Preparation method of corrosion-resistant double coatings of improved sintered Nd-Fe-B magnet

A technology of NdFeB and corrosion resistance, which is applied in the direction of coating, surface reaction electrolytic coating, metal material coating process, etc., can solve the problem of reducing the magnetic properties of magnets, limited effect, reducing the coercive force and magnetic energy product of magnets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a preparation method for improving the corrosion resistance of a sintered NdFeB magnet, comprising the following steps:

[0032] S1. Pickling, derusting and degreasing treatment: Put the sintered NdFeB magnet N35 into a nitric acid solution with a mass fraction of 5% for pickling for 30s to remove the rust and grease on the surface of the sintered NdFeB magnet;

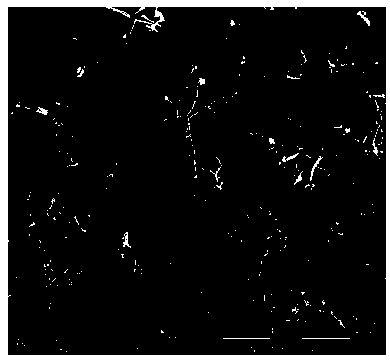

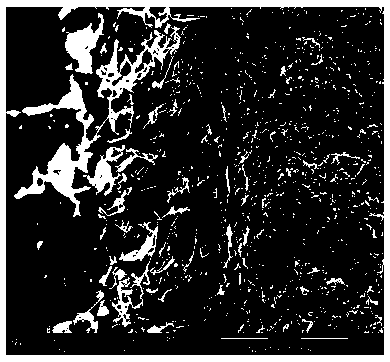

[0033] S2. Micro-arc oxidation treatment: put the sintered NdFeB magnet after the pickling treatment in step S1 into the electrolyte prepared by sodium aluminate, sodium hypophosphite and deionized water for micro-arc oxidation treatment, wherein the sodium aluminate The concentration of sodium hypophosphite is 12.3g / L, and the concentration of sodium hypophosphite is 1g / L; the micro-arc oxidation treatment adopts a bidirectional pulsed micro-arc oxidation power supply, with neodymium iron boron as the positive pole and a stainless steel electrolytic cell as the negative pole, and controll...

Embodiment 2

[0042] The invention provides a method for preparing a double coating for improving the corrosion resistance of sintered NdFeB magnets, comprising the following steps:

[0043] S1. Pickling, derusting and degreasing treatment: Put the sintered NdFeB magnet N35 into a nitric acid solution with a mass fraction of 5% for pickling for 30s to remove the rust and grease on the surface of the sintered NdFeB magnet;

[0044]S2. Micro-arc oxidation treatment: put the sintered NdFeB magnet after the pickling treatment in step S1 into the electrolyte prepared by sodium aluminate, sodium hypophosphite and deionized water for micro-arc oxidation treatment, wherein the sodium aluminate The concentration of sodium hypophosphite is 12.3g / L, and the concentration of sodium hypophosphite is 1g / L; the micro-arc oxidation treatment adopts a bidirectional pulsed micro-arc oxidation power supply, with neodymium iron boron as the positive pole and a stainless steel electrolytic cell as the negative p...

Embodiment 3

[0051] The invention provides a preparation method for improving the corrosion resistance of a sintered NdFeB magnet, comprising the following steps:

[0052] S1. Pickling, derusting and degreasing treatment: put the sintered NdFeB magnet N35 into a nitric acid solution with a mass fraction of 4% for pickling for 35s to remove the rust and grease on the surface of the sintered NdFeB magnet;

[0053] S2. Micro-arc oxidation treatment: put the sintered NdFeB magnet after the pickling treatment in step S1 into the electrolyte prepared by sodium aluminate, sodium hypophosphite and deionized water for micro-arc oxidation treatment, wherein the sodium aluminate The concentration of sodium hypophosphite is 20g / L, and the concentration of sodium hypophosphite is 1.5g / L; the micro-arc oxidation treatment adopts a bidirectional pulse micro-arc oxidation power supply, with neodymium iron boron as the positive pole and a stainless steel electrolytic cell as the negative pole, and controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com