Ecotype coprocessing technique for country sewage and organic solid castoff

A technology for organic solids and rural sewage, applied in biological water/sewage treatment, biological organic part treatment, biological sludge treatment, etc., can solve problems such as breeding mosquitoes and flies, affecting landscape effects, destroying soil structure and ecological balance, and achieving The effect of increasing ventilation and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

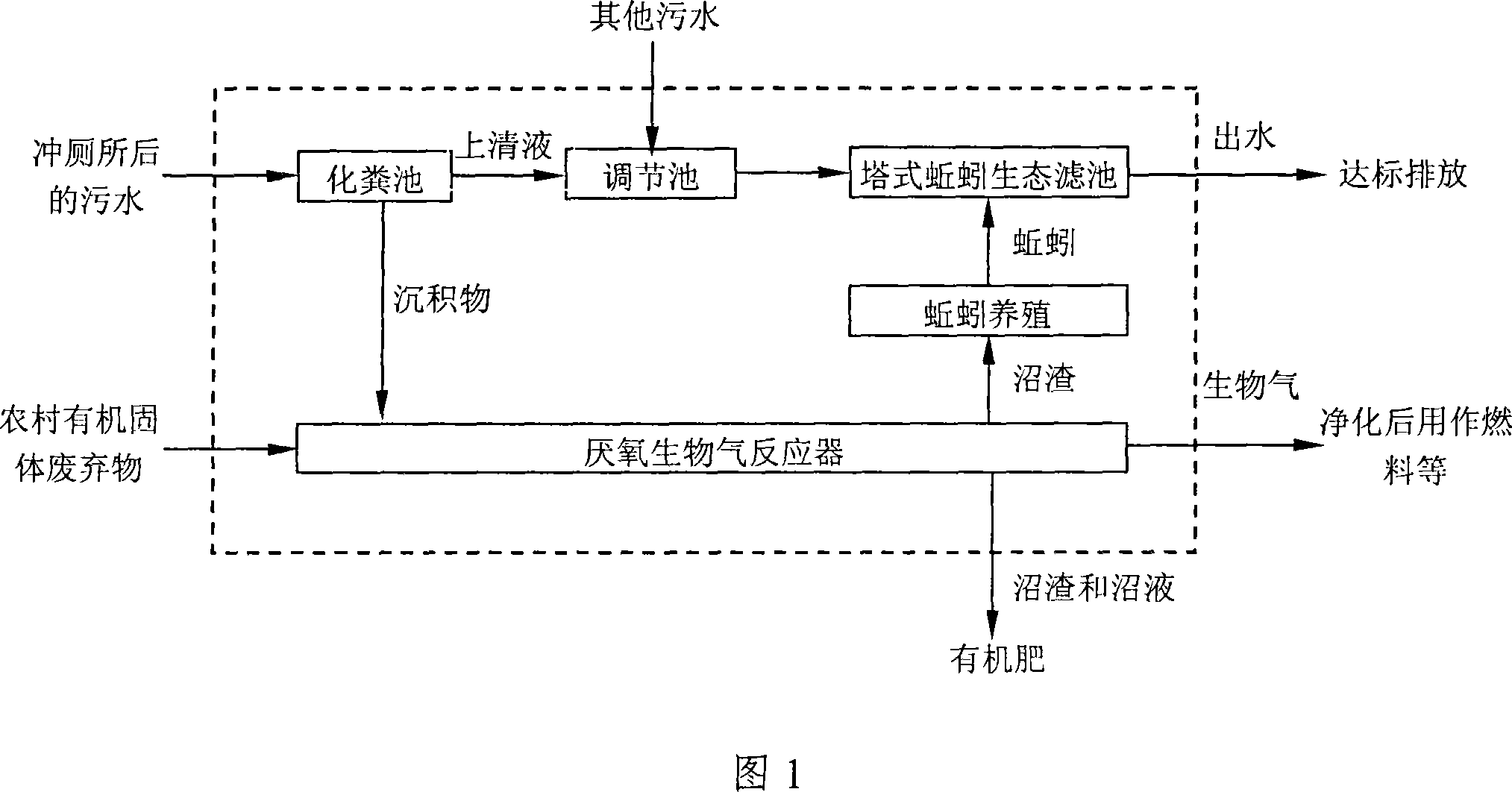

[0020] The supernatant of the septic tank and various sewage discharged from the kitchen and laundry are collected by the pipeline and discharged into the regulating tank for adjustment and mixing. Chemical oxygen demand (COD) in sewage after 4 hours of filter Cr ) and total nitrogen (TN) removal rate of more than 80%, total phosphorus (TP) removal rate of more than 75%. The effluent from the filter can reach the first-level standard of the National Comprehensive Wastewater Discharge Standard (GB8978-1996). The lower sediment collected from the septic tank and the rice straw were mixed evenly at a ratio of 1:6 (mass ratio, the C / N ratio was 26:1), and then put into a fully mixed biogas reactor for anaerobic biological treatment. The fermentation temperature was 55°C, ferment for 40 days with a feeding interval of 15 days, the gas production rate of raw materials can reach up to 380L / kg total solid content (TS), the methane content in biogas is about 55%, and the reactor volum...

Embodiment 2

[0022] The septic tank supernatant and food processing wastewater are collected by the pipeline and discharged into the adjustment tank for adjustment and mixing. The adjusted sewage is pumped into the tower type earthworm ecological filter for treatment, and after 5 hours through the tower type earthworm ecological filter, the sewage in the sewage Chemical Oxygen Demand (COD Cr ) and total nitrogen (TN) removal rate of more than 80%, total phosphorus (TP) removal rate of more than 78%. The effluent of the tower earthworm ecological filter can reach the first-level standard of the national comprehensive sewage discharge standard (GB8978-1996). The lower layer of sediment collected from the septic tank and corn stalks were mixed evenly in a ratio of 3:5 (mass ratio, the C / N ratio was 28:1), and then put into the acid-producing phase of the two-phase biogas reactor. The effluent sewage rich in dissolved organic matter is pumped into the methanogenic phase to complete the methan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com