High-temperature high-cycle negative electrode active material and preparation method thereof and nickel-metal hydride battery

A technology of negative electrode active material and nickel-hydrogen battery, which is applied in the direction of active material electrode, nickel storage battery, alkaline storage battery, etc., can solve the problems of short cycle life, poor long-term charging and discharging performance, and reducing the effective capacity of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] In one embodiment, a high-temperature and high-cycle negative electrode active material contains hydrogen storage alloy powder, and the hydrogen storage alloy powder includes a plurality of hydrogen storage alloy particles, and the hydrogen storage alloy particles have the general formula R 1-a Mg a Y b Ni c-d-e Al d T e The composition shown, wherein, R includes La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ca, Sr, Sc, Ti, Zr and Hf At least one of them, T includes at least one of Mn, Co, V, Nb, Ta, Cr, Mo, Fe, Ga, Zn, Sn, In, Cu, Si, P and B, a satisfies 0<a≤0.2 , b satisfies 0<b≦0.2, c satisfies 3≦c≦4, d satisfies 0<d≦0.50, and e satisfies 0<e≦1. It should be noted that the present invention adjusts the equilibrium pressure of the hydrogen storage alloy powder during hydrogen adsorption / desorption by adding suitable content of R and Y in the hydrogen storage alloy powder; by adding a suitable content of Mg in the hydrogen storage alloy powder , to...

Embodiment 1

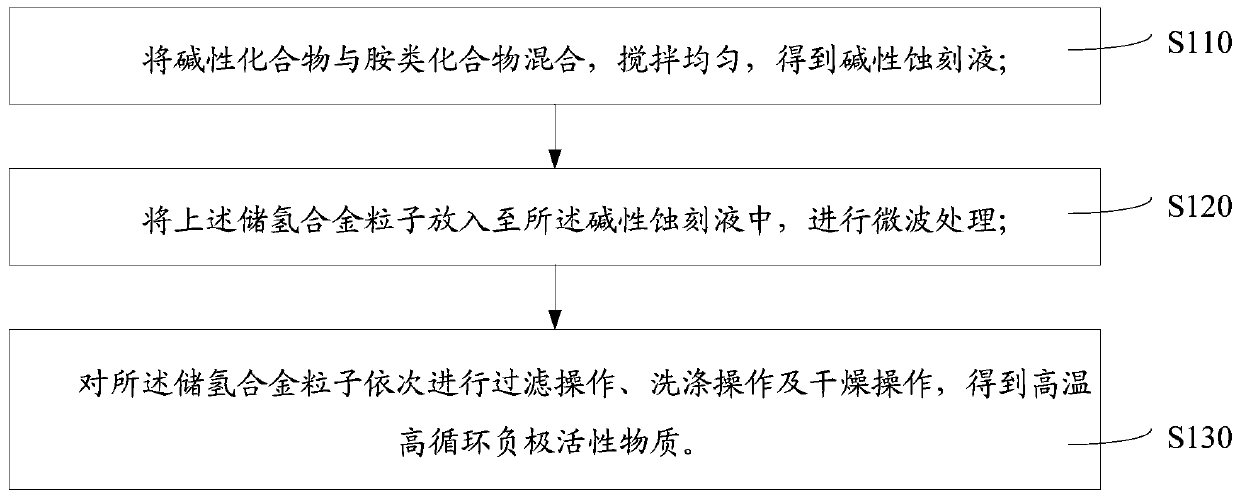

[0041] S111, mixing 100g of sodium hydroxide with 300g of methylamine, stirring evenly, to obtain an alkaline etching solution;

[0042] S121, put the hydrogen storage alloy particles into the alkaline etching solution, and conduct microwave treatment at a temperature of 50° C. with a frequency of 8000 MHZ for 5 minutes; wherein, the hydrogen storage alloy particles include 10 g of 60 nm in diameter Large particles of hydrogen storage alloy, 10g of medium particles of hydrogen storage alloy with a diameter of 40nm and small particles of hydrogen storage alloy with a diameter of 20nm in 10g have the general formula Pr 0.9 Mg 0.05 Y 0.05 Ni 3.8 Al 0.1 mn 0.1 composition shown.

[0043] S131, sequentially performing a filtering operation, a washing operation, and a drying operation on the hydrogen storage alloy particles to obtain a high-temperature, high-cycle negative electrode active material.

[0044]S141, using the high-temperature and high-cycle negative electrode act...

Embodiment 2

[0046] S112, mixing 100g of ammonia water with 600g of diethylamine, stirring evenly, to obtain an alkaline etching solution;

[0047] S122, put the above-mentioned hydrogen storage alloy particles into the alkaline etching solution, pass through microwaves with a frequency of 5000MHZ at a temperature of 80°C to conduct microwave treatment for 20 minutes; wherein, the hydrogen storage alloy particles include 10g of particles with a diameter of 150nm 10g of hydrogen storage alloy particles with a diameter of 100nm and 10g of hydrogen storage alloy particles with a diameter of 50nm have the general formula Ce 0.6 Mg 0.2 Y 0.2 Ni 1.5 Al 0.5 sn 1 composition shown.

[0048] S130, sequentially performing a filtering operation, a washing operation, and a drying operation on the hydrogen storage alloy particles to obtain a high-temperature, high-cycle negative electrode active material.

[0049] S140, using the high-temperature high-cycle negative electrode active material to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com