Photoelectric programmable multi-state memory based on thin film transistor structure and its preparation method

A thin-film transistor and memory technology, applied in the field of multi-state memory and its preparation, achieves the effects of low power consumption requirements, precise and controllable thickness, and low growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

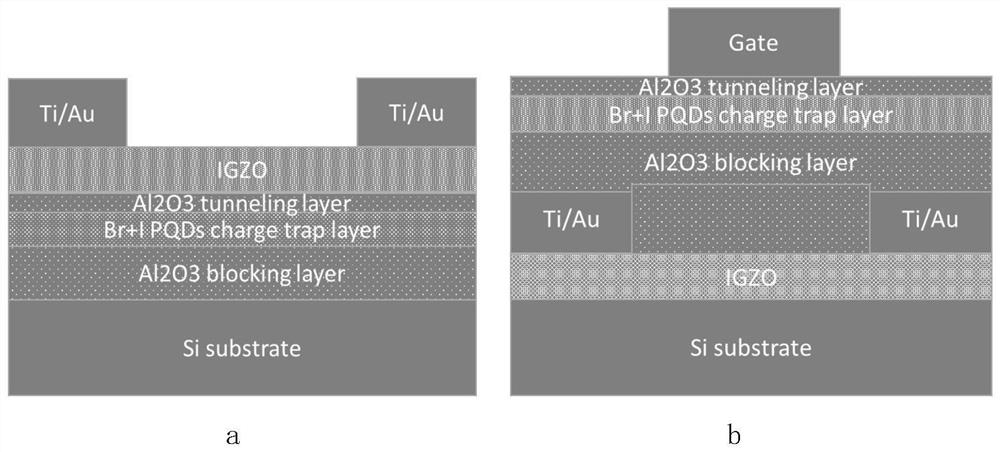

[0040] Embodiment 1 Bottom gate structure

[0041] Step 1, put the conductive substrate into the atomic layer deposition reaction chamber, the temperature range of the deposition chamber is 20°C-40°C, the temperature range of the TMA source bottle and each pipeline is 20°C-40°C, and vacuumize;

[0042] In step 2, an aluminum oxide barrier layer is prepared by atomic layer deposition. With trimethylaluminum and oxygen plasma as the reaction source, each cycle includes: 0.1s-2s trimethylaluminum pulse, 10s-30s nitrogen purge, 0.1s-10s oxygen plasma pulse, 10s-30s nitrogen purge sweep. Thickness range 30nm-50nm;

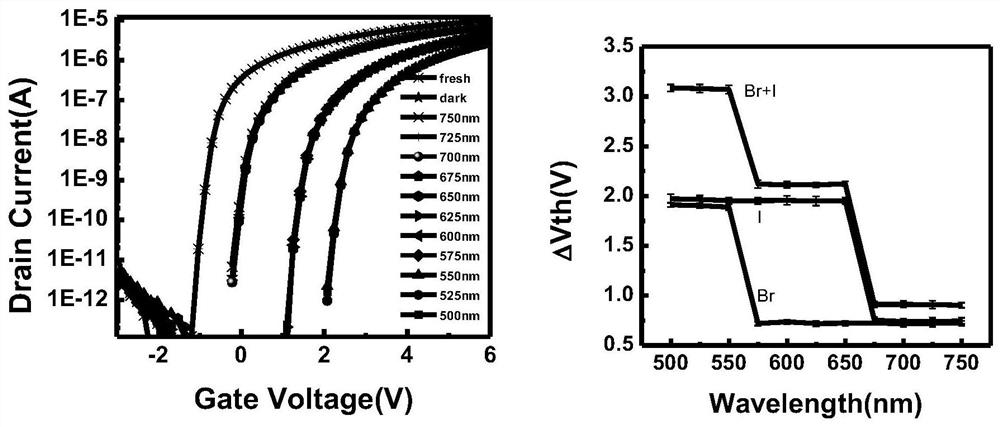

[0043] Step 3, with PbBr2, CsBr, PbI2, CsI, dimethylformamide, oleic acid, oleylamine, anhydrous toluene, methyl acetate, normal hexane etc., solution method prepares CsPbBr3, CsPbI3 perovskite quantum dot, and with Spin coating evenly on the barrier layer at a specific speed;

[0044] In step 4, an aluminum oxide tunneling layer is prepared by a low-temperature ato...

Embodiment 2

[0048] Example 2 Top Gate Structure

[0049] Step 1, put the substrate into the magnetron sputtering to grow the IGZO channel layer, define the channel pattern by ultraviolet lithography, and etch with dilute hydrochloric acid;

[0050] Step 2, define the pattern of the source and drain electrodes by photolithography again, remove the glue with acetone, and evaporate the Ti / Au source and drain electrodes by electron beam. Thickness range 70nm-130nm;

[0051] Step 3, put it into the atomic layer deposition reaction chamber, the temperature range of the deposition chamber is 20°C-40°C, the temperature range of the TMA source bottle and each pipeline is 20°C-40°C, and vacuumize;

[0052] In step 4, an aluminum oxide barrier layer is prepared by atomic layer deposition. With trimethylaluminum and oxygen plasma as the reaction source, each cycle includes: 0.1s-2s trimethylaluminum pulse, 10s-30s nitrogen purge, 0.1s-10s oxygen plasma pulse, 10s-30s nitrogen purge sweep. Thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com