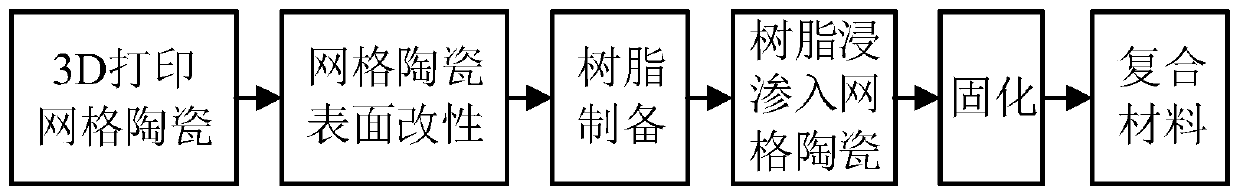

3D printed grid ceramic reinforced resin composite material and preparation method thereof

A composite material and reinforced resin technology, which is applied in the production of ceramic materials, ceramic products, additive processing, etc., can solve problems such as excessive wear, fatigue damage, warping and deformation, achieve low cost, easy porosity, and improve reliability and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

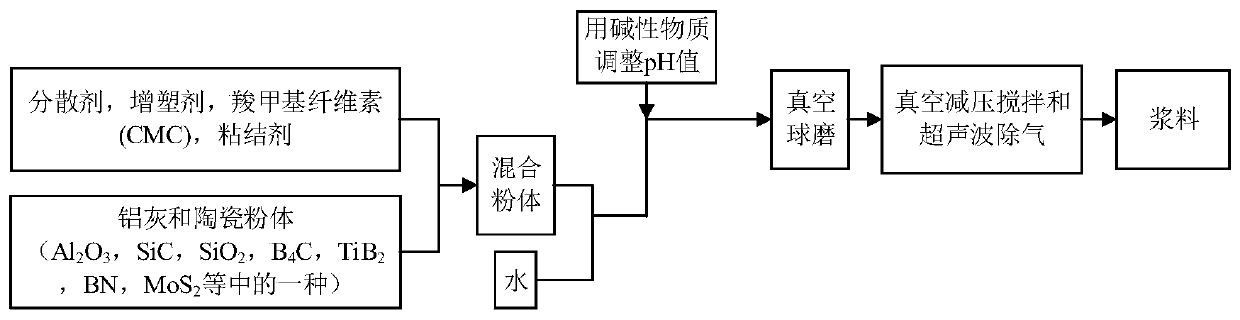

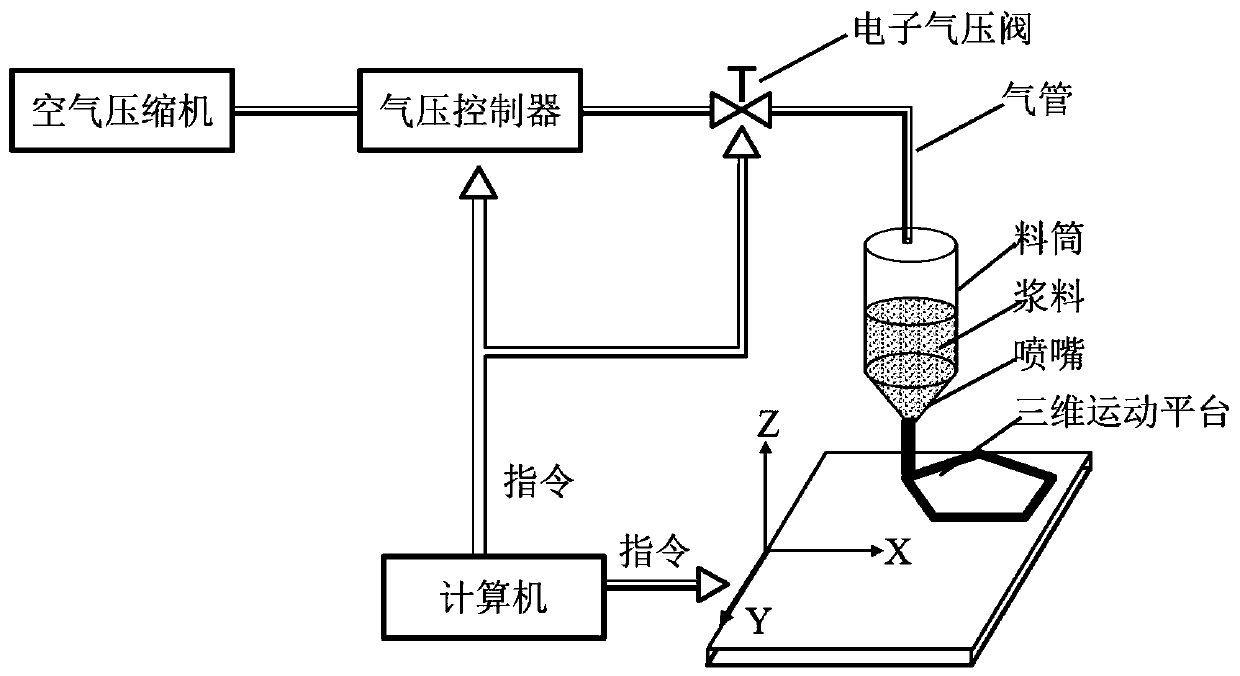

[0049] Specific embodiment one, the preparation method of 3D printing aluminum ash-MgO grid ceramics reinforced epoxy resin composite material;

[0050] S1: Preparation of aluminum ash-MgO grid ceramics and surface modification

[0051] (S1-a) Calculated by weight of 100g, 80g of aluminum ash, 20g of powdered MgO, 0.5g of carboxymethyl cellulose (CMC), 1g of dispersant (DOLAPIX SPC7), 1g of plasticizer (ZUSOPLAST PS1), binder ( Water-soluble polyvinyl alcohol) 0.5g as the raw material, weighed, mechanically stirred and mixed evenly, placed in a planetary ball mill, then added 100ml of water, added alkaline substances, adjusted the pH value of the slurry to 12, high-speed ball milled for 15 minutes, and formed Uniform slurry. Smelting, aging, and vacuuming in the mud mixer to make clay for later use; put the clay into the squeeze barrel, and use 3D printing to extrude through the mud nozzle, and the mud nozzle cooperates with the movement to make the mud strips reciprocally in...

specific Embodiment 2

[0069] Specific embodiment two, the preparation method of 3D printing aluminum ash-SiC mesh ceramic reinforced polyester composite material:

[0070] S1: Preparation of aluminum ash-SiC grid ceramics and surface modification;

[0071] (S1-a) Based on the weight of 100g, 85g of aluminum ash, 15g of SiC powder, 0.5g of carboxymethyl cellulose (CMC), 1g of dispersant (DOLAPIX SPC7), 1g of plasticizer (ZUSOPLAST PS1), binder (Water-soluble polyvinyl alcohol) 0.5g as raw material, after weighing, mechanically stir and mix evenly, put it in a ball mill, then add 100ml of water, add alkaline substances, adjust the pH value of the slurry to 12, and high-speed ball mill for 10-15 minutes , forming a homogeneous slurry. Refining and maturing in the mud mill for 2 days, vacuuming to make clay for later use; put the clay into the extrusion barrel, use 3D printing to extrude through the mud nozzle, and the mud nozzle cooperates with the movement to make the mud strips interweave and recip...

specific Embodiment 3

[0085] Specific embodiment three, 3D printing aluminum ash-TiO 2 Preparation method of mesh ceramic reinforced phenolic resin composite:

[0086] S1: Preparation of aluminum ash-TiO 2 Fabrication and Surface Modification of Mesh Ceramics

[0087] (S1-a) Calculated by weight of 100g, 80g of aluminum ash, TiO 2 (Titanium dioxide) powder 20g, carboxymethylcellulose (CMC) 0.5g, dispersant (DOLAPIX SPC7) 1g, plasticizer (ZUSOPLAST PS1) 1g, binder (water-soluble polyvinyl alcohol) 0.5g as raw materials, After weighing, mechanically stir and mix evenly, place in a ball mill, add 100ml of water, add alkaline substances, adjust the pH value of the slurry to 12, and perform high-speed ball milling for 15 minutes to form a uniform slurry. Refining and maturing for 1 day in the clay refiner, then vacuumize to make clay for later use; put the clay into the extrusion barrel, use 3D printing to extrude through the mud nozzle, and the mud nozzle cooperates with the movement to make the mud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com