Preparation method of hollow mesoporous silica\APS\graphene oxide nano container

A mesoporous silica, \APS\ technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problem of unsatisfactory corrosion resistance of coatings, reduced corrosion resistance of organic coatings, and poor dispersion. To achieve the effect of long-term corrosion protection, improve dispersion and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

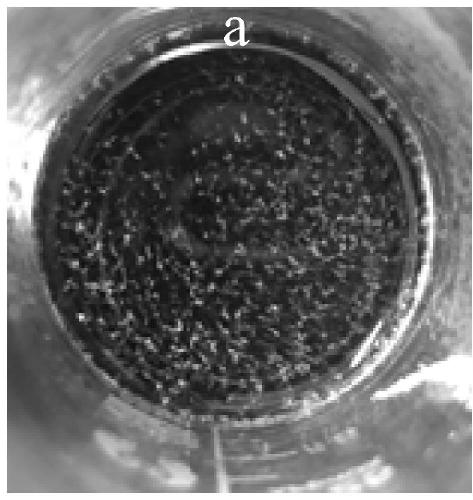

Image

Examples

Embodiment 1

[0029] (1) Weigh 1 g of cetyltrimethylammonium bromide (CTAB) and add it into a mixed solution of 110 mL of ethanol and 10 mL of water and stir evenly. Add 2 mL of copolymer microsphere template solution to the mixed solution, and sonicate for 10 minutes. The resulting solution was transferred to a 250 mL three-neck flask, and stirred in a water bath at 50° C. for 1 hour. The pH of the solution was adjusted to alkaline by adding 6 mL of ammonia water, and stirring was continued for 10 minutes. Then, 3 mL of tetraethyl orthosilicate (TEOS) was added, and the temperature was kept constant, and stirring was continued for 6 hours to complete the reaction. The resulting slurry was centrifuged at a rotational speed of 4000r / min, and the supernatant was removed. The precipitate was washed three times with water and ethanol, then dried in vacuum at 60°C for 24 hours, and the resulting product was calcined in a muffle furnace at 550°C for 3 hours to remove the microsphere template an...

Embodiment 2

[0034] (1) Weigh 0.5 g of cetyltrimethylammonium bromide (CTAB) and add it into a mixed solution of 55 mL of ethanol and 5 mL of water and stir evenly. Add 1 mL of copolymer microsphere template solution to the mixed solution, and sonicate for 15 minutes. The resulting solution was transferred to a 100 mL three-necked flask, and stirred in a water bath at 55° C. for 1.5 hours. The pH of the solution was adjusted to alkaline by adding 3 mL of ammonia water, and stirring was continued for 15 minutes. Then, 1.5 mL of tetraethyl orthosilicate (TEOS) was added, and the temperature was kept constant, and stirring was continued for 7 hours to complete the reaction. The resulting slurry was centrifuged at a rotational speed of 4000r / min, and the supernatant was removed. The precipitate was washed three times with water and ethanol, and then vacuum-dried at 60°C for 25 hours, and the resulting product was calcined in a muffle furnace at 550°C for 4 hours to remove the microsphere tem...

Embodiment 3

[0039] (1) Weigh 1 g of cetyltrimethylammonium bromide (CTAB) and add it into a mixed solution of 110 mL of ethanol and 10 mL of water and stir evenly. Add 2 mL of copolymer microsphere template solution to the mixed solution, and sonicate for 15 minutes. The resulting solution was transferred to a 250 mL three-necked flask, and stirred in a water bath at 60° C. for 1 hour. The pH of the solution was adjusted to alkaline by adding 6 mL of ammonia water, and stirring was continued for 10 minutes. Then, 3 mL of tetraethyl orthosilicate (TEOS) was added, and the temperature was kept constant, and stirring was continued for 6 hours to complete the reaction. The resulting slurry was centrifuged at a rotational speed of 4000r / min, and the supernatant was removed. The precipitate was washed three times with water and ethanol, and then vacuum-dried at 60°C for 24 hours, and the resulting product was calcined in a muffle furnace at 550°C for 5 hours to remove the microsphere template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com