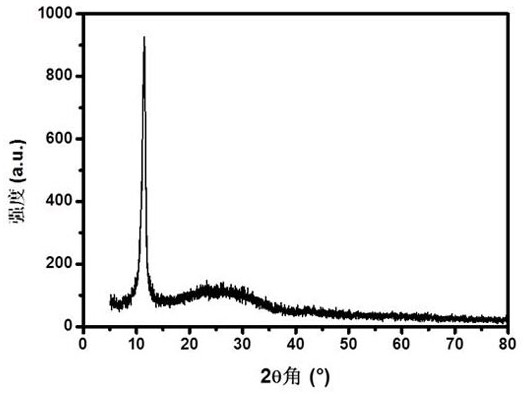

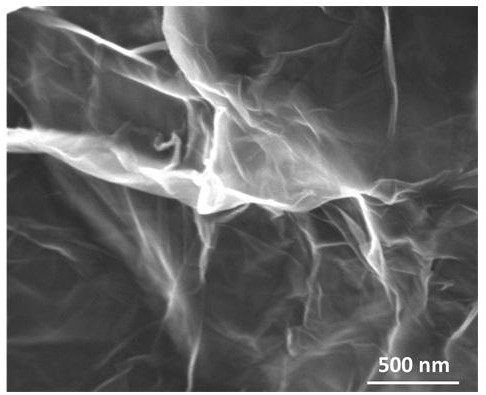

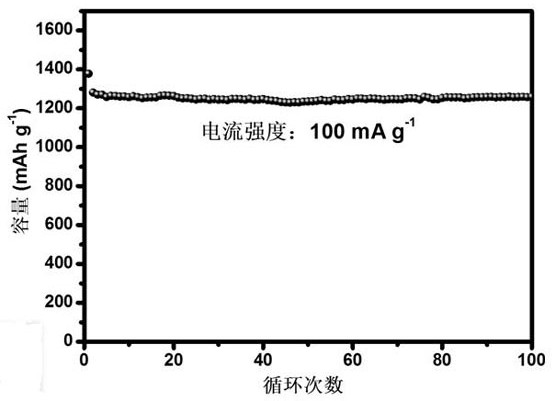

A nitrogen-doped molybdenum disulfide/c/graphene composite material

A technology of molybdenum disulfide and composite materials, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of low nitrogen doping content, difficulty in obtaining raw materials, low product utilization rate, etc., and achieve large specific surface area and stability Good, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh 1.0g of graphene oxide and disperse it in 20mL of 37% formaldehyde aqueous solution, place it in an ultrasonic instrument and disperse evenly, record it as dispersion A.

[0042] (2) Take 0.5g ammonium paramolybdate and 20mL concentrated ammonia water (NH 3 ·H 2 O) Mix, heat up, add 3.0g ammonium sulfide ((NH 4 ) 2 S), reacted for 0.5 h under the state of magnetic stirring, and then respectively added 0.1 g of tetramethylammonium bromide and 0.6 g of melamine to the solution, and ultrasonically mixed them uniformly to obtain dispersion B.

[0043] (3) Mix Dispersion A and Dispersion B, raise the temperature of the water bath to 60°C and stir for 10 minutes. Then triethanolamine was added to the reaction solution to adjust the pH value of the reaction solution system to 8.0, and the mixture was uniformly mixed by ultrasonic, then the reaction solution was poured into a high-pressure reactor, and the temperature was raised to 120° C. for 12 hours to react. S...

Embodiment 2

[0046] (1) Weigh 1.0g of graphene oxide and disperse it in 20mL of 37% formaldehyde aqueous solution, place it in an ultrasonic instrument and disperse evenly, record it as dispersion A.

[0047] (2) Take 0.5g ammonium paramolybdate and 20mL concentrated ammonia water (NH 3 ·H 2 O) Mix, heat up, add 9.0g ammonium sulfide ((NH 4 ) 2 S), reacting for 1 h under magnetic stirring, then adding 2.0 g of tetramethylammonium bromide and 2.0 g of melamine to the solution, and ultrasonically mixing to obtain a dispersion B.

[0048] (3) Mix Dispersion A and Dispersion B, raise the temperature of the water bath to 60°C and stir for 10 minutes. Then triethanolamine was added to the reaction solution to adjust the pH value of the reaction solution system to 8.0, and the mixture was uniformly mixed by ultrasonic, then the reaction solution was poured into a high-pressure reactor, and the temperature was raised to 120° C. for 12 hours to react. Suction filtration, vacuum drying to obtain...

Embodiment 3

[0051] (1) Weigh 1.0g graphene oxide and disperse it in 30mL 37% formaldehyde aqueous solution, place it in an ultrasonic instrument and disperse evenly, record it as dispersion liquid A.

[0052] (2) Take 0.9g ammonium paramolybdate and 20mL concentrated ammonia water (NH 3 ·H 2 O) Mix, heat up, add 10.0g ammonium sulfide ((NH 4 ) 2 S), reacted for 1 h under the state of magnetic stirring, and then respectively added 2.5 g of tetraethylammonium bromide and 2.0 g of melamine to the solution, and ultrasonically mixed them uniformly to obtain dispersion B.

[0053] (3) Mix Dispersion A and Dispersion B, raise the temperature of the water bath to 70°C and stir for 10 minutes. Then triethanolamine was added to the reaction solution to adjust the pH value of the reaction solution system to 8.0, and the mixture was uniformly mixed by ultrasonic, then the reaction solution was poured into a high-pressure reactor, and the temperature was raised to 120° C. for 12 hours to react. Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com