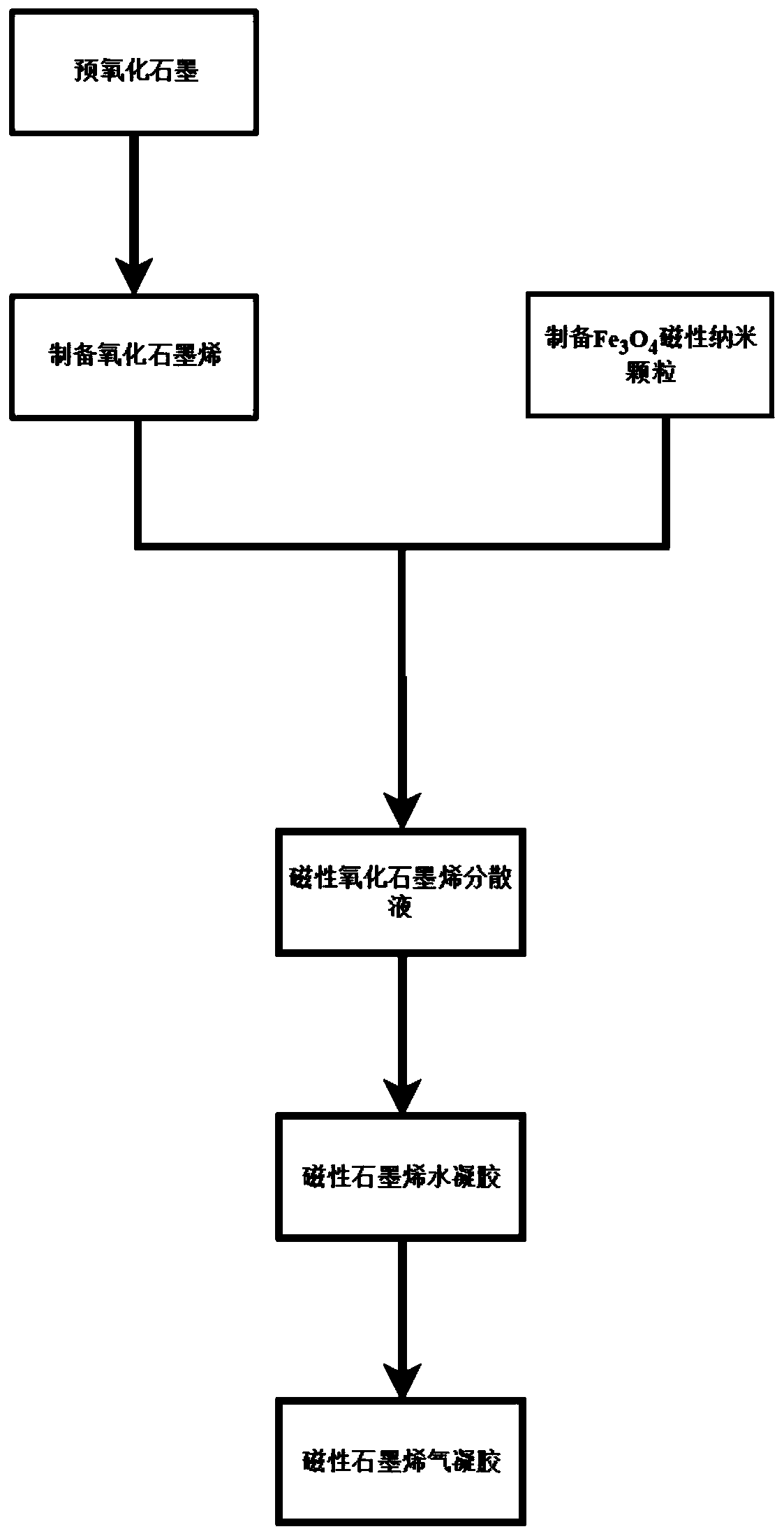

Preparation method of graphene magnetic aerogel with high adsorption performance

A technology of graphene and aerogel, which is applied in the field of preparation of graphene magnetic aerogel with high adsorption performance, can solve the problems of impurity ions, loss of graphene oxide materials, etc., achieve high adsorption capacity, improve microstructure and specificity Surface area, the effect of high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

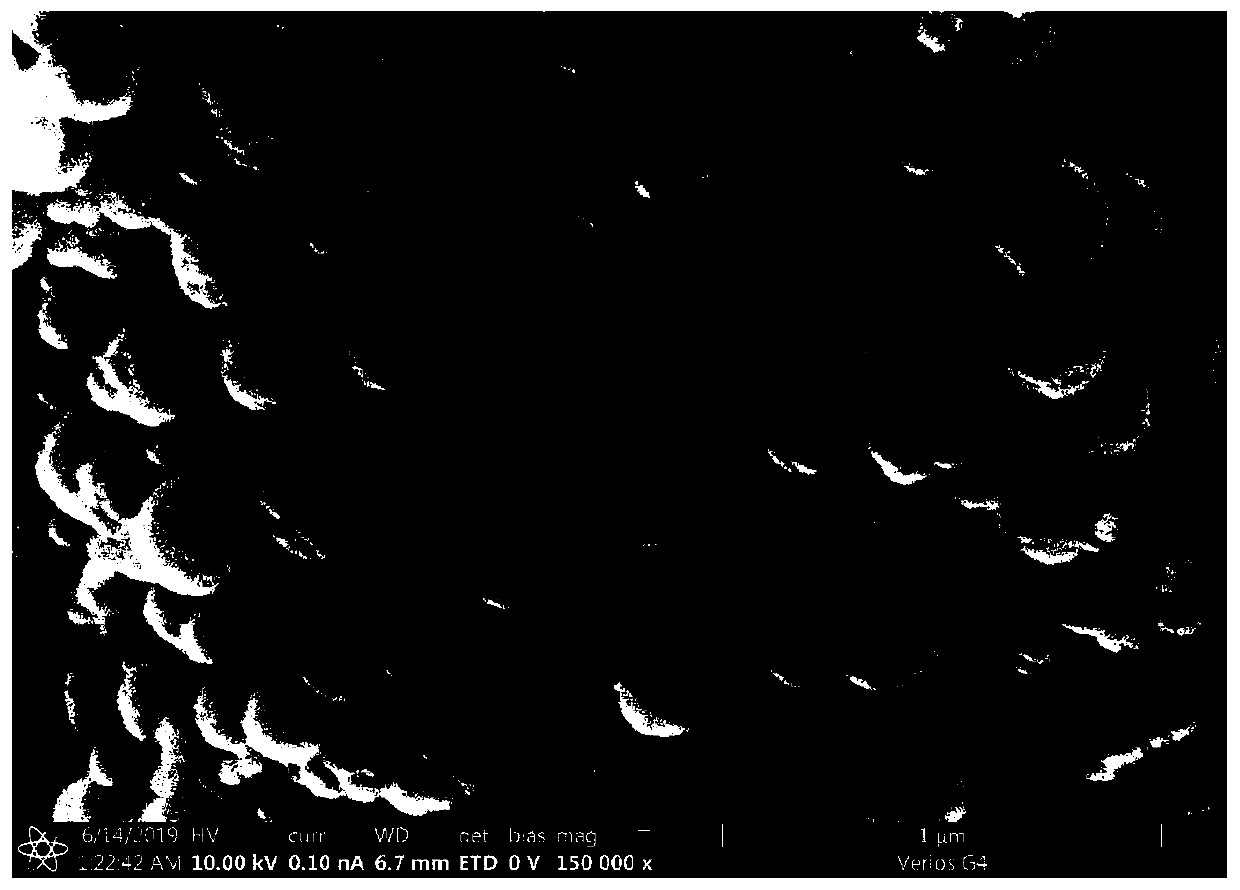

[0039] (2) Preparation and purification of graphene oxide: the pre-oxidized graphite and sodium nitrate obtained in step (1) are fully mixed with concentrated sulfuric acid in a reaction vessel in a mass ratio of (0.1~1):(0.1~1) , and then kept stirring at 0-8°C for 10-60 minutes. After mixing evenly, add potassium permanganate with a mass ratio of (1-6):(0.1-1) to the pre-oxidized graphene to react for 20-100 minutes, then raise the temperature to 30-60°C to continue the reaction for 10-100 minutes, add 50 ~150 mL deionized water. Then continue to heat up to 80-100°C, keep stirring for 10-40min, and when the reaction solution is cooled to room temperature, add 150-300mL deionized water and 1-10ml 30% hydrogen peroxide solution to obtain a golden yellow graphene oxide solution. Filter the obtained graphene oxide solution, and wash with deionized water and 5%-10% hydrochloric acid for 2-7 times. Finally, the washed product was centrifuged 2 to 7 times under the condition of 1...

Embodiment 1

[0050] The graphite powder was pre-oxidized and the resulting graphene oxide solution was purified by dialysis.

[0051] (1) Take respectively graphite powder (particle diameter is 50~150 μm), concentrated nitric acid, concentrated sulfuric acid and potassium permanganate, with mass ratio (0.5~2):(0.5~2):(0.2~1.5):( 0.2 to 1.5) into the reaction vessel, stirred and mixed to obtain a dark brown viscous liquid. Subsequently, wash the viscous liquid with water (to PH = 6.8-7.2) and dry (dry at a temperature of 50-90°C for 10-20h), and then immediately put the dried sample into a crucible with a temperature of 800-1000°C , cover the crucible lid, and obtain the expanded graphite sample when the crucible is cooled to room temperature. Then get expanded graphite, potassium persulfate and phosphorus pentoxide, in the ratio of (1~5):(1~4):(1~4) in mass ratio in the concentrated sulfuric acid of 80 ℃ and insulate and stir for 1~8h, Then the solution is washed with water so that the p...

Embodiment 2

[0063] The graphite powder was pre-oxidized, and the resulting graphene oxide solution was not purified by dialysis.

[0064] (1) Take respectively graphite powder (particle diameter is 50~150 μm), concentrated nitric acid, concentrated sulfuric acid and potassium permanganate, with mass ratio (0.5~2):(0.5~2):(0.2~1.5):( 0.2 to 1.5) into the reaction vessel, stirred and mixed to obtain a dark brown viscous liquid. Subsequently, wash the viscous liquid with water (to PH = 6.8-7.2) and dry (dry at a temperature of 50-90°C for 10-20h), and then immediately put the dried sample into a crucible with a temperature of 800-1000°C , cover the crucible lid, and obtain the expanded graphite sample when the crucible is cooled to room temperature. Then get expanded graphite, potassium persulfate and phosphorus pentoxide, in the ratio of (1~5):(1~4):(1~4) in mass ratio in the concentrated sulfuric acid of 80 ℃ and insulate and stir for 1~8h, Then the solution is washed with water so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com