Lithium iron phosphate battery and preparation method thereof

A technology of lithium iron phosphate battery and lithium iron phosphate, which is applied in secondary battery manufacturing, electrolyte storage battery manufacturing, secondary battery, etc., can solve the problems of poor wettability between high-density electrode sheets and electrolyte, and achieve normal temperature and high temperature Improve cycle performance, prolong service life, solve the effect of poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

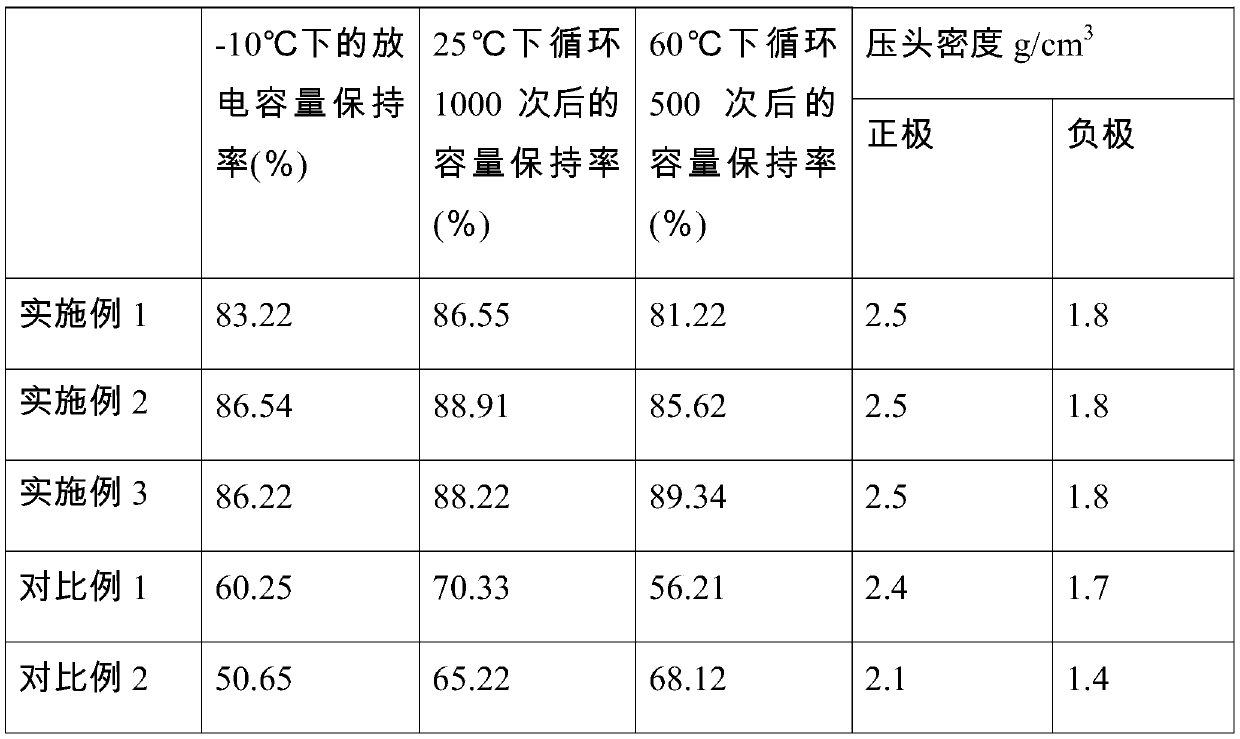

Examples

Embodiment 1

[0020] In this example lithium iron phosphate battery, the positive electrode material includes the following components: 2 parts of lithium iron phosphate, 5 parts of conductive agent, 1 part of binder, and 2.5 parts of carbon nanotube slurry; the negative electrode material contains the following parts by weight Components: 1 part of graphite carbon black, 5 parts of conductive agent, 1 part of adhesive, 0.8 part of fullerene, 5 parts of nanowire, 2 parts of nano titanium, the mass fraction of catechol diacetate 5%.

[0021] The preparation method of the lithium iron phosphate battery of this embodiment comprises the following steps:

[0022] (1) Ingredients: mix lithium iron phosphate, conductive agent, binder, and carbon nanotube slurry to obtain mixed positive electrode slurry; mix graphite carbon black, conductive agent, binder, fullerene, nanowire, nano Titanium is mixed to obtain a mixed negative electrode slurry;

[0023] (2) coating: the above-mentioned positive el...

Embodiment 2

[0032] In this example lithium iron phosphate battery, the positive electrode material comprises the following components: 10 parts of lithium iron phosphate, 30 parts of conductive agent, 15 parts of binder, and 30 parts of carbon nanotube slurry; the negative electrode material comprises the following parts by weight Components: 20 parts of graphite carbon black, 30 parts of conductive agent, 15 parts of binder, 25 parts of fullerene, 15 parts of nanowire, 8 parts of nano titanium, the mass fraction of catechol diacetate 12%.

[0033] The preparation method of the lithium iron phosphate battery of this embodiment adopts the same preparation method as that of Example 1.

[0034] The method for extracting fullerenes in this embodiment adopts the same extraction method as in Example 1.

[0035] The preparation method of electrolyte in the present embodiment is:

[0036] The organic solvent ethyl methyl carbonate, dimethyl carbonate, and methyl propionate were mixed, and final...

Embodiment 3

[0039] In this example lithium iron phosphate battery, the positive electrode material comprises the following components: 7 parts of lithium iron phosphate, 15 parts of conductive agent, 7 parts of binder, and 15 parts of carbon nanotube slurry; the negative electrode material comprises the following parts by weight Components: 10 parts of graphite carbon black, 15 parts of conductive agent, 8 parts of binder, 12 parts of fullerene, 10 parts of nanowire, 5 parts of nano titanium, the mass fraction of catechol diacetate 10%.

[0040] The preparation method of the lithium iron phosphate battery of this embodiment adopts the same preparation method as that of Example 1.

[0041] The extraction method of fullerene in this embodiment adopts the same extraction method as that of Example 1.

[0042] The preparation method of the negative electrode material in this example adopts the same preparation method as that of Example 1.

[0043] The preparation method of electrolyte in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com