Polyaniline functionalized graphene conductive ink and preparation method thereof

A kind of conductive ink and polyaniline technology, which is applied in the direction of ink, household appliances, application, etc., can solve the problem of poor ink conductivity, etc., and achieve the effect of improving the conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

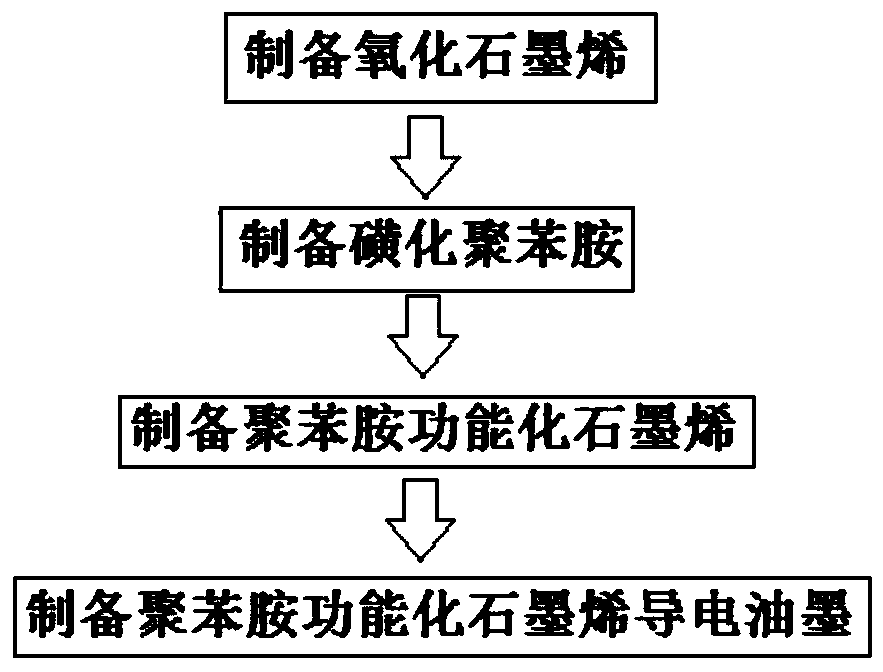

[0030] see figure 1 , which is a flow chart of the polyaniline functionalized graphene conductive ink preparation method of the present invention, the method may further comprise the steps:

[0031] (1) Preparation of graphene oxide

[0032] Methods for preparing graphene include Hummers method, Brodie method, Staudenmaier method and improved Hummers method. Both use graphite or graphene as the raw material for preparation. Although the Brodie method and the Staudenmaier method have a high degree of oxidation, the oxidant potassium chlorate (KClO 3 ), Fuming HNO 3 There are unsafe factors in the reaction process, and ClO will also be produced 2 , NO 2 , N 2 o 4 and other harmful gases. The Hummers method and the improved Hummers method have a short reaction time and high safety, so these two methods are often used to prepare graphene oxide. In this embodiment, the improved Hummers method is preferred to prepare graphene oxide.

[0033] Specifically, the steps for pre...

Embodiment 1

[0052] (1) Preparation of graphene oxide

[0053] First, weigh 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide and add it to 18mL of concentrated sulfuric acid at 80°C, stir evenly, then add 3g of graphite powder, react for 4.5 hours to obtain pre-oxidized graphite, and filter the obtained pre-oxidized graphite Wash and dry overnight. Then, add 1g of sodium nitrate and 1g of pre-oxidized graphite to 60mL of concentrated sulfuric acid in an ice-water bath, stir evenly, slowly add 6g of potassium permanganate, stir for 15 minutes, increase the temperature to 35°C and react for 2 hours. After the reaction was completed, 120 mL of deionized water was slowly added to the reaction liquid, stirred at 80° C. for 30 minutes, and then 365 mL of deionized water and 10 mL of 30% hydrogen peroxide were added in sequence to obtain a khaki mixed liquid. Finally, the mixed solution was washed three times with a 1:10 HCl solution, and then washed with deionized water until neutr...

Embodiment 2

[0066] Step (1), step (2), step (4) and step (5) in this embodiment are completely the same as those in Embodiment 1, and will not be repeated here. The difference between the preparation method of the polyaniline functionalized graphene conductive ink of this embodiment and embodiment 1 is as follows:

[0067] (3) Preparation of polyaniline functionalized graphene

[0068] Step 3-1: Dissolve 100 mg of sulfonated polyaniline prepared in step (2) in 20 mL of 5 mg / mL graphene oxide dispersion prepared in step (1), and react ultrasonically for 1 hour to obtain polyaniline oxide Graphene dispersion;

[0069] Step 3-2: Add 1 g of ascorbic acid to the polyaniline graphene oxide dispersion prepared in step 3-1, reflux at 60° C. for 8 hours, obtain a polyaniline-functionalized graphene dispersion after the reflux reaction, and functionalize the polyaniline After the graphene dispersion is washed and freeze-dried, the polyaniline functionalized graphene solid is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com