A nitrogen-doped molybdenum disulfide/three-dimensional graphene composite material

A technology of molybdenum disulfide and composite materials, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of low product utilization, complicated and time-consuming operations, and difficulties in obtaining raw materials, achieving fast heating speed, firm combination, The effect of not easy to accumulate particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh 1.0 g of graphene oxide and 3.0 g of L-cysteine and disperse them in 20 mL of 37% formaldehyde aqueous solution, and place them in an ultrasonic machine to disperse evenly and record as dispersion liquid A.

[0042] (2) Weigh 3.0 g of melamine, 1.2 g of sulfur powder and 5.2 g of ammonium paramolybdate into 40 mL of deionized water, and place them in an ultrasonic machine to disperse them uniformly and record as dispersion B.

[0043] (3) Mix Dispersion A and Dispersion B, heat the water bath to 60°C and stir for 10min. Subsequently, triethanolamine was added to the reaction solution, the pH value of the reaction solution system was adjusted to 8.0, and the mixture was ultrasonically mixed evenly. The resulting solid was freeze-dried.

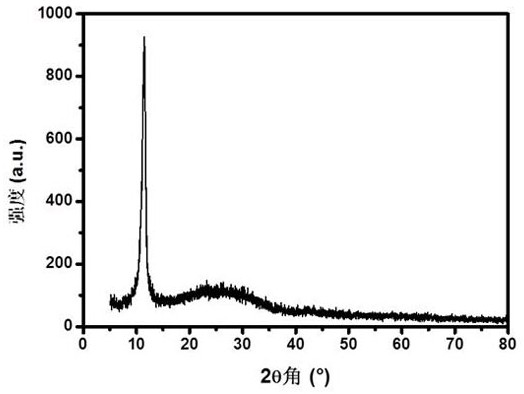

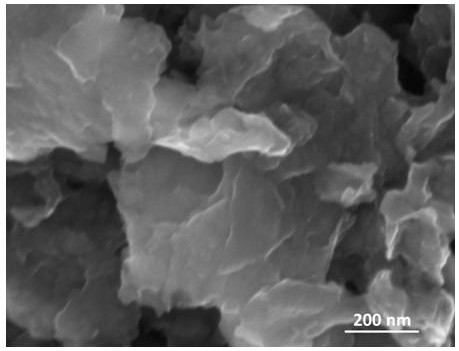

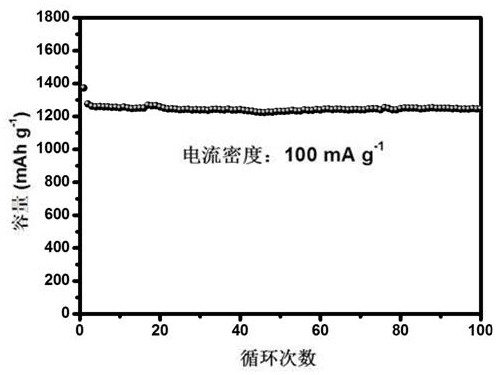

[0044] (4) The product obtained in step (3) was placed in a microwave reaction chamber, and 100 mL / min of argon was purged for 1 h. The nitrogen-doped molybdenum disulfide / three-dimensional graphene composite material was o...

Embodiment 2

[0046] (1) Weigh 1.0 g of graphene oxide and 3.0 g of L-cysteine and disperse them in 30 mL of 37% formaldehyde aqueous solution, and place them in an ultrasonic machine to disperse evenly and record as dispersion liquid A.

[0047] (2) Weigh 5.0g of melamine, 2.1g of sulfur powder and 10.0g of ammonium paramolybdate into 40mL of deionized water, and place it in an ultrasonic machine to disperse it uniformly and record it as dispersion B.

[0048] (3) Mix Dispersion A and Dispersion B, heat the water bath to 60°C and stir for 10min. Subsequently, triethanolamine was added to the reaction solution, the pH value of the reaction solution system was adjusted to 8.0, and the mixture was ultrasonically mixed evenly. The resulting solid was freeze-dried.

[0049] (4) The product obtained in step (3) was placed in a microwave reaction chamber, and 100 mL / min of argon was purged for 1 h. The nitrogen-doped molybdenum disulfide / three-dimensional graphene composite material was obtai...

Embodiment 3

[0051] (1) Weigh 1.0 g of graphene oxide and 4.0 g of L-cysteine and disperse them in 30 mL of 37% formaldehyde aqueous solution, and place them in an ultrasonic instrument to disperse evenly and record as dispersion liquid A.

[0052] (2) Weigh 10.0g of melamine, 1.2g of sulfur powder and 5.0g of sodium molybdate, add them into 40mL of deionized water, and place them in an ultrasonic machine to disperse them uniformly and record as dispersion B.

[0053] (3) Mix Dispersion A and Dispersion B, heat the water bath to 70°C and stir for 10min. Subsequently, triethanolamine was added to the reaction solution, the pH value of the reaction solution system was adjusted to 8.0, and the mixture was ultrasonically mixed evenly. The resulting solid was freeze-dried.

[0054] (4) The product obtained in step (3) was placed in a microwave reaction chamber, and 100 mL / min of argon was purged for 1 h. The nitrogen-doped molybdenum disulfide / three-dimensional graphene composite material w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com