Graphene waterborne super-wear-resisting floor paint and preparation method thereof

A water-based, ultra-wear-resistant technology, applied in the field of floor paint, can solve the problems of easy agglomeration of graphene, achieve the effects of inhibiting penetration, enhancing mechanical properties, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

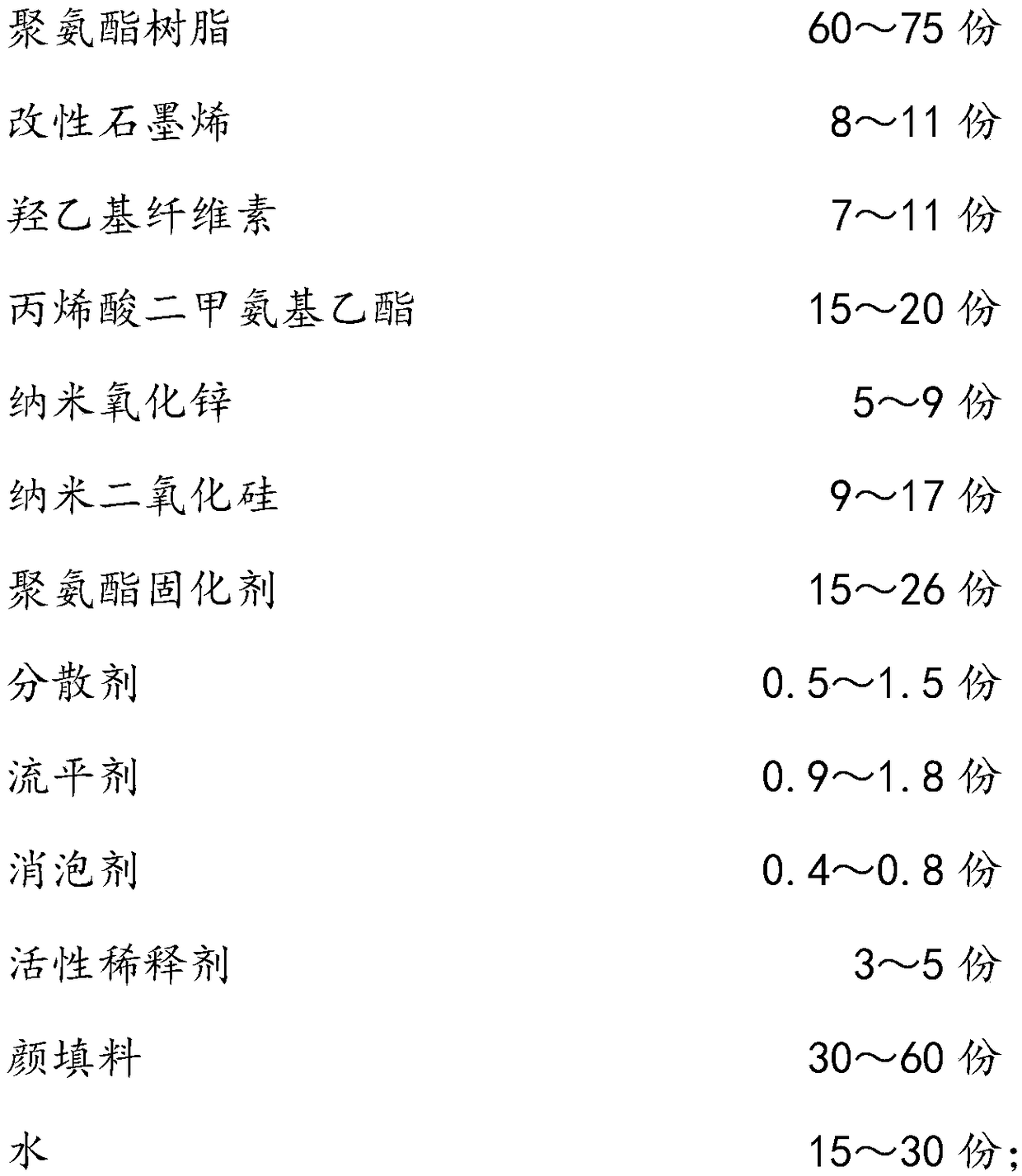

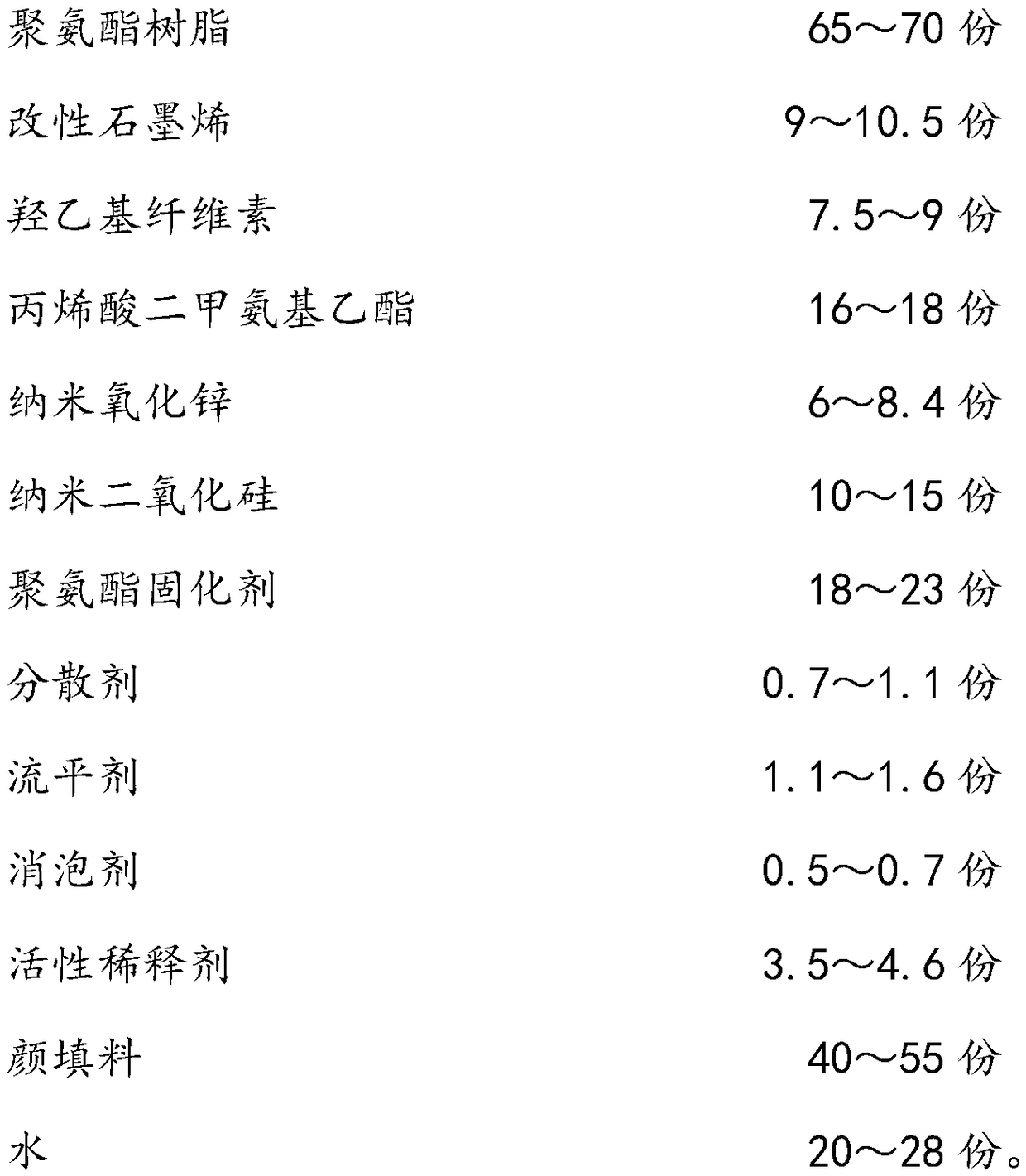

Method used

Image

Examples

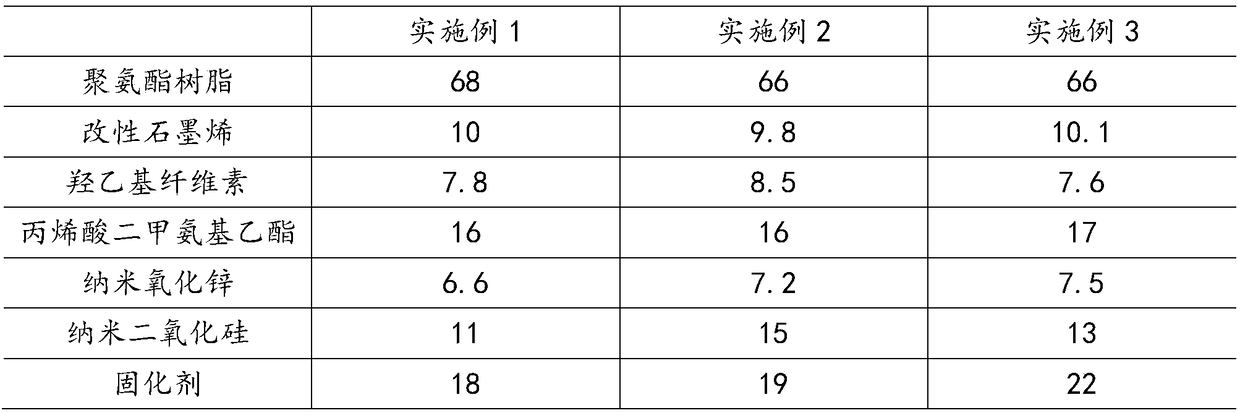

Embodiment 1

[0036] Step 1. Mix 68 parts of polyurethane resin, 7.8 parts of hydroxyethyl cellulose and 23 parts of water, stir at a speed of 900 rpm, and simultaneously add 16 parts of dimethylaminoethyl acrylate, 0.8 parts of dispersant, and 3.6 parts of active Thinner, stirring time is 80min;

[0037] Step 2, put the product of step 1 into a grinder, add 6.6 parts of nano-zinc oxide, 11 parts of nano-silicon dioxide and 10 parts of modified graphene, and stir at a speed of 2000 rpm for 100 min;

[0038] Step 3. Put the product of step 2 into the mixer, add 1.1 parts of leveling agent, 43 parts of pigments and fillers, 0.5 parts of defoamer, 18 parts of curing agent, stir at 1050 rpm for 50 minutes, and filter to get The graphene water-based super wear-resistant floor paint.

Embodiment 2

[0040] Step 1. Mix 68 parts of polyurethane resin, 8.5 parts of hydroxyethyl cellulose and 27 parts of water, stir at a speed of 900 rpm, and simultaneously add 16 parts of dimethylaminoethyl acrylate, 0.8 parts of dispersant, 4.1 parts of active Thinner, stirring time is 80min;

[0041] Step 2, put the product of step 1 into a grinder, add 7.2 parts of nano-zinc oxide, 15 parts of nano-silicon dioxide and 9.8 parts of modified graphene, and stir at a speed of 2000 rpm for 100 min;

[0042] Step 3. Put the product of step 2 into the mixer, add 1.4 parts of leveling agent, 0.6 parts of defoamer, 51 parts of pigment and filler, 19 parts of curing agent, stir at 1050 rpm for 50 minutes, and filter to get The graphene water-based super wear-resistant floor paint.

Embodiment 3

[0044] Step 1. Mix 66 parts of polyurethane resin, 7.6 parts of hydroxyethyl cellulose and 22 parts of water, stir at a speed of 900 rpm, and simultaneously add 17 parts of dimethylaminoethyl acrylate, 1 part of dispersant, 4.5 parts of active Thinner, stirring time is 80min;

[0045] Step 2, put the product of step 1 into a grinder, add 7.5 parts of nano-zinc oxide, 13 parts of nano-silicon dioxide and 10.1 parts of modified graphene, and stir at a speed of 2000 rpm for 100 min;

[0046] Step 3. Put the product of step 2 into the mixer, add 1.5 parts of leveling agent, 0.7 parts of defoamer, 48 parts of pigment and filler, 22 parts of curing agent, stir at 1050 rpm for 50 minutes, and filter to get The graphene water-based super wear-resistant floor paint.

[0047] Wherein, the embodiment of the specific preparation method of modified graphene is as follows, and wherein parts are parts by weight:

[0048] Step 1. Oxidize graphene by the Hummers method to obtain 1 part of gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com