High-strength Mo-Hf-CNT molybdenum-based composite material and a preparation method thereof

A composite material, mo-hf-cnt technology, applied in the field of high-strength Mo-Hf-CNT molybdenum-based composite material and its preparation, can solve the problems of low strength and small quantity of MHC alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the Mo-Hf-CNT molybdenum-based composite material in this embodiment, carbon nanotubes are used as the carbon source, and the components are constituted by mass percentage: Hf 1.2%, CNT 0.1%, and the balance is Mo.

[0024] The original powder particle size is: HfH 2 The particle size of the powder is 3-5 microns, the outer diameter of the multi-walled CNT powder is greater than 50 nanometers, the inner diameter is 5-15 nanometers, and the length is 0.5-2 microns, and the particle size of the Mo powder is 3-5 microns.

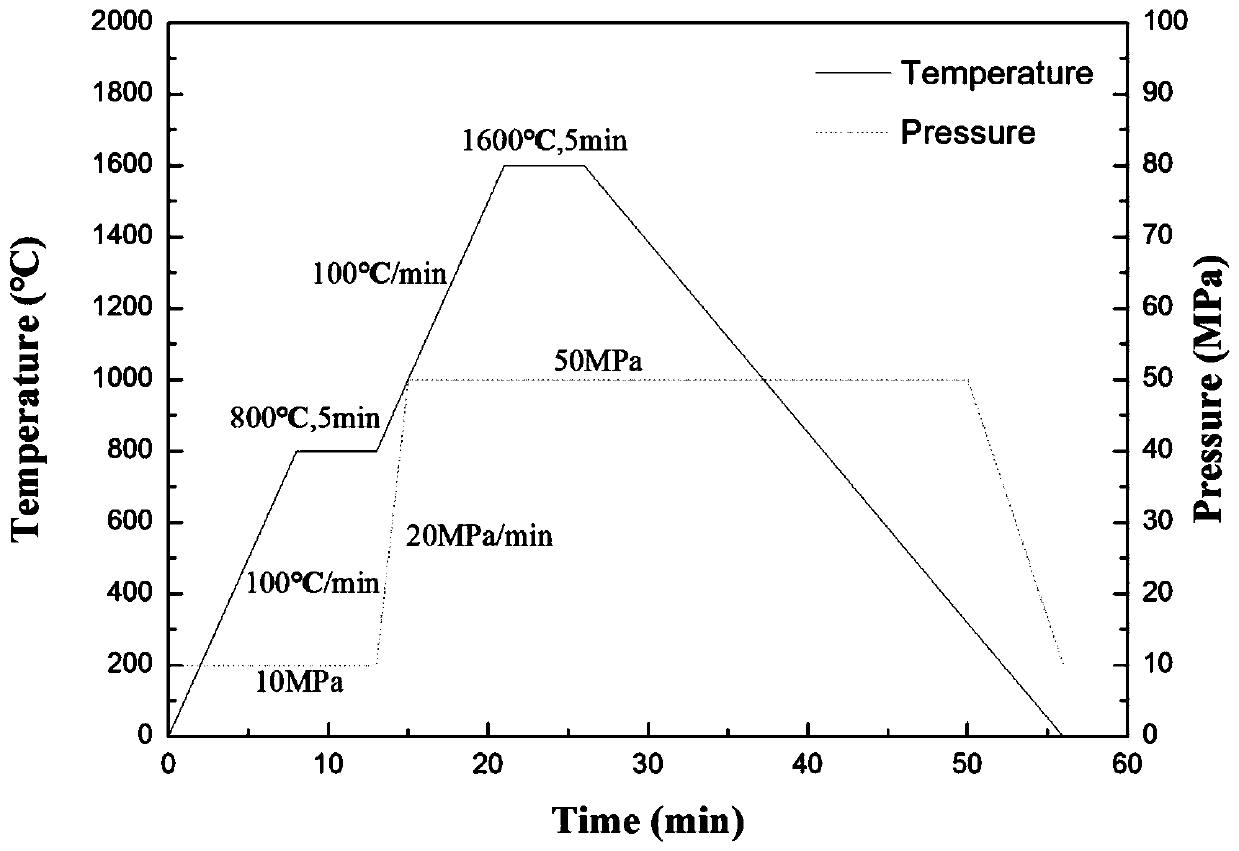

[0025] The preparation method of high-strength Mo-Hf-CNT molybdenum-based composite material in the present embodiment comprises the following steps:

[0026] 1. Mix powder in liquid phase: weigh 0.6g HfH according to the proportion 2 powder and 0.05g CNT powder were placed in a beaker with 200ml of alcohol and heated to 50°C. Ultrasonic stirring was required while the CNT powder was being heated for 2 hours. The solutions were named A and B respecti...

Embodiment 2

[0031] In the Mo-Hf-CNT molybdenum-based composite material in this embodiment, carbon nanotubes are used as the carbon source, and the components are constituted by mass percentage: Hf 1.2%, CNT 0.1%, and the balance is Mo.

[0032] The original powder particle size is: HfH 2 The particle size of the powder is 3-5 microns, the outer diameter of the multi-walled CNT powder is greater than 50 nanometers, the inner diameter is 5-15 nanometers, and the length is 0.5-2 microns, and the particle size of the Mo powder is 3-5 microns.

[0033] The preparation method of high-strength Mo-Hf-CNT molybdenum-based composite material in the present embodiment comprises the following steps:

[0034] 1. Mix powder in liquid phase: weigh 0.6g HfH according to the proportion 2 powder and 0.05g CNT powder were placed in beakers filled with 200ml of alcohol and heated to 50°C. Ultrasonic stirring was required while the CNT powder was heating for 2 hours. The solutions were named A and B respect...

Embodiment 3

[0039] In the Mo-Hf-CNT molybdenum-based composite material in this embodiment, carbon nanotubes are used as the carbon source, and the components are constituted by mass percentage: Hf 1.2%, CNT 0.1%, and the balance is Mo.

[0040] The original powder particle size is: HfH 2 The particle size of the powder is 3-5 microns, the outer diameter of the multi-walled CNT powder is greater than 50 nanometers, the inner diameter is 5-15 nanometers, and the length is 0.5-2 microns, and the particle size of the Mo powder is 3-5 microns.

[0041] The preparation method of high-strength Mo-Hf-CNT molybdenum-based composite material in the present embodiment comprises the following steps:

[0042] 1. Mix powder in liquid phase: weigh 0.36g HfH according to the proportion 2 powder and 0.03g CNT powder were placed in beakers filled with 200ml of alcohol and heated to 50°C. Ultrasonic stirring was required while the CNT powder was heating for 2 hours. The solutions were named A and B respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com