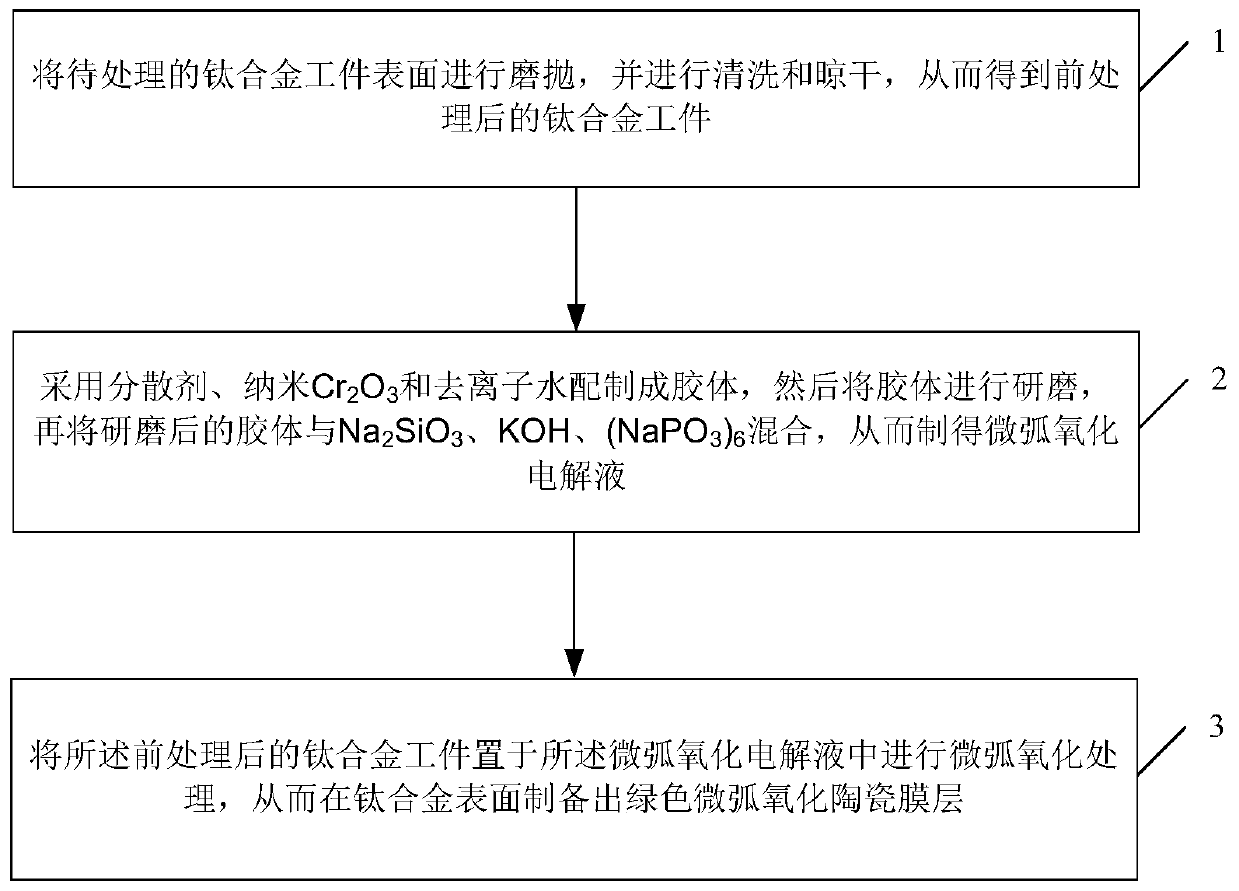

Method for preparing green micro-arc oxidation ceramic film layer on surface of titanium alloy

A technology of micro-arc oxidation and ceramic film layer, which is applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of poor bonding force and unsatisfactory coloring effect, and achieve strong film/substrate bonding force and excellent Good wear and corrosion resistance and color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] (1) The titanium alloy workpiece to be processed is TC4 titanium alloy or TC10 titanium alloy. In practical applications, the titanium alloy workpiece to be processed may be: a disc with a diameter of 30 mm and a thickness of 3 mm.

[0026] (2) The process parameters used in the micro-arc oxidation treatment are: under constant current mode, the forward current density is 6-14A / dm 2 , The negative current density is 1~6A / dm 2 , The frequency is 400Hz-1000Hz, the positive duty ratio is 30%-70%, the negative duty ratio is 10%-30%, and the time is 5-20min. In practical applications, the electrolytic cell used in the micro-arc oxidation treatment is connected to an ultrasonic power supply, and is equipped with a stirring and cooling device.

[0027] Furthermore, the method for preparing green micro-arc oxidation ceramic film on the surface of titanium alloy provided by the present invention adopts specific process parameters for micro-arc oxidation treatment. Under the ac...

Embodiment 1

[0031] A method for preparing a green micro-arc oxidation ceramic film layer on the surface of a titanium alloy, comprising the steps of:

[0032] Step A. Polish the surface of the TC4 titanium alloy workpiece to be treated on 180#, 400#, 800# and 1200# silicon carbide sandpaper in sequence, and polish it with a polishing cloth to achieve a mirror effect, and then use deionized water and anhydrous water respectively Ethanol is used for ultrasonic cleaning and drying to obtain pretreated titanium alloy workpieces.

[0033] Step B, adopt 5g sodium polyacrylate (as dispersant), 40g nano-Cr 2 o 3 (as coloring agent) and deionized water are mixed with 400mL colloid, then described colloid is placed in the plastic tank and adopts the alumina ball of 6mm to carry out the grinding of 36 hours, then the colloid after grinding and the Na of 25g 2 SiO 3 , 5g of KOH, 5g of (NaPO 3 ) 6 Mix, and add deionized water to make the final volume of the solution 5L, stir evenly, so that the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com