabric, the biodegradable environmentally friendly fabric is made of biodegradable composite fibers through knitting or weaving processes;

[0043] The biodegradable composite fiber is made of raw materials including the following parts by weight:

[0044] 60-70 parts of polyethylene terephthalate,

[0045] 25-32 parts of polybutylene succinate,

[0046] 10-14 parts of polylactic acid,

[0047] 5-7 parts of chitosan,

[0048] 5-7 parts of fumed silica.

[0049] In this embodiment, the biodegradable composite fiber is made of raw materials including the following parts by weight:

[0050] 65 parts of polyethylene terephthalate,

[0051] 27.5 parts of polybutylene succinate,

[0052] 12 parts of polylactic acid,

[0053] Chitosan 6 parts,

[0054] 6 parts of fumed silica.

[0055] In this embodiment, the relative molecular weight of the chitosan is 50,000-80,000, and the degree of deacetylation is 87.5-88.5%.

[0056] In ...

Embodiment 2

[0067] A biodegradable environmentally friendly fabric, the biodegradable environmentally friendly fabric is made of biodegradable composite fibers through knitting or weaving processes;

[0068] The biodegradable composite fiber is made of raw materials including the following parts by weight:

[0069] 60 parts of polyethylene terephthalate,

[0070] 25 parts of polybutylene succinate,

[0071] 10 parts of polylactic acid,

[0072] Chitosan 5 parts,

[0073] 5 parts of fumed silica.

[0074] In this embodiment, the relative molecular weight of the chitosan is 50,000, and the degree of deacetylation is 87.5%.

[0075] In this embodiment, the biodegradable composite fiber further includes the following raw materials in parts by weight: 3 parts of antioxidant.

[0076] In this embodiment, the antioxidant is antioxidant 1010.

[0077] In this embodiment, the biodegradable composite fiber also includes the following raw materials in parts by weight: 3 parts of heat stabilizer....

Embodiment 3

[0086] A biodegradable environmentally friendly fabric, the biodegradable environmentally friendly fabric is made of biodegradable composite fibers through knitting or weaving processes;

[0087] The biodegradable composite fiber is made of raw materials including the following parts by weight:

[0088] 70 parts of polyethylene terephthalate,

[0089] 32 parts of polybutylene succinate,

[0090] 14 parts of polylactic acid,

[0091] Chitosan 7 parts,

[0092] 7 parts of fumed silica.

[0093] In this embodiment, the relative molecular weight of the chitosan is 80,000, and the degree of deacetylation is 88.5%.

[0094] In this embodiment, the biodegradable composite fiber also includes the following raw materials in parts by weight: 4 parts of antioxidant.

[0095] In this embodiment, the antioxidant is antioxidant 1076.

[0096] In this embodiment, the biodegradable composite fiber further includes the following raw materials in parts by weight: 4.5 parts of heat stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com