Stainless steel welding rod capable of resisting redness and cracking of coating

A technology of stainless steel and coating, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of reduced adhesion of coating, insufficient metallurgical reaction, poor conductivity, etc., to improve anti-redness and Cracking ability, improvement of anti-redness and cracking performance, effect of enhancing anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

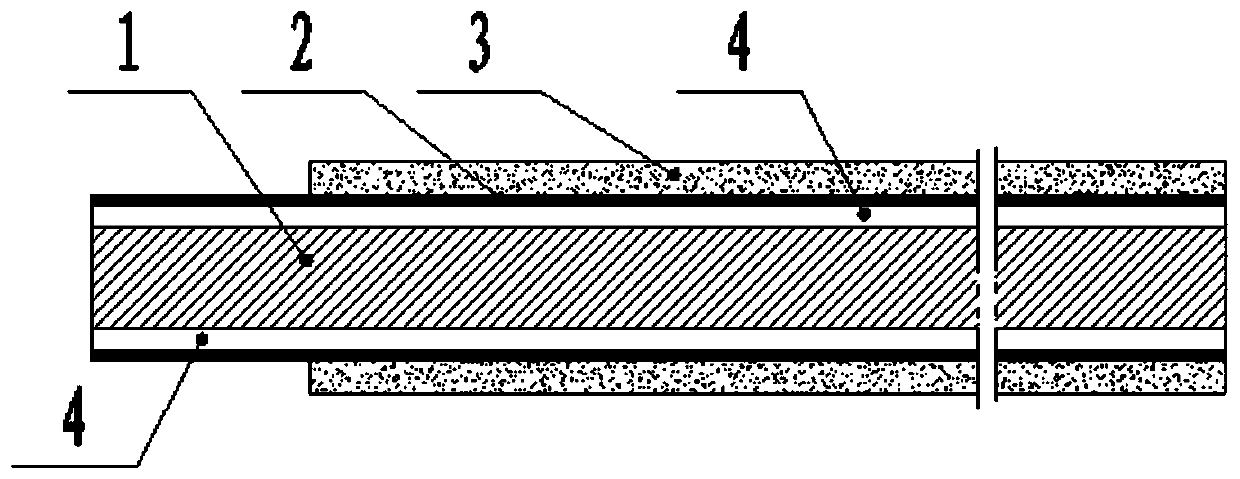

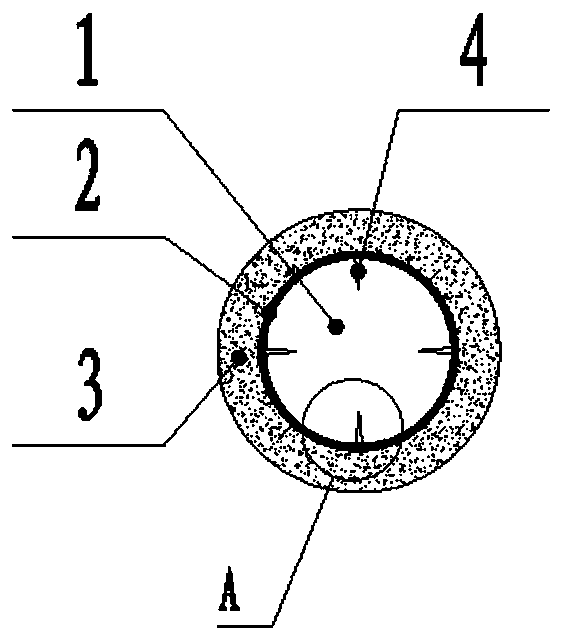

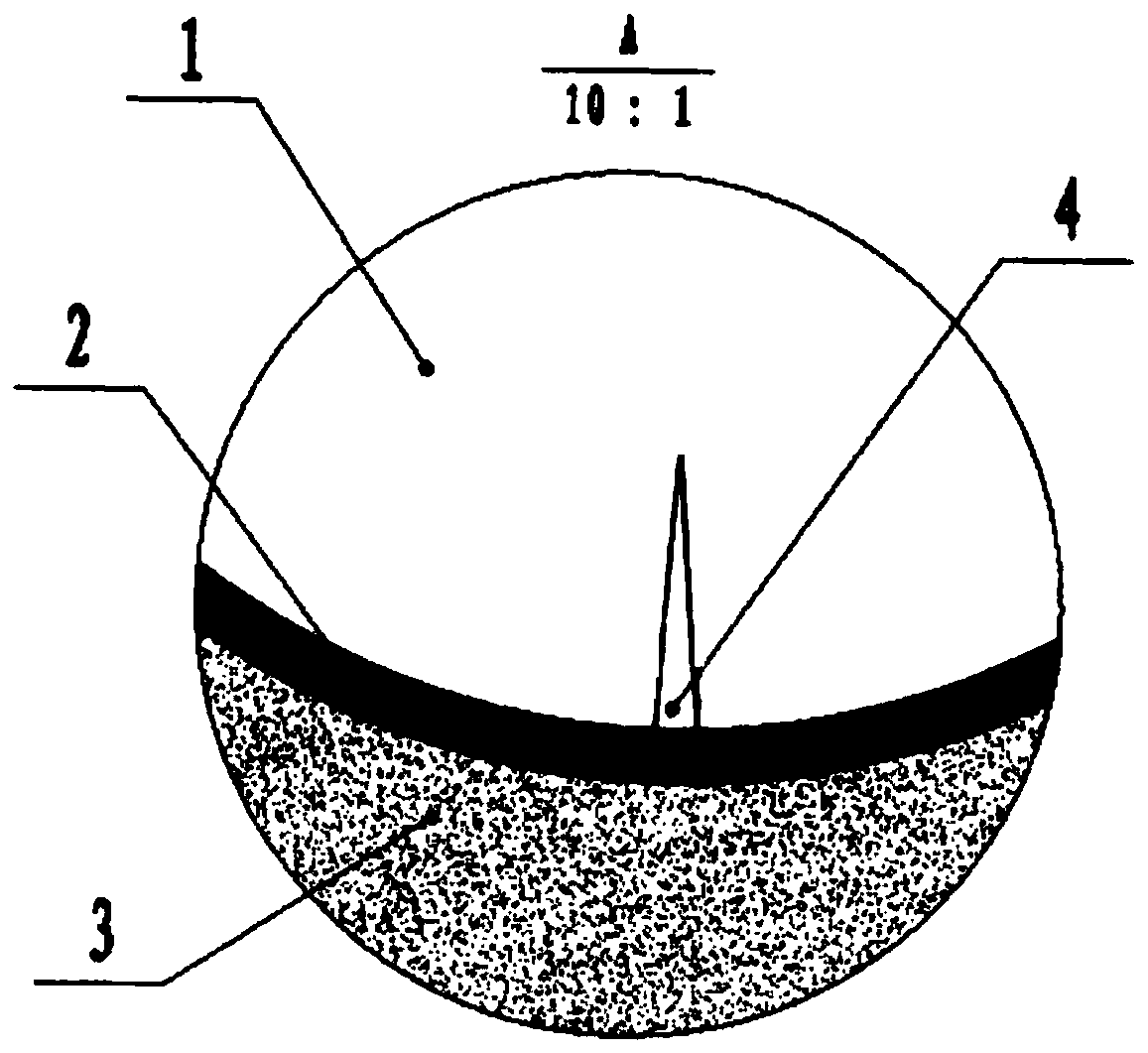

[0058] Prepare the anti-drug skin redness and cracking stainless steel welding rod of the present invention, the composition of dry powder is calculated by mass percent: rutile 10%, mica 8%, calcium carbonate 8%, magnesium carbonate 10%, nickel carbonate 5%, white 3% mud, 2% zirconia, 8% fluorite, 1% spodumene, 5% ferromanganese, 3% ferrotitanium, 6% ferrosilicon, 0.2% sodium alginate, 0.15% carboxymethyl cellulose, nano Cerium oxide and / or nanometer yttrium oxide and / or nanometer lanthanum oxide 1.5%, the rest is potassium feldspar; binder is potassium sodium water glass, wherein the molar ratio of potassium ion and sodium ion is 1:2, potassium sodium water glass The modulus is 2.95, and the Baume concentration of sodium potassium water glass is 48.5 ° B é; The quality of binder is 29% of dry powder total mass in the coating, and the width of V-shaped groove is 0.2mm, and the depth of groove is 0.8mm; the number of V-shaped grooves is 3, and the thickness of the copper platin...

Embodiment 2

[0060] Prepare the anti-drug skin redness and cracking stainless steel welding rod of the present invention, the composition of dry powder is calculated by mass percent: rutile 12%, mica 10%, calcium carbonate 10%, magnesium carbonate 12%, nickel carbonate 8%, white 5% clay, 4% zirconia, 10% fluorite, 3% spodumene, 7% ferromanganese, 6% ferrotitanium, 8% ferrosilicon, 0.3% sodium alginate, 0.25% carboxymethyl cellulose, nano Cerium oxide and / or nanometer yttrium oxide and / or nanometer lanthanum oxide 2%, the rest is potassium feldspar; binder is potassium sodium water glass, wherein the molar ratio of potassium ion and sodium ion is 1: 2, potassium sodium water glass The modulus is 3.05, and the Baume concentration of potassium sodium water glass is 50.5 ° Bé; The quality of binding agent is 32% of dry powder total mass in the drug skin, and the width of V-shaped groove is 0.4mm, and the width of described groove The depth is 1.2 mm; the number of V-shaped grooves is 8, and th...

Embodiment 3

[0062] Prepare the anti-drug skin rubescent and cracking stainless steel welding rod of the present invention, the composition of dry powder is calculated by mass percent: 11% of rutile, 9% of mica, 9% of calcium carbonate, 11% of magnesium carbonate, 6.5% of nickel carbonate, white Clay 4%, Zirconia 3%, Fluorite 9%, Spodumene 2%, Ferromanganese 6%, FerroTitanium 4.5%, Ferrosilicon 7%, Sodium Alginate 0.25%, Carboxymethyl Cellulose 0.2%, Nano Cerium oxide and / or nanometer yttrium oxide and / or nanometer lanthanum oxide 1.75%, the rest is potassium feldspar; Binder is potassium sodium water glass, wherein the molar ratio of potassium ion and sodium ion is 1:2, potassium sodium water glass The modulus is 3, and the Baumé concentration of sodium potassium water glass is 49.5°Bé; the quality of the binder is 30.5% of the total mass of the dry powder in the drug skin. The width of the V-shaped groove is 0.3 mm, and the depth of the groove is 1.0 mm; the number of V-shaped grooves is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com