Austempering multi-purpose furnace production line using oil or oil-atmosphere as quenching medium

A technology of isothermal quenching and using oil, which is applied in the direction of quenching agent, quenching device, furnace, etc., can solve the problems of slow cooling speed, environmental protection, and difficult handling of salt residue, etc., and achieve the effect of stable transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

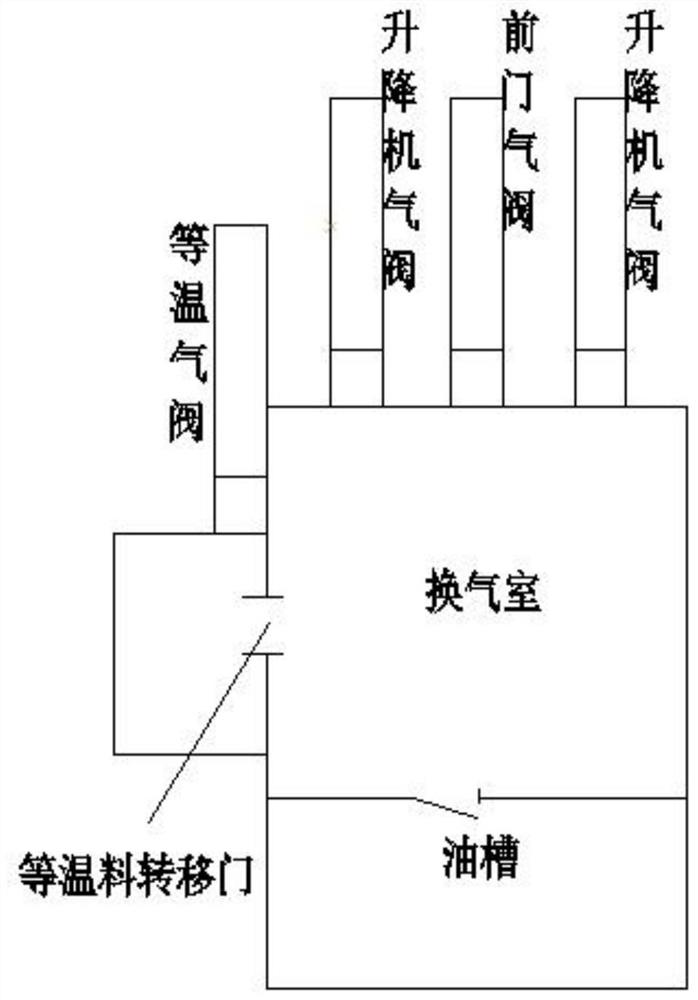

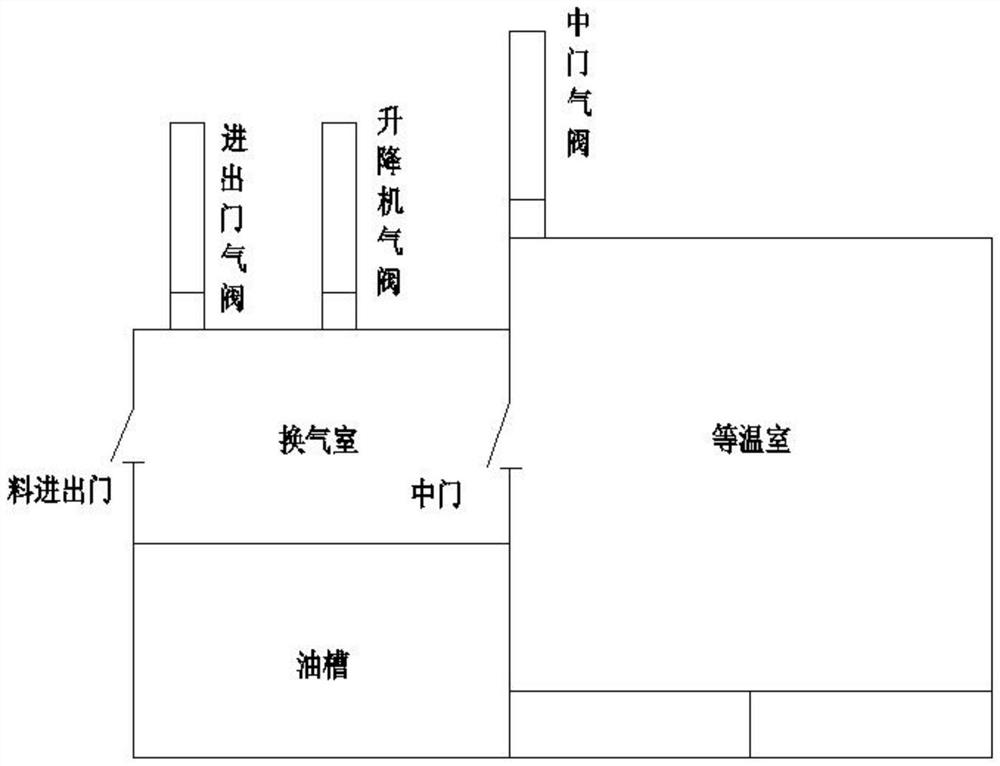

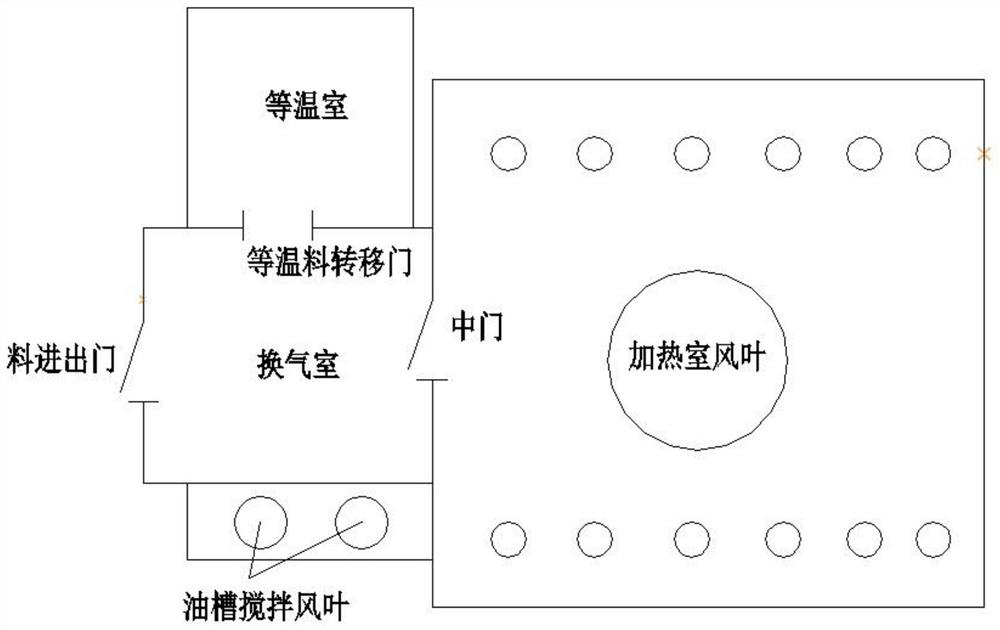

[0040] The SFPID multi-purpose furnace is an internal transfer equipment, equipped with a circulating fan, an alloy radiant tube electric heating system, a closed front room, a quenching oil tank and an isothermal room. The equipment has the function of carbon potential control and is suitable for carburizing, carbonitriding, quenching, annealing, isothermal and other heat treatments that require a controllable atmosphere during heating and quenching. The equipment is equipped with a set of CP controller for controlling the atmosphere in the furnace, and provides a set of PLC and operation man-machine interface.

Embodiment 2

[0042] SFPID multi-purpose furnace is equipped with a set of PLC control program for automatic control. The temperature of the heating furnace is controlled at an appropriate level through the program controller and S.C.R. power regulator. The atmosphere in the equipment is detected by an oxygen probe, and the carbon potential in the furnace is controlled by controlling the propane enrichment system.

[0043]The control program can complete important parameters and component status on the dual-channel controller, and display them on the display, including process time, temperature, CP value, methanol infusion, etc., and record these important parameters on the recorder.

Embodiment 3

[0045] The SFPID multi-purpose furnace is equipped with a transfer robot, which is used to transport workpieces. It consists of a push-pull chain, a push-pull hook, an electric drive mechanism and a manual drive mechanism, and a platform for the operator to stand on. Push zippers have rollers on both sides that run on rails. The push-pull chain only enters the furnace when transporting workpieces, and is hidden under the workbench of the charging cart when it is not working. The drive unit is driven by a motor with a brake. There is a safety pin between the drive unit and the motor as overload protection. The transfer robot is mounted on flanged wheels, driven by a motor reducer with brakes, and runs on a 60-pound track. The robot can move to the attached equipment, namely washing machine, tempering furnace, loading and unloading table.

[0046] The transfer robot can be controlled not only through the touch screen operation control system in the operating room, but also th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com