A method for synergistic vulcanization and roasting of lead-zinc smelting slag and gypsum slag

A technology of smelting slag and gypsum slag, which is applied in the direction of solid separation and flotation, can solve the problems of high energy consumption, environmental pollution, gypsum slag and dangerous solid waste accumulation in the treatment process, and achieve the effect of promoting growth and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

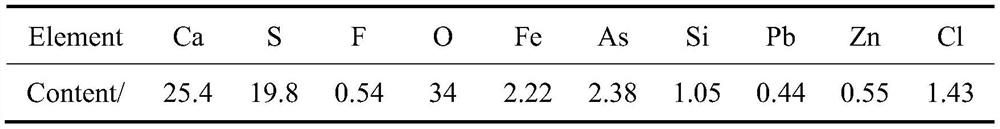

[0029] The vulcanizing agent used in this example is the gypsum neutralization slag produced by the electrolytic clean solution of a certain zinc factory. The specific components are shown in Table 1. The main components of the neutralization slag are dihydrate and calcium sulfate, containing 2.38% arsenic;

[0030] Main chemical composition / % of the slag in Table 1

[0031]

[0032]

[0033] The lead-zinc smelting slag used in this example is acidic leaching slag, and its specific composition is shown in Table 2. Zinc in the zinc leaching slag mainly exists in the form of zinc ferrite;

[0034] Table 2 Main chemical composition / % of zinc ferrite slag

[0035]

[0036] A method for synergistic vulcanization and roasting of lead-zinc smelting slag and gypsum slag, the specific steps are as follows:

[0037] (1) Get above-mentioned 1000kg gypsum slag, 800kg zinc leaching slag and 300kg particle size respectively and be that 80% are less than 5mm coke mixing (mass ratio i...

Embodiment 2

[0053] The vulcanizing agent used in this example is the desulfurization gypsum slag produced in the flue gas acid washing process of a zinc smelter plant. The specific components are shown in Table 5. The main components of the neutralization slag are dihydrate and calcium sulfate, containing 0.18% arsenic;

[0054] Table 5 Main chemical composition of desulfurization gypsum slag / %

[0055]

[0056] The water-quenched slag used in this example is obtained from the zinc-containing slag produced by the blast furnace reduction smelting process of a fire-process lead smelting plant in Henan through water-quenching and rapid cooling. The slag is in a glassy state. , its specific composition is shown in Table 6, the water-quenched slag zinc mainly occurs as zinc silicate and zinc ferrite, and lead mainly occurs in the form of metallic lead and lead oxide;

[0057] Table 6 Main chemical composition of water-quenched slag / %

[0058]

[0059]

[0060] A method for synergisti...

Embodiment 3

[0077] The vulcanizing agent used in this example is the desulfurized gypsum slag produced during the acid washing process of flue gas from a zinc smelter. blast furnace dust, the particle size of this material is 75% less than 0.074mm, and the material is fine and can be used directly. The specific composition is shown in Table 9. The zinc in this material is mainly zinc oxide, zinc silicate and zinc ferrite. Hematite, Exist in the form of iron silicate and ferric oxide;

[0078] Table 9 The main chemical components of steel plant dust / %

[0079]

[0080] A method for synergistic vulcanization and roasting of lead-zinc smelting slag and gypsum slag, the specific steps are as follows:

[0081] (1) get the above-mentioned 1000kg gypsum slag, 750kg zinc leaching slag and 250kg particle size respectively and be that 80% are less than 5mm anthracite mixing (mass ratio is 100:75:25);

[0082] (2) Place the above-mentioned mixed sample on the steel belt furnace distribution mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com