Polypropylene compound with low linear expansion coefficient for automobile fender and preparation method thereof

A technology for automobile fenders and low linear expansion, which is applied in the field of polypropylene composites for automobile fenders with low linear expansion coefficient and its preparation, and can solve the problems of affecting the appearance of automobiles, large dimensional changes, and large linear expansion coefficients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

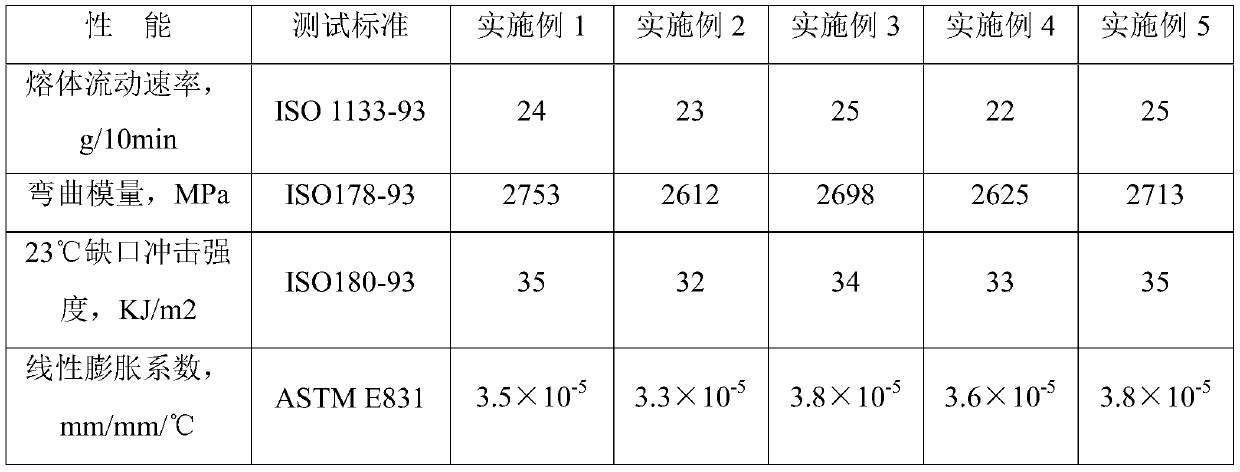

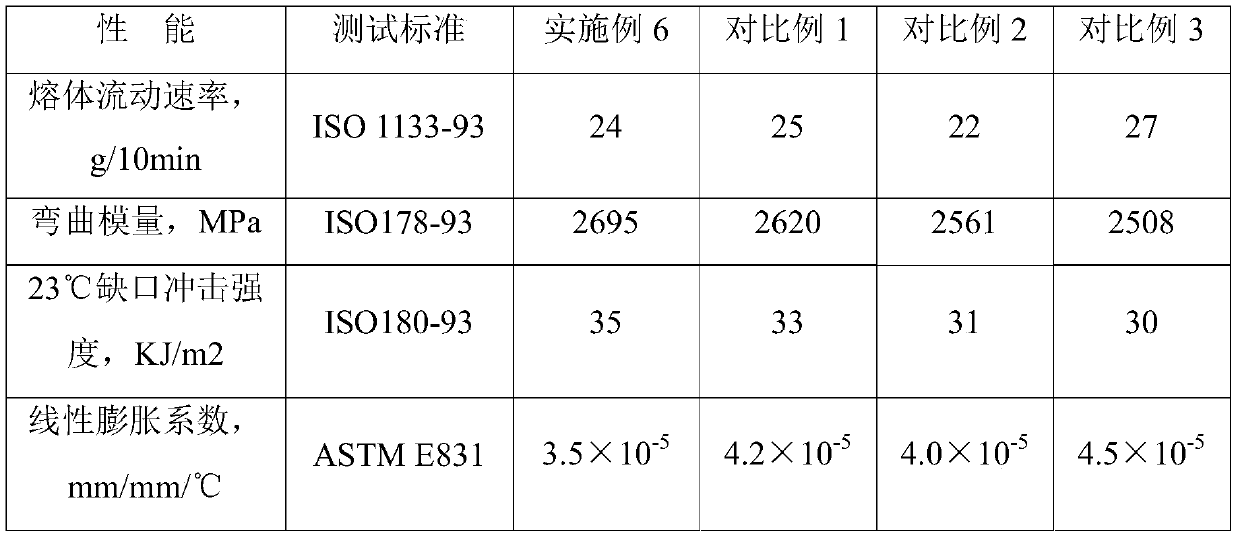

Examples

preparation example Construction

[0024] A method for preparing a polypropylene compound for a car fender with a low coefficient of linear expansion, the steps are as follows:

[0025] Step 1: Weigh the polypropylene, heat stabilizer, processing aid, ethylene / octene copolymer, hydrogenated styrene / butadiene / styrene copolymer and ethylene / acrylate copolymer in the aspect ratio of Melt mixing and dispersion in a 40:1 twin-screw extruder;

[0026] Step 2: Feed the superfine talc powder in the formulated amount into the twin-screw extruder from the side through the weight loss weighing scale, set the temperature of each section of the extruder at 190-240°C, extrude and granulate, and finally obtain the product.

[0027] One, the preparation of embodiment and comparative example

[0028] Polypropylene, manufacturer: SK Korea;

[0029] Phenolic heat stabilizer 1010, manufacturer: BASF;

[0030] Phosphite heat stabilizer, manufacturer: BASF;

[0031] Processing aid, manufacturer: Japan Kao;

[0032] Ethylene / oct...

Embodiment 1

[0037] 54 kg of polypropylene PP BX3900, 0.2 kg Phenols Thermal stability agent 1010, 0.3 kg of phosphite heat stabilizer 168, 0.5 kg of processing aid EBS (ethylene bis stearic acid amide), 5 kg of ethylene / octene copolymer POE 7447, 5 kg of hydrogenated styrene / butadiene / Styrene copolymer SEBS 6154, 5 kg of ethylene / acrylate copolymer EA101 are added to the extruder for melt mixing and dispersion; 30 kg of ultra-fine talc powder (5000 mesh) is accurately added from the side feeding through a weight-loss weighing scale, 200 ° C Extrude and granulate to finally get the product.

Embodiment 2

[0039] 51.5 kg of polypropylene PP BX3800, 0.5 kg Phenols Thermal stability agent1010, 0.5 kg of phosphite heat stabilizer 168, 0.5 kg of processing aid EB-FF, 6 kg of ethylene / octene copolymer POE 8137, 3 kg of hydrogenated styrene / butadiene / styrene copolymer SEBS G1657, 3 kg of ethylene / acrylate copolymer EMA 1125C is melt-mixed and dispersed in a twin-screw extruder with an aspect ratio of 1:40; 35 kg of superfine talc powder (8000 mesh) is accurately fed from the side through a loss-in-weight weighing scale Add, extrude and granulate at 220°C, and finally get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com