Synthetic method of p-acetoxystyrene

A technology of acetoxystyrene and acetoxybenzene, which is applied in the field of new preparation of p-acetoxystyrene, can solve the problems of large amount of wastewater that is difficult to treat, and achieve good application value, less three wastes and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

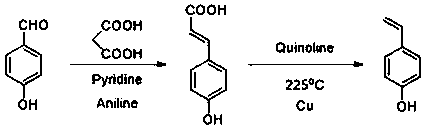

Method used

Image

Examples

Embodiment 1

[0024] In a three-necked flask, add 5.0g (0.028mol) of p-acetoxyphenylethanol, 5.0g of Hβ molecular sieve catalyst, 100mL of toluene and 0.05g of tert-butylcatechol, stir and react at 90 °C for 30 minutes, filter off the catalyst etc., spin-dried toluene, and rectified under reduced pressure to obtain 3.52 g of p-acetoxystyrene, and the yield was 78%. 1 H NMR (600 MHz, CDCl 3 ) δ7.51-7.43 (m, 2H), 7.16-7.07 (m, 2H), 6.82-6.68 (m, 1H), 5.76 (dd, J = 17.7,2.7 Hz, 1H), 5.29 (dd, J = 11.2, 2.6 Hz, 1H), 2.31 (s, 3H).

Embodiment 2

[0026] In a three-necked flask, add 5.0 g (0.028 mol) of p-acetoxyphenethyl alcohol, 5.0 g of H-ZSM-5 molecular sieve catalyst, 100 mL of toluene and 0.03 g of tert-butylcatechol, and stir the reaction at 90 °C for 30 Minutes, the catalyst was filtered off, the toluene was spin-dried, and rectified under reduced pressure to obtain 3.25 g of p-acetoxystyrene, with a yield of 72%.

Embodiment 3

[0028] In a three-necked flask, add 5.0 g (0.028 mol) of p-acetoxyphenethyl alcohol, 5.0 g of acidic alumina, and 100 mL of toluene, stir and react at 90 °C for 30 minutes, filter out the catalyst, spin dry the toluene, and purify under reduced pressure. Distillation gave 2.5 g of p-acetoxystyrene, and the yield was 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com