High-silicon aluminum alloy adapter plate and preparation method thereof

A high-silicon aluminum alloy and adapter plate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of low processing rate of through-holes, large restrictions on the shape and size of through-holes, and complicated procedures. , to achieve the effect of eliminating the metallization process of through holes, reducing the preparation time and cost, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

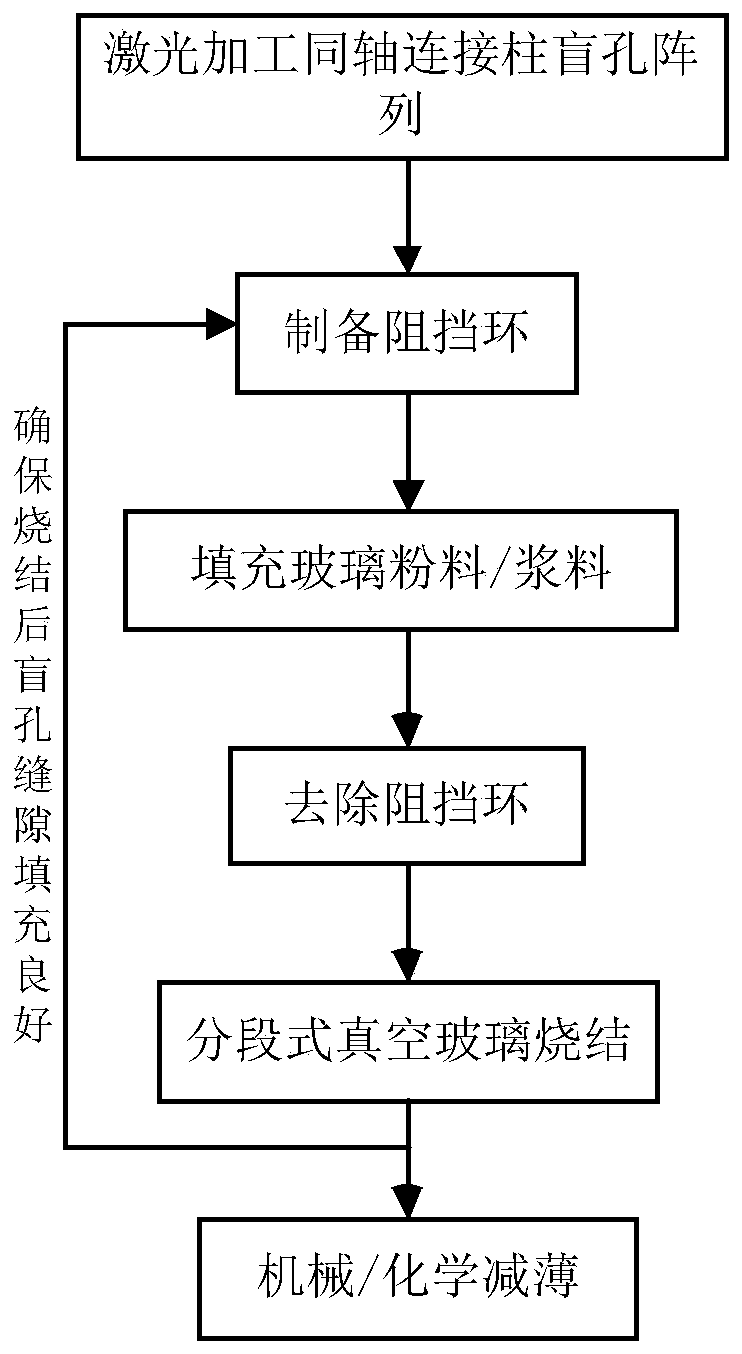

[0039] A high-silicon aluminum alloy adapter plate proposed by the present invention and its preparation method will be further described in detail below with reference to the accompanying drawings and specific examples. Advantages and features of the present invention will be apparent from the following description and claims.

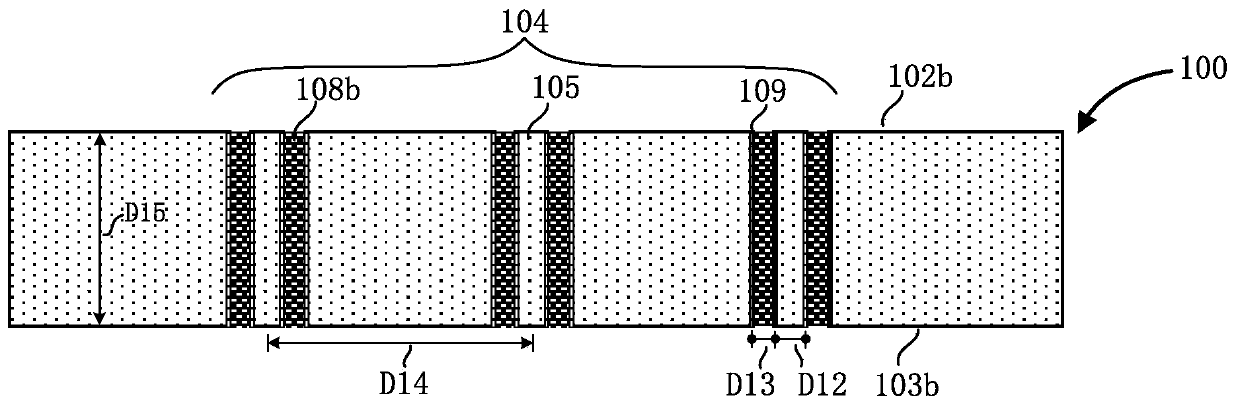

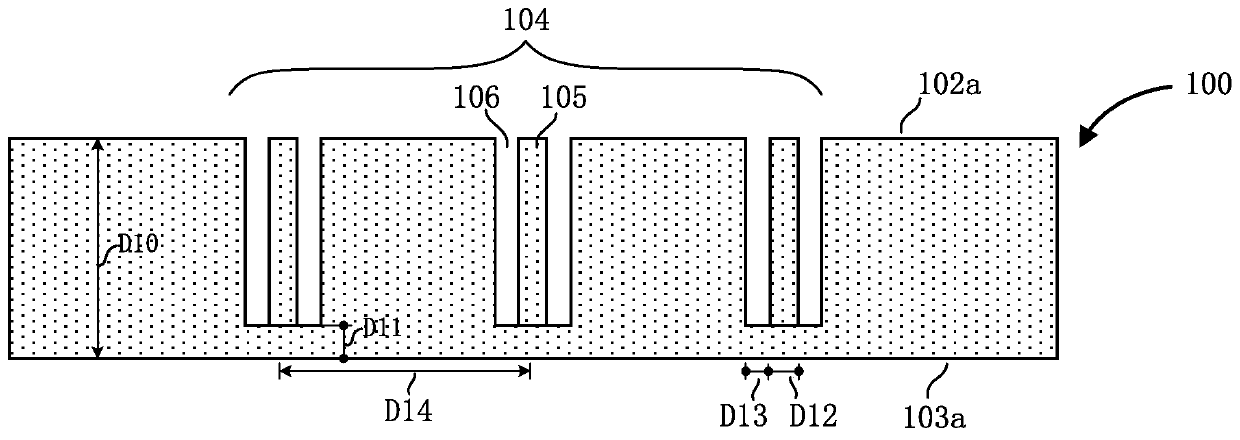

[0040] see figure 1, in one embodiment, a high-silicon aluminum alloy interposer, including a substrate 100, a connecting column array 104, and an insulating dielectric layer filled in the gap between the connecting column array 104 and the substrate 100, the connecting column array 104 is composed of the substrate 100 is processed by laser vertical through-hole technology, the substrate 100 and the connecting column array 104 are high-silicon aluminum alloy, the insulating medium layer is a glass medium 108b, the insulating medium layer is coaxial with the connecting column in the connecting column array, and the connecting column The array 104 , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com