Preparation method of m-xylene adsorbent

A m-xylene and adsorbent technology, which is applied in the field of m-xylene adsorbent preparation, can solve the problems of poor particle compressive strength, achieve high compressive strength, increase processing capacity, and prolong operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

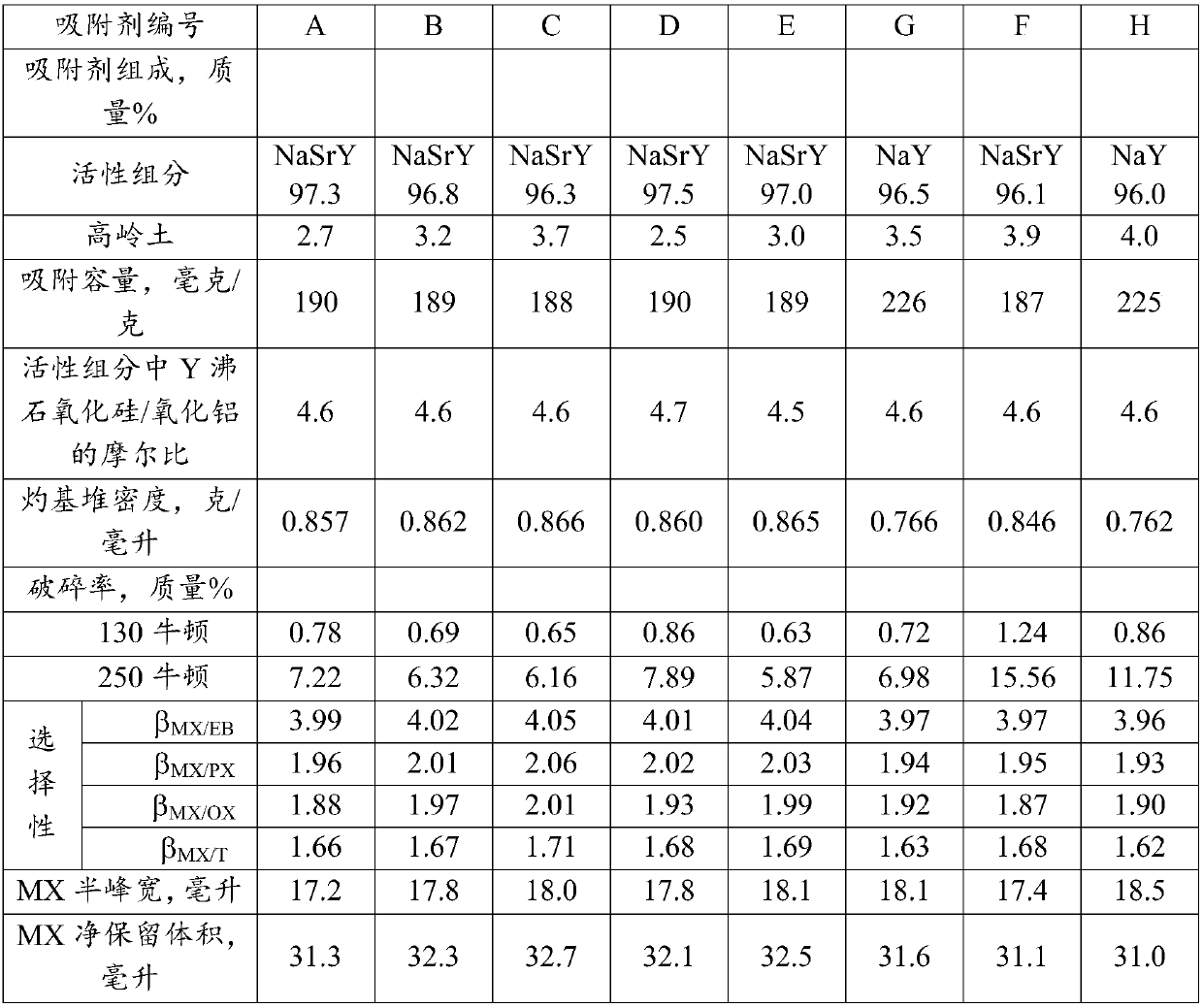

example 1

[0037] (1) Rolling ball forming

[0038] NaY zeolite and kaolin are mixed evenly according to the mass ratio of 95:5 to obtain the initial molding powder. The silica / alumina molar ratio of the NaY zeolite (toluene adsorption capacity is 234 mg / g) is 4.8, and the grain size is 1.0 to 1.5 microns, the average particle size of kaolin is 57 microns, which contains 80% by mass of kaolinite and 10% by mass of halloysite. Put the initial molding powder into the turntable and spray 10% of the powder while rolling. The mass % deionized water makes the powder aggregate into small balls for initial rolling ball forming. After the initial molding powder is all formed into balls, add the later molding powder to the rolling plate for later rolling ball molding. The later molding powder is composed of 16% by mass of kaolin and 84% by mass of NaY zeolite, during which the amount of water sprayed is 13% by mass of the molding powder; the late molding powder used is 4% of the mass of the initi...

example 2

[0043] The adsorbent was prepared according to the method of Example 1, except that the post-molding powder used was composed of 35% by mass of kaolin and 65% by mass of NaY zeolite. The composition and properties of the obtained adsorbent B are shown in Table 1.

example 3

[0045] The adsorbent was prepared according to the method of Example 1, except that the post-molding powder used was composed of 95% by mass of kaolin and 5% by mass of NaY zeolite. The composition and properties of the obtained adsorbent C were shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com