An integrated heat treatment process combining homogenization and heating and aluminum alloy ingot casting

A homogeneous heat treatment and aluminum alloy ingot casting technology, which is applied in the field of aluminum alloy materials, can solve problems such as surface defects and low gloss of mirror aluminum alloys, and achieve the effects of increased product qualification rate, reduced manufacturing cost, and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1, the 8014 mirror aluminum alloy ingot is subjected to an integrated heat treatment of homogenization and heating, the process steps and parameters are as follows:

[0027] (1) Homogenization heat treatment: Slowly raise the temperature of the aluminum alloy ingot to 630°C, the heating rate is 30°C / h, and then heat preservation treatment for 16h;

[0028] (2) Heating heat treatment: the aluminum alloy ingot after homogenization heat treatment is cooled to 500°C, and then kept for 10 hours.

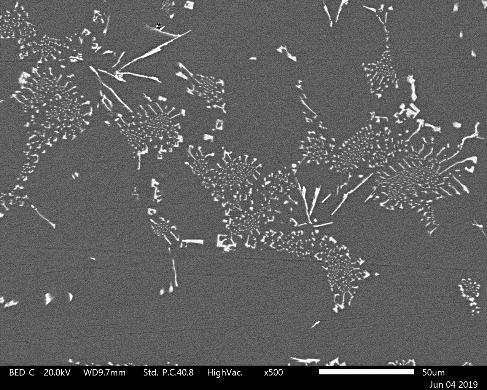

[0029] After the integrated heat treatment of homogenization and heating, the distribution of the second phase in the 8014 mirror aluminum alloy ingot is as follows: figure 2 shown. Compared with the 8014 mirror aluminum alloy ingot without heat treatment, the number of Fe-containing second phases (diameter > 0.5 μm) in the aluminum alloy ingot treated by the process described in this example is 707, and the area ratio is 1.10 %; the Fe-containing second phase is spheric...

Embodiment 2

[0030] Example 2, the 8014 mirror aluminum alloy ingot is subjected to an integrated heat treatment of homogenization and heating, the process steps and parameters are as follows:

[0031] (1) Homogenization heat treatment: Slowly raise the temperature of the aluminum alloy ingot to 610°C, the heating rate is 30°C / h, and then heat preservation treatment for 10h;

[0032] (2) Heating heat treatment: the aluminum alloy ingot after homogenization heat treatment is cooled to 510°C, and then kept for 4 hours.

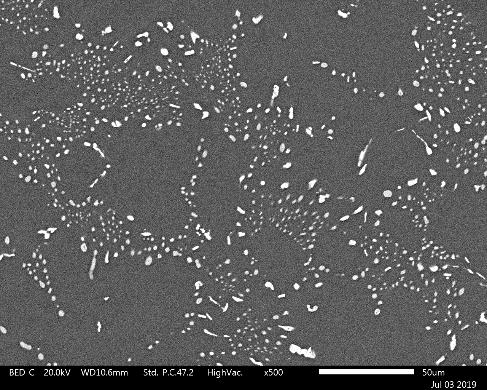

[0033] After the homogenization and heating integrated process, the distribution of the second phase in the 8014 mirror aluminum alloy ingot is as follows: image 3 shown. Compared with the 8014 mirror aluminum alloy ingot without heat treatment, after the process described in this example, the number of Fe-containing second phases (diameter > 0.5 μm) in the aluminum alloy ingot is 410, and the area ratio is 0.64 %; the Fe-containing second phase is spherical and dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com