Flexible circuit board base material based on quantum carbon base film and preparation method thereof

A flexible circuit board and carbon-based film technology, which is applied in the manufacture of printed circuits, the improvement of the metal adhesion of insulating substrates, printed circuits, etc., can solve the problems of poor thermal conductivity of FPC, increased Joule heating, circuit fusing, etc., and achieve thermal and electrical conduction Good performance, improved reliability, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

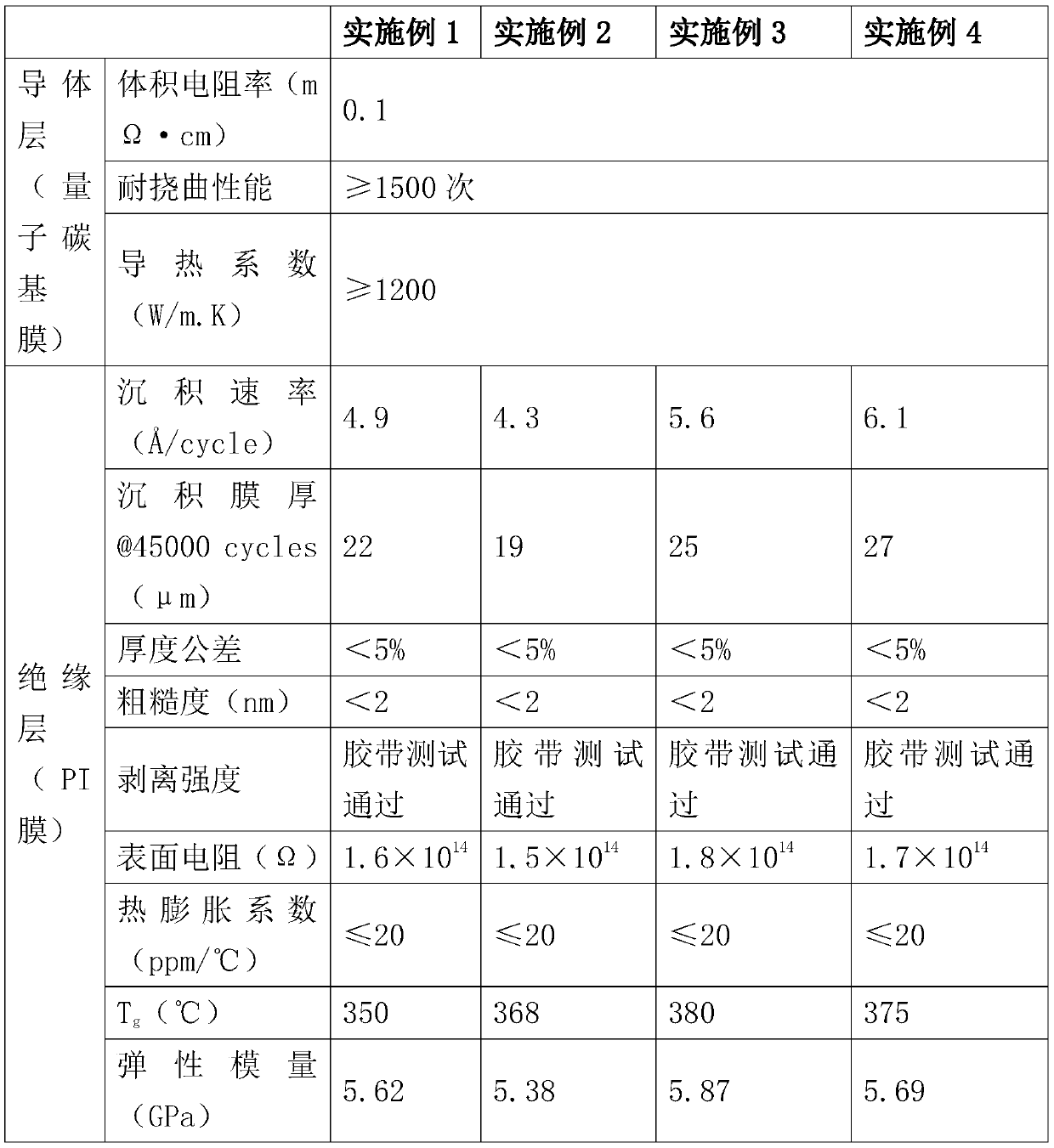

Examples

preparation example Construction

[0034] In an embodiment of the second aspect of the present invention, a method for preparing a quantum carbon-based film-based flexible circuit board substrate includes the following steps:

[0035] S1. Plasma modification treatment is carried out on the surface of the quantum carbon-based film, preferably argon plasma, but an acrylic acid graft layer is produced on the surface of the quantum carbon-based film through a grafting reaction;

[0036] S2. Depositing a PI film on the surface of the quantum carbon-based film by CVD chemical vapor deposition reaction.

[0037] The invention uses the quantum carbon-based film to replace the copper foil in the traditional FCCL to prepare a flexible printed circuit board (FPC) base material with high thermal conductivity and high conductivity. The quantum carbon-based film used in the present invention can be a flexible carbon-based film with high conductivity, super flexibility, high thermal conductivity and high frequency obtained by...

Embodiment 1

[0073] Raw materials:

[0074] 3,3’,4,4’-Biphenyltetracarboxylic dianhydride

[0075] m-phenylenediamine

[0076] Nitrogen (carrier / cleaning gas)

[0077] Quantum carbon-based film (thickness: 20μm)

[0078] steam

[0079] instrument:

[0080] CVD vapor deposition device (Finland)

[0081] PEO601 RTA rapid thermal annealing furnace (Germany)

[0082] Preparation steps:

[0083] S1: Argon plasma modification treatment on the surface of the quantum carbon-based film, the steps are as follows:

[0084] (1) Place the quantum carbon-based film in acetone solution or absolute ethanol, clean it with ultrasonic waves, and then vacuum dry it in a vacuum drying oven;

[0085] (2) Argon plasma treatment is carried out after the treatment is completed, the plasma treatment power is 70W, the working pressure is 70Pa, and the treatment time is 15min;

[0086] (3) After the surface of the quantum carbon-based film is modified by plasma, then chemical treatment is used to graft on th...

Embodiment 2

[0096] The difference from Example 1 is that this is PI prepared from monomer raw materials 2,3,3',4'-diphenyl ether tetraacid dianhydride and 3,3'-diaminodiphenyl ether in quantum carbon CVD vapor deposition on the surface of the base film, the deposition cycle and reaction conditions are: 2,3,3',4'-diphenyl ether tetraacid dianhydride gas pulse (deposition temperature: 170 ° C, pulse time: 3.0s)-N 2 (Purge time: 1.5-3.0s)-3,3’-Diaminodiphenyl ether gas pulse (deposition temperature: 150°C, pulse time: 2.0s)-N 2 (Purge time: 1.5-3.0s). All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com