Hydrogenated nitrile rubber reinforcing agent as well as preparation method and application thereof

A hydrogenated nitrile rubber and reinforcing agent technology, which is applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of poor reinforcement effect and poor dispersion, and achieve good reinforcement, easy control, and excellent dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

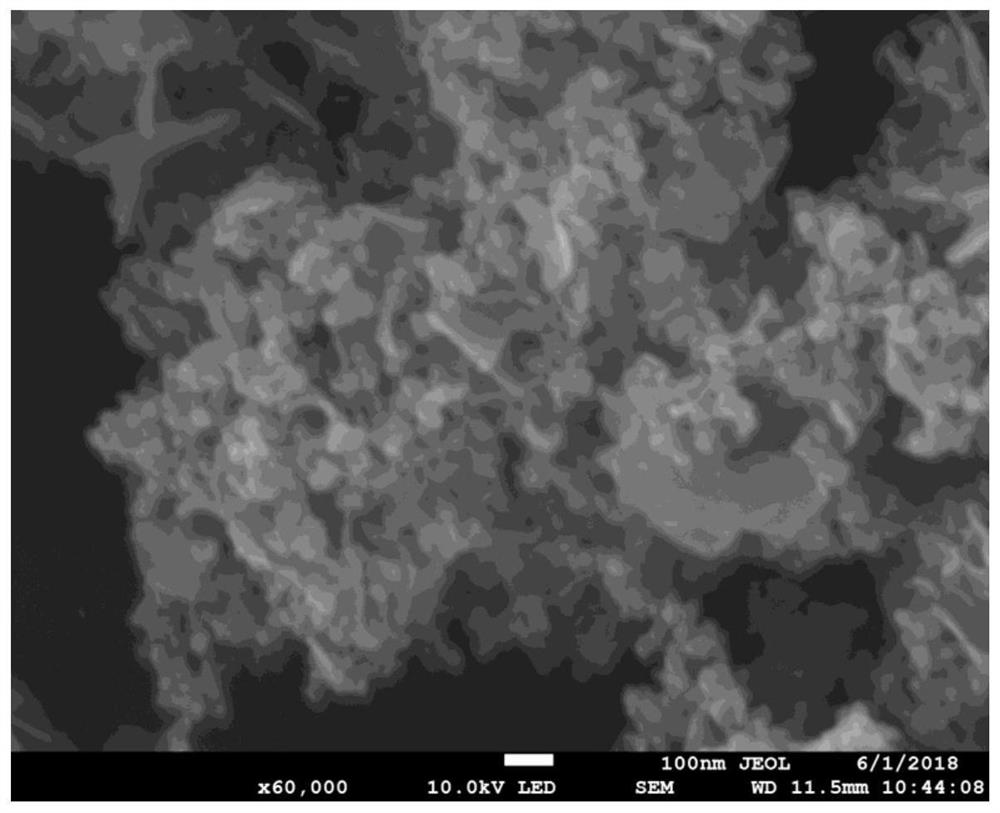

[0041] Preparation of hydrogenated nitrile rubber reinforcing agent

[0042] (1) Weigh 25g of liquid-phase nano-silicon dioxide particle powder in a three-necked bottle, add 82.48ml of commercially available 0.5mol / L sodium carbonate aqueous solution, and sonicate at room temperature for 2.5 hours to fully disperse nano-silica particles in sodium carbonate aqueous solution;

[0043](2) under the action of mechanical stirring, in the there-necked flask in the step (1), dropwise add the 0.5mol / L hexahydrate zinc nitrate solution of 82.48ml and the 0.25mol / L nonahydrate aluminum nitrate solution of 82.48ml, the solution drips The acceleration is 1 to 3 drops / second, and the mixture is fully stirred to obtain a mixed solution;

[0044] (3) under mechanical stirring, use commercially available 2mol / L aqueous sodium hydroxide solution to adjust the pH=9.0 of the mixed solution in step (2) dropwise, and maintain for 2 hours to obtain hydrotalcite-silica slurry;

[0045] (4) after...

Embodiment 2

[0052] Preparation of hydrogenated nitrile rubber reinforcing agent

[0053] (1) Weigh 25g of liquid-phase nano-silicon dioxide particle powder in a three-necked bottle, add 61.86ml of commercially available 0.5mol / L sodium carbonate aqueous solution, and ultrasonicate at room temperature for 2 hours to fully disperse nano-silica particles in sodium carbonate aqueous solution;

[0054] (2) under the action of mechanical stirring, in the there-necked flask in the step (1), drip the 0.3mol / L hexahydrate zinc nitrate solution of 103.1ml and the 0.5mol / L nonahydrate aluminum nitrate solution of 30.93ml, the solution drips The acceleration is 1 to 3 drops / second, and the mixture is fully stirred to obtain a mixed solution;

[0055] (3) under mechanical stirring, use commercially available 2mol / L aqueous sodium hydroxide solution to adjust the pH=9.5 of the mixed solution in step (2) dropwise, and maintain for 2.5 hours to obtain hydrotalcite-silica slurry;

[0056] (4) after th...

Embodiment 3

[0061] Preparation of hydrogenated nitrile rubber reinforcing agent

[0062] (1) Weigh 25g of liquid-phase nano-silicon dioxide particle powder in a three-necked bottle, add 41.24ml of commercially available 0.5mol / L sodium carbonate aqueous solution, and ultrasonicate at room temperature for 3 hours to make the nano-silica particles fully Disperse in sodium carbonate aqueous solution;

[0063] (2) under the action of mechanical stirring, in the there-necked flask in the step (1), drip the hexahydrate zinc nitrate solution of 0.5mol / L of 41.24ml and the nonahydrate aluminum nitrate solution of 0.6mol / L of 17.18ml, the solution drips The acceleration is 1 to 3 drops / second, and the mixture is fully stirred to obtain a mixed solution;

[0064] (3) under the action of mechanical stirring, use commercially available 2mol / L sodium hydroxide solution dropwise to adjust the pH=8.5 of the mixed solution in step (2), and maintain for 2 hours to obtain hydrotalcite-silica slurry;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com