A water-based wear-resistant super amphiphobic nanocomposite coating and its preparation method

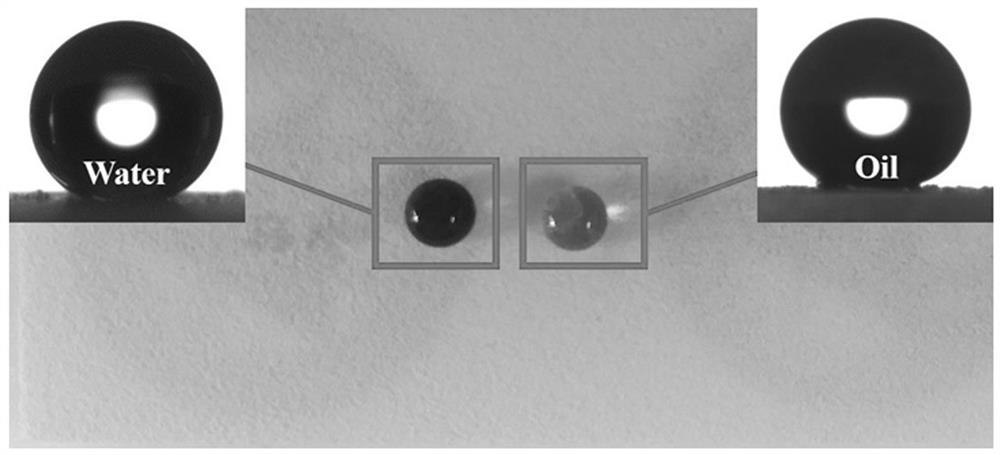

A nano-composite coating, super-amphiphobic technology, applied in coatings, fire-retardant coatings, polyurea/polyurethane coatings, etc. layer roughness, enhanced superoleophobic effect, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

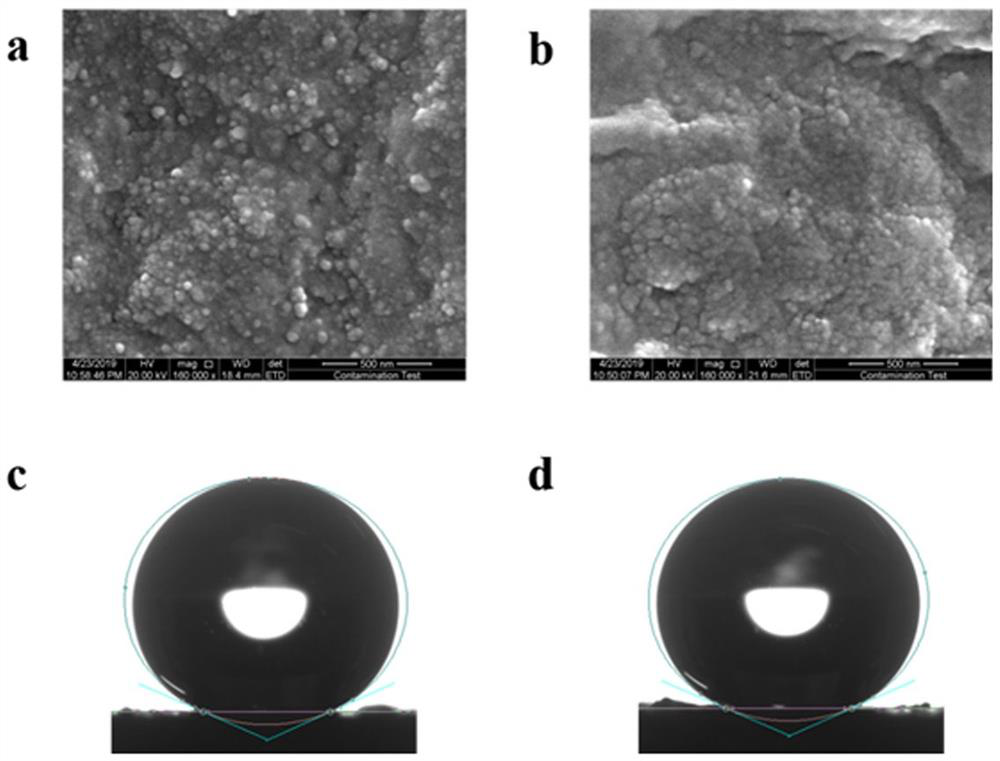

[0022] (1) Ultrafiltration amphiphobic silica nanoparticles Powder: A mixture of 6 parts of aqueous ammonia solution is dispersed in 80 parts of absolute ethanol, at a rotation speed 200rpm conditions, stirred at 50 ℃ 4min, followed by addition of 10 parts of compound silica, stirring was continued for 10min after addition of 0.2 parts of tetraethyl orthosilicate, stirring was continued for 30min, was added 0.2 parts of tridecafluorooctyl trimethoxysilane, stirring 2h placed on a rotary evaporator, rotated at 60 ℃ evaporated 60min, then placed over the particles hydrophobic silica nanoparticles bis powder freeze drier -80 ℃ freeze dried 6 h, can be obtained;

[0023] Preparation of nanocomposite amphiphobic coating (2) over an aqueous wear resistant: 1 parts of the hydrophobic silica particles are ultra-bis powder dispersed in a heterogeneous parts hexadecane at a rotation speed 200rpm conditions, 4min at room temperature with stirring, followed by after addition of 15 parts of de...

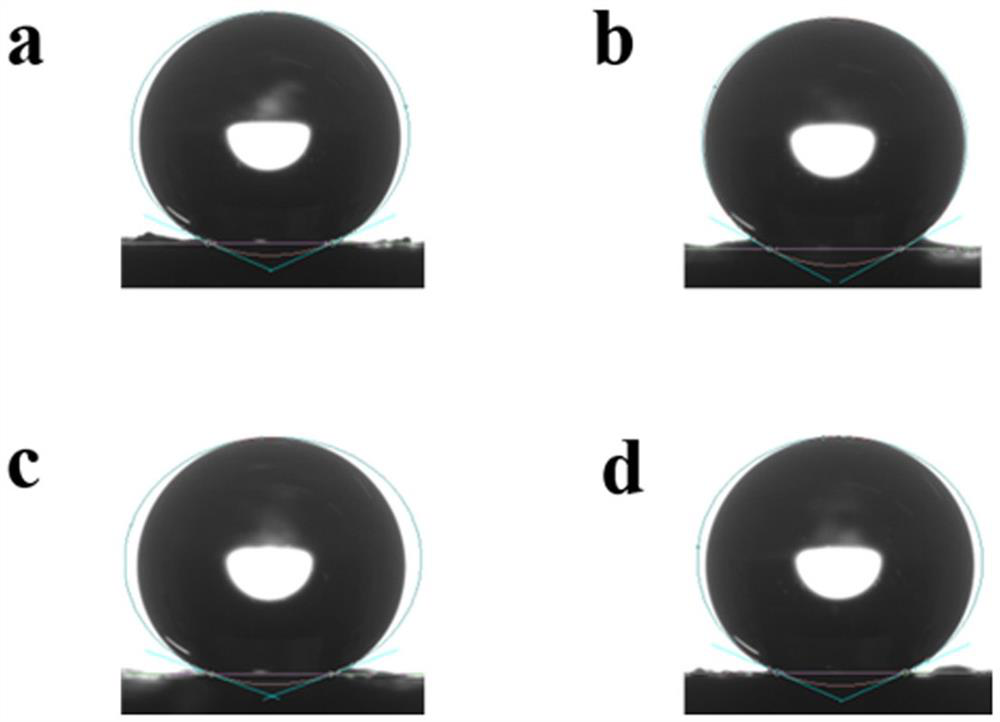

Embodiment 2

[0027](1) Preparation of superbish silica nanoparticle powder: 6 parts of aqueous ammonia solution was dispersed in 80 parts of anhydrous ethanol solution, and at a speed of 200 rpm, stirred at 50 ° C for 4min, then add 10 copies. Silica sol, followed by stirring for 10 min, add 0.2 parts of n-ethyl silicate, continued for 30 min, add 0.2 parts of thirtexluoromethyltrimethoxysilane, and stirred in a rotary evaporator after stirring, rotate at 60 ° C. 60 min was evaporated, then the particles were placed in a freeze dryer - 80 ° C for 6 h, that is, ultra-double silica nanoparticle powder is obtained;

[0028] (2) Preparation of aqueous abrasion-resistant ultrachoxienm composite coating: 1 part of the superblicit silica particulate powder is dispersed in 1 parts of air kerosene, and at a speed of 200 rpm, the mixture is stirred at room temperature for 4 min, then add 20 parts. Deionized water, then add 0.1 parts of aqueous anionic fluorocarbon surfactant, stirred for 10 min, add 2 p...

Embodiment 3

[0032] (1) Preparation of superbish silica nanoparticle powder: 6 parts of aqueous ammonia solution was dispersed in 80 parts of anhydrous ethanol solution, and at a speed of 200 rpm, stirred at 50 ° C for 4min, then add 10 copies. Silica sol, continued to stir after 10min and add tetraeth ester, continued to stir for 30 min, add 0.2 parts of hexadalkyltrimethoxysilane, stir for 2 h, was placed in a rotary evaporator, rotate under 60 ° C. Evaporation 60min, then place the particles in a freeze dryer - 80 ° C for 6 h, to obtain ultra-double silica nanoparticle powder;

[0033] (2) Preparation of aqueous abrasion-resistant superbrochrometric composite coating: 1 part of the superblicic silica particulate powder was dispersed in 1 part of heterozose, and at a speed of 200 rpm, stirred at room temperature for 4 min, then 15 parts of deionized water were added, and then 0.1 parts aqueous anionic fluorocarbon surfactant was added, and 1.5 parts of water-based melamine formaldehyde resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com