Method for purifying gram-grade mechanical functional proteins on large scale

A large-scale, mechanical technology, applied in the field of bioengineering, can solve problems such as difficult control of reversible phase transition conditions, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

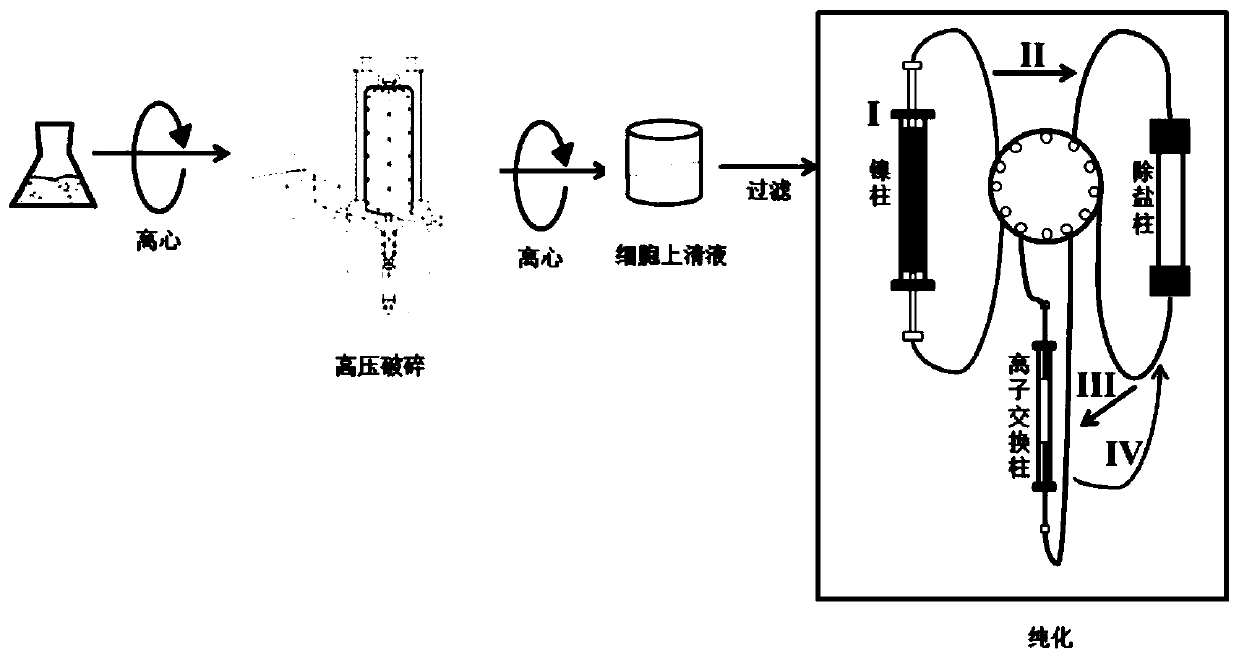

[0054] 1. Sample pretreatment

[0055] Put 2L of Escherichia coli fermentation broth containing SRT protein into a centrifuge, centrifuge in batches, 8000rpm for 20min, collect the precipitate, wash with equilibration buffer A and centrifuge in the same way, repeat three times. A total of 100g of bacterial cells were collected, and then 400ml of equilibrium buffer A was added. After crushing by a high-pressure crusher, centrifuge at 8000rpm for 20min. Dilute to 200mL to finally obtain 200mL of pretreated protein samples.

[0056] 2. Nickel column purification of SRT protein

[0057] Purify the pretreated protein obtained in step 1 through a nickel affinity chromatography column, the column used is HisTrap6XFF 5ml, and the specific purification steps are:

[0058] 2.1 Buffer preparation

[0059] (1) Equilibration buffer A:

[0060]

[0061] Add HCl to adjust pH=8.0

[0062] (2) Elution buffer A:

[0063] Equilibrium buffer A was used to prepare a buffer with a final co...

Embodiment 2

[0119] 1. Sample pretreatment

[0120] Put 20L E. coli fermentation broth containing recombinant Resilin protein into a continuous flow centrifuge, collect the precipitate continuously, wash with equilibration buffer A and centrifuge in the same way, repeat three times. A total of 1 kg of bacteria was collected, and then 5L of equilibrium buffer A was added, crushed by a high-pressure crusher, centrifuged at 8000rpm for 20min, and the obtained supernatant was filtered with a 0.45μm filter membrane to remove bacteria while removing macromolecules, and finally obtained 5L of pre- Process protein samples.

[0121] 2. Purification of Resilin protein by large-volume nickel column

[0122] Purify the pretreated protein obtained in step 1 through a large-volume nickel affinity chromatography column, and the filler used is NiSepharose TM 6Fast Flow high-flow nickel affinity chromatography packing material, the total nickel ion binding capacity of the packing material is not less tha...

Embodiment 3、4

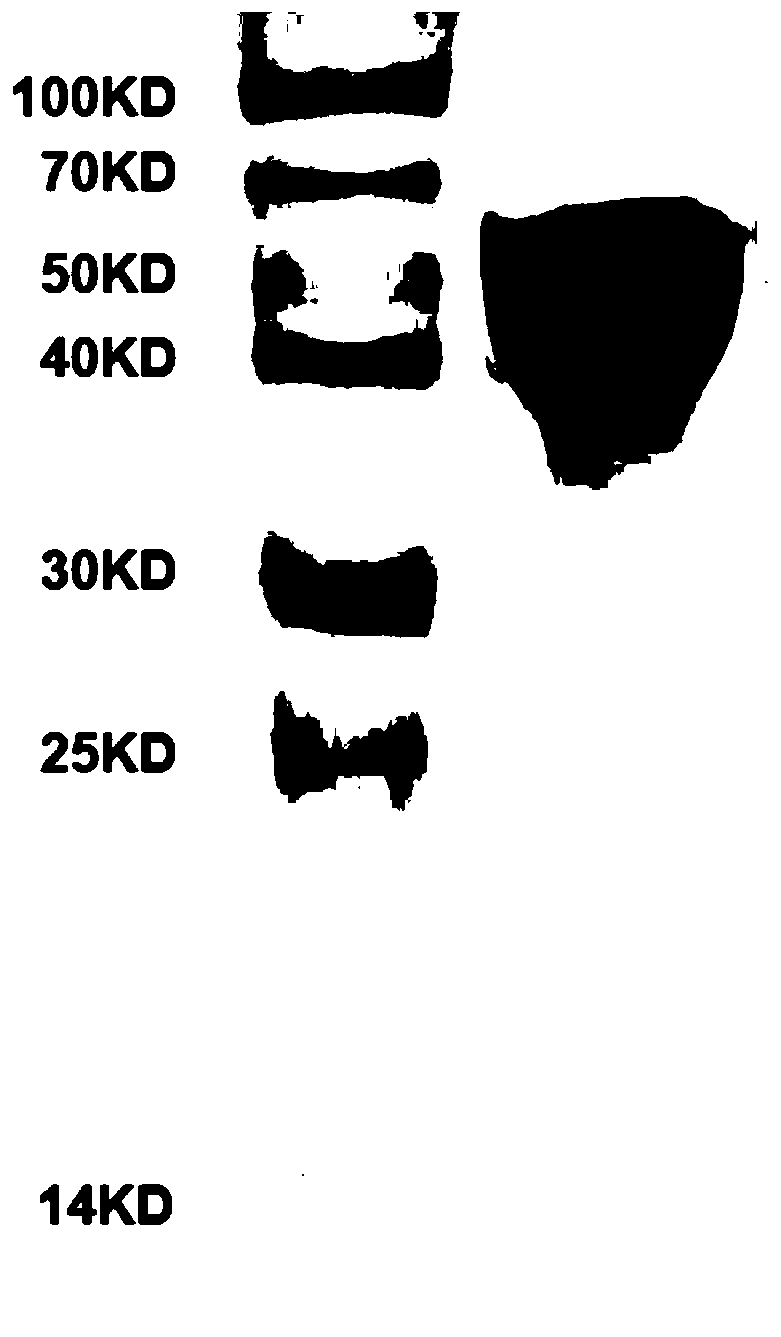

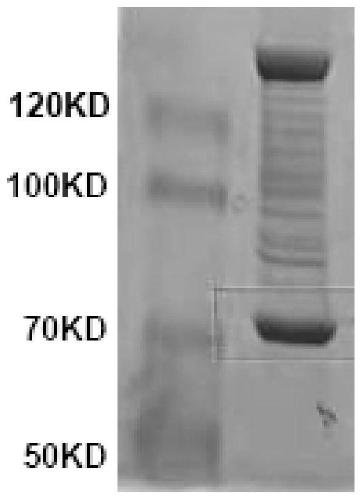

[0182] Similar to the operation method in Example 2, the difference is that the protein is replaced by spidroin and elastin. see results Figure 4-5 .

[0183] The results show, Figure 4 The spidroin protein purity in it reaches 90%, which meets the requirements. Figure 5 The purity of the individual ELPs in is very high, and its purity reaches 99% after analysis, which shows that the expression effect and purification effect of this tag are excellent, and it is extremely effective as a fusion expression tag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com